Laser and water jet combined machining system

A composite processing and water jet technology, which is used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems that hinder the application of laser high-pressure water jet composite processing technology, cannot block the optical path of the laser exit part, and cannot isolate the anti-sputtering device. Interference and other problems, to achieve the effect of improving the processing effect, stabilizing the optical path, and reducing the width of the scribing and cutting line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

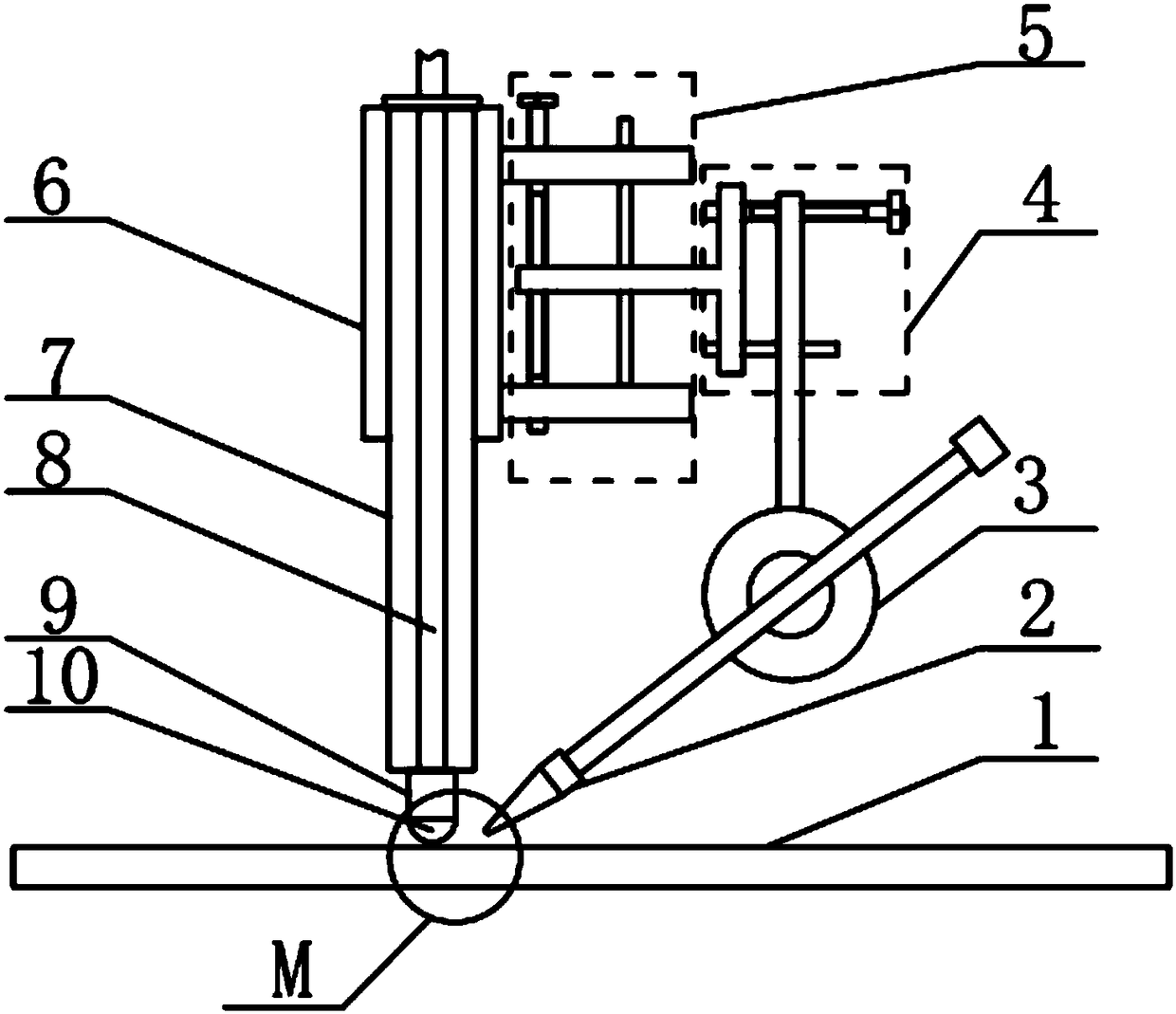

[0027] The structure of the embodiment of the laser water jet composite processing system is as follows figure 1 As shown, it includes a jet nozzle 2 connected with a water tank, a