A method for efficient treatment of nitrogen-containing wastewater based on dissimilatory reduction of nitrate to ammonium combined with denitrification coupled with anaerobic ammonium oxidation

A technology of anaerobic ammonium oxidation and nitrate, which is applied in anaerobic digestion treatment, chemical instruments and methods, natural water treatment, etc., can solve the problems of weakening single treatment effect, achieve low COD and low temperature tolerance, and operate Simple, copy-enrichment-obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

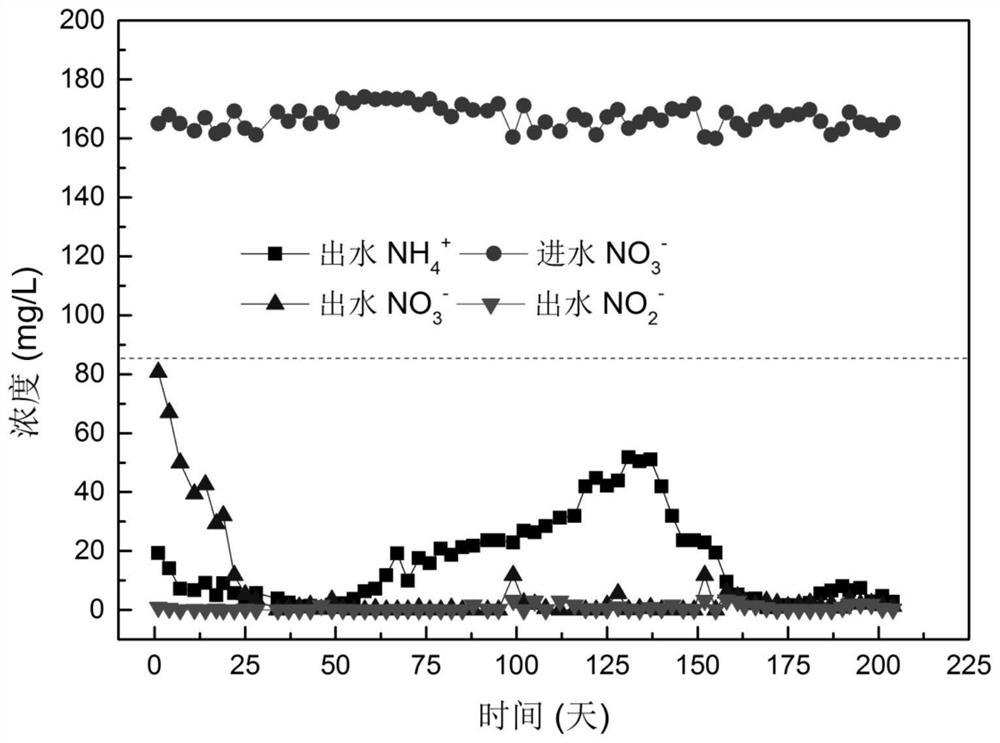

[0046] A method for treating nitrogen-containing wastewater based on dissimilatory reduction of nitrate to ammonium combined with denitrification coupled with anaerobic ammonium oxidation, comprising the following steps:

[0047] (1) Stir the aerobic activated sludge evenly and add it to the reaction zone of the anaerobic membrane bioreactor; The impurities in the sludge are obtained from leaves, waste paper, and waste plastics, and the moisture content of the aerobic activated sludge is greater than or equal to 98 wt %; the anaerobic membrane bioreactor is a submerged anaerobic membrane bioreactor, and the membrane is a non-woven membrane. The flux is 120L / m 2 / h; the membrane support is a polymethyl methacrylate support; the top of the anaerobic membrane bioreactor is provided with two water inlets;

[0048] (2) From the two water inlets on the top of the anaerobic membrane bioreactor, there are two water inlets, one for inorganic wastewater, and one for organic wastewater,...

Embodiment 2

[0055] With the method described in Example 1 based on nitrate dissimilation reduction to ammonium combined with denitrification coupling anaerobic ammonium oxidation treatment of nitrogenous wastewater, the difference is:

[0056] In step (2), the inlet flow rate of inorganic wastewater and organic wastewater is the same, and the inlet flow rate of inorganic wastewater and organic wastewater is controlled to be 75mL / h, and the total inlet flow rate is 150mL / h, so that the sewage to be treated in the anaerobic membrane bioreactor The internal hydraulic retention time is 40 hours, and the C / N of the wastewater is 10:1. A constant temperature circulating water bath device is used to maintain the internal temperature of the anaerobic membrane bioreactor at 22 degrees, and the anaerobic membrane bioreactor is fed to the anaerobic membrane bioreactor every 6 hours. Nitrogen gas is aerated for 20 min, and the aeration intensity is 5 mL / (L min). Preferably, the wastewater to be treate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com