Steadily-operated environment-friendly salvage ship

A salvage ship, environmental protection technology, applied in the cleaning of open water, water conservancy projects, construction, etc., can solve the problems of water pollution, large size of salvage ship, reduced cargo capacity, etc., to reduce production costs, increase salvage area, Guarantees the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

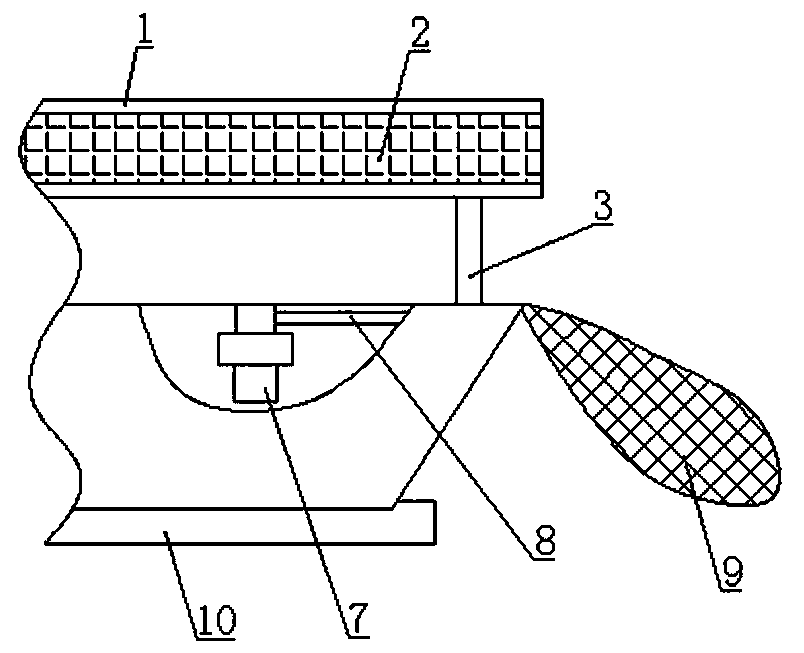

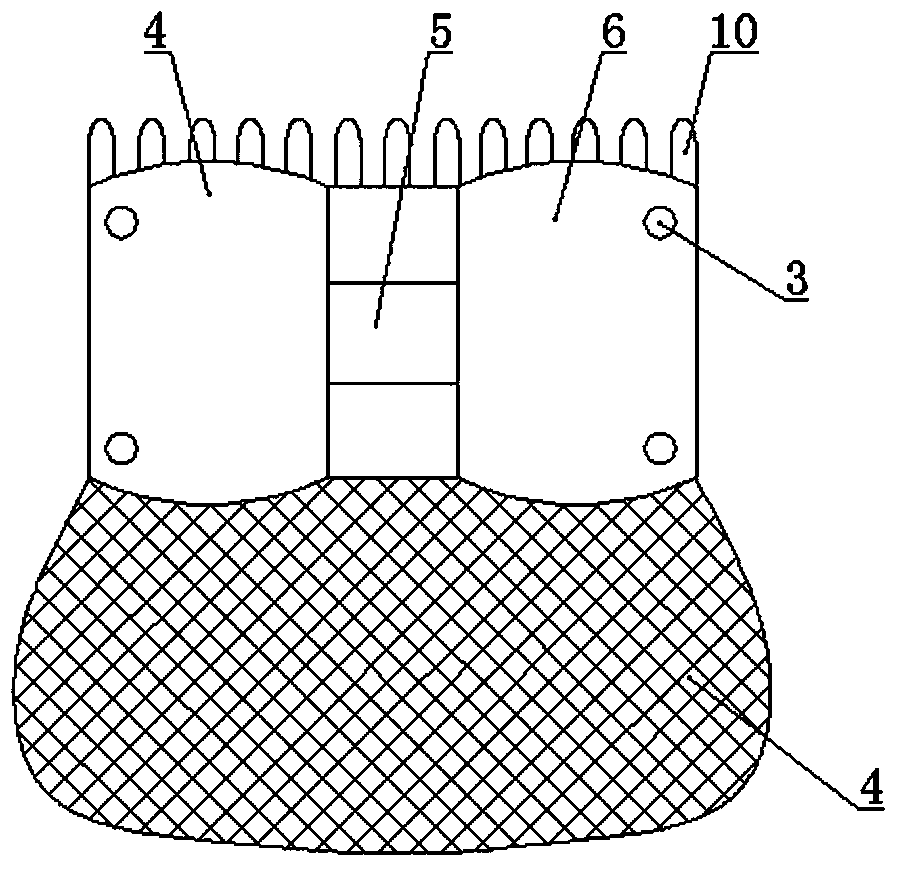

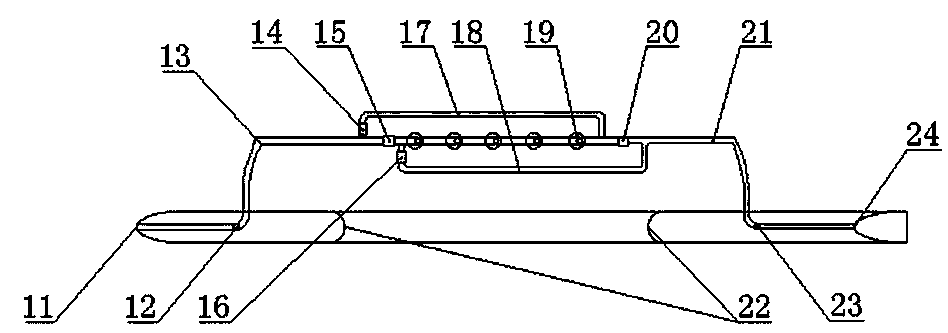

[0020] Such as Figure 1~3 As shown, a stable running environmentally friendly salvage ship mainly includes a hull, the hull is composed of a left hull 4, a right hull 6 and a connecting cabin 5, and the connecting cabin 5 passes between the left hull 4 and the right hull 6 The welding connection is integrated, and the rear end of the hull is equipped with a salvage device. The connecting compartment 5 is provided with a packing purification area capable of pumping and draining water, and at least one purification cabin is arranged in the packing purification area, and packing is filled in the purification cabin.

[0021] Such as Figure 1~3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com