laser, and a workbench. The workbench surface is a horizontal plane, and the workpiece 1 is fixed on the workbench surface. The jet nozzle 2 emits a water jet, and the water jet falls on the processing path of the workpiece surface. The center line of the laser beam generated by the laser is perpendicular to the table surface.

[0028] The laser beam generated by the laser in this example propagates in the guiding optical fiber 8. The guiding optical fiber 8 of this example is located in the protective casing 7, and there is a supporting casing 6 outside the protective casing 7. The supporting casing 6 fixes the protective casing 7 and Fixed connection with the rack. The end of the guiding optical fiber 8 is connected to the diamond guiding head 10 via the laser shaper 9.

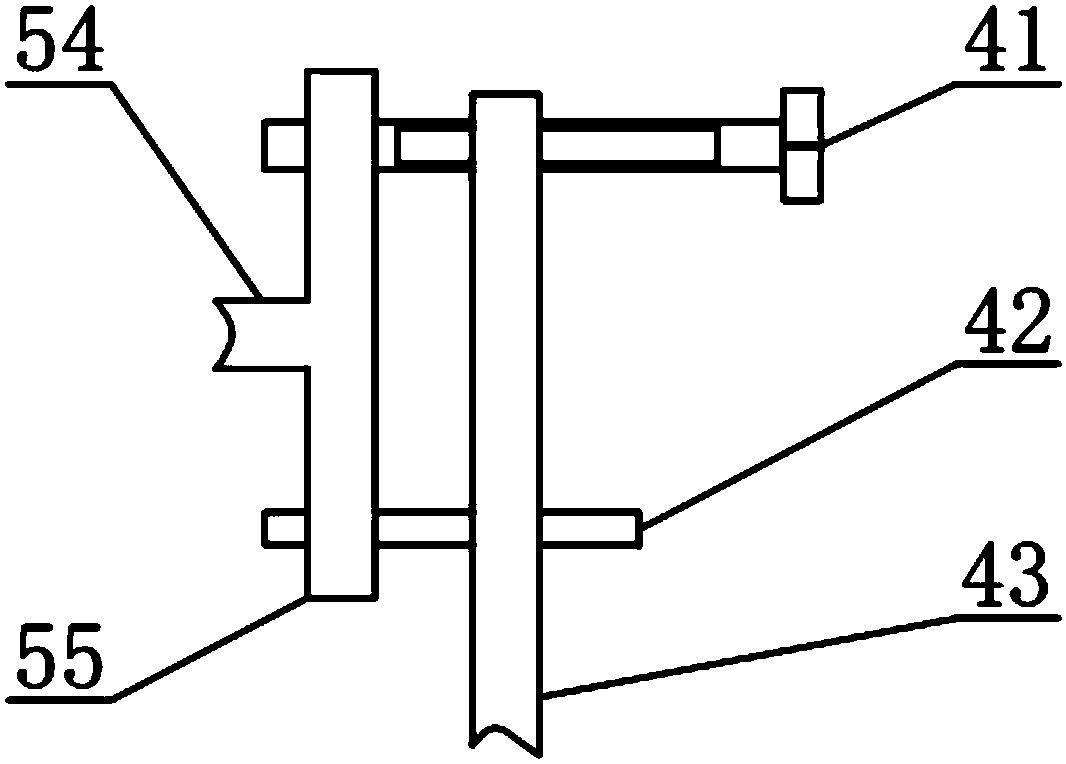

