Sliding rail clamp of infusion bottle

A technology for infusion bottles and slide rails, which is applied to packaging bottles, transportation and packaging, packaging, etc., can solve the problems of low production efficiency, low degree of automation, and high labor intensity of operators, so as to improve the smoothness and avoid pinching. bad or scratched effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

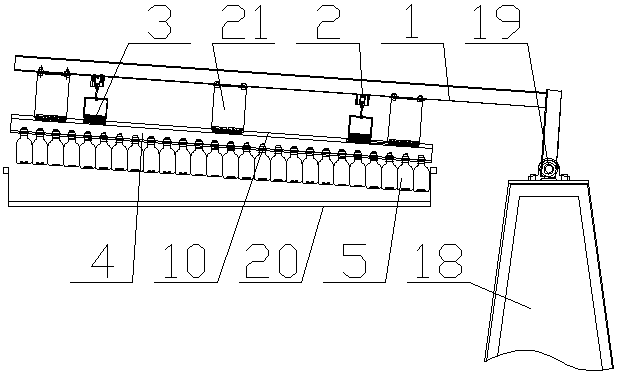

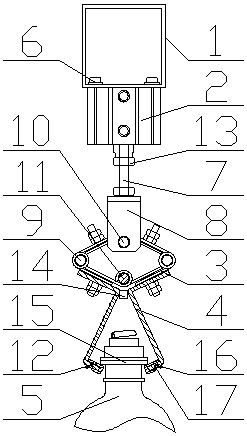

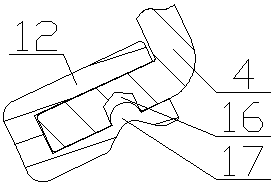

[0031] combine Figure 1~Figure 3 It can be seen that the present invention includes two symmetrical and parallel "Z"-shaped slide rail clamp arms 4, and the top of the "Z"-shaped slide rail clamp arms 4 is provided with a driving piston 2, and the driving piston 2 is fixed on the push rod 1. The ejector rod 1 extends along the length direction of the "Z"-shaped slide rail clamp arm 4, and the end of the driving piston rod 7 of the driving piston 2 protrudes downwards, and passes through the diamond-shaped structural frame 3 and the "Z"-shaped The slide rail clamp arm 4 is connected by transmission. The rhombus structure frame 3 includes a plurality of connecting plates connected in sequence. The two sides of the connecting plates are respectively provided with bushings 9 alternately, and two adjacent connecting plates pass through the bushings 9 respectively. The shaft rods are connected by rotation, and the shaft sleeves 9 used to connect the upper two connecting plates are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com