A kind of durable rubber asphalt and preparation method thereof

A rubberized asphalt, durable technology, applied in the field of durable rubberized asphalt and its preparation, can solve the problems of large durability, rutting, cracks and potholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

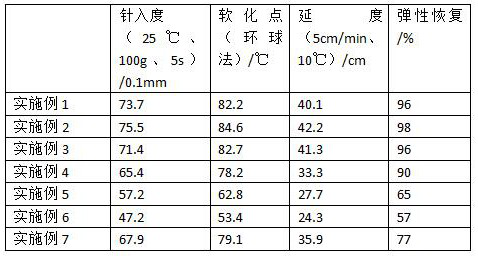

Examples

Embodiment 1

[0018] A durable rubber asphalt, consisting of the following components in parts by weight: 100 parts of base asphalt, 20 parts of rubber powder, 0.3 parts of foaming agent, 0.2 parts of foam stabilizer, 0.05 parts of stabilizer, and 0.1 part of defoamer 10 parts, 10 parts of γ-aminopropyltriethoxysilane, 10 parts of rare earth tungstate.

[0019] Above-mentioned foaming agent is fatty alcohol polyoxyethylene ether sodium sulfate.

[0020] The above-mentioned foam stabilizer is silicone resin polyether emulsion (MPS).

[0021] The aforementioned stabilizers are nitro-substituted diaryl disulfides.

[0022] The above-mentioned defoamer is simethicone.

Embodiment 2

[0024] A durable rubber asphalt, consisting of the following components in parts by weight: 100 parts of base asphalt, 25 parts of rubber powder, 0.4 parts of foaming agent, 0.4 parts of foam stabilizer, 0.1 part of stabilizer, and 0.15 parts of defoamer 15 parts, 15 parts of γ-aminopropyltriethoxysilane, 15 parts of rare earth tungstate.

[0025] Above-mentioned foaming agent is fatty alcohol polyoxyethylene ether sodium sulfate.

[0026] The above-mentioned foam stabilizer is silicone resin polyether emulsion (MPS).

[0027] The aforementioned stabilizers are nitro-substituted diaryl disulfides.

[0028] The above-mentioned defoamer is simethicone.

Embodiment 3

[0030] A durable rubber asphalt, consisting of the following components in parts by weight: 100 parts of base asphalt, 30 parts of rubber powder, 0.5 parts of foaming agent, 0.5 parts of foam stabilizer, 0.1 part of stabilizer, and 0.2 parts of defoamer 20 parts, 20 parts of γ-aminopropyltriethoxysilane, 20 parts of rare earth tungstate.

[0031] Above-mentioned foaming agent is fatty alcohol polyoxyethylene ether sodium sulfate.

[0032] The above-mentioned foam stabilizer is silicone resin polyether emulsion (MPS).

[0033] The aforementioned stabilizers are nitro-substituted diaryl disulfides.

[0034] The above-mentioned defoamer is simethicone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com