Electromagnetic mold locking injection molding machine

A technology of injection molding machine and electromagnetic lock, applied in the field of injection molding machine, can solve the problems of slipping locking, breakage, weakening magnetic force, etc., and achieve the effect of improving the locking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

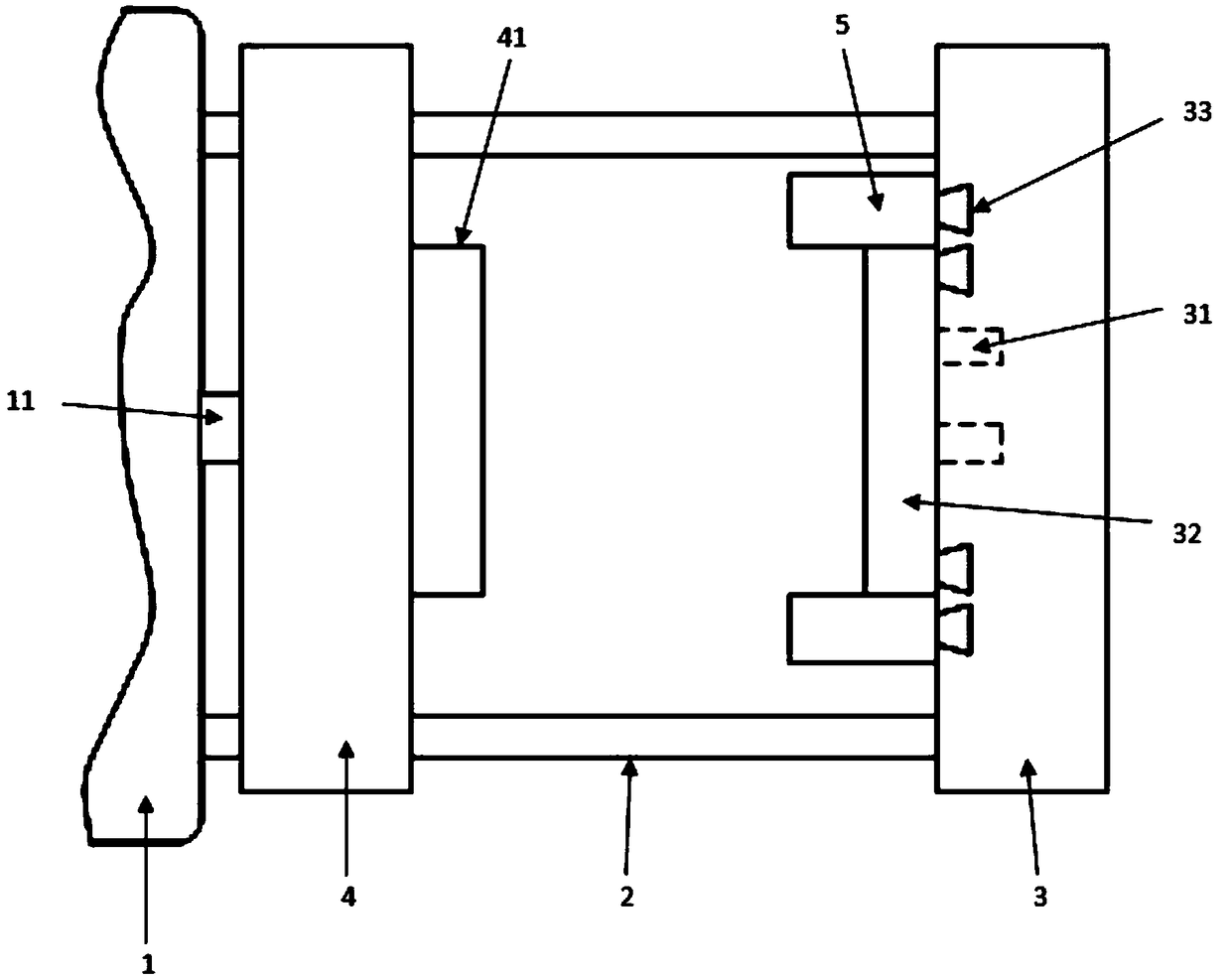

[0017] Such as figure 1 As shown, an electromagnetic clamping injection molding machine includes a frame 1, a guide post 2, a back seat 3 and a movable plate 4, and the frame 1 and the back seat 3 are provided with four guide posts 2 at a time, and the movable plate 4. The movable plate is threaded on the guide post 2 and the movable plate 4 is provided with a walking trolley corresponding to the guide post 2, so that the movable plate 4 can move back and forth along the guide post 2. The back seat 3 passes the bolt toward the movable plate 4 31 is equipped with a fixed mold 32, and the movable plate 4 is equipped with a movable mold 41 facing the side of the back seat. On the back seat 3 and above and below the bolts 31 are respectively provided with a plurality of card slots 33, and the card slots 33 pass through An electromagnet 5 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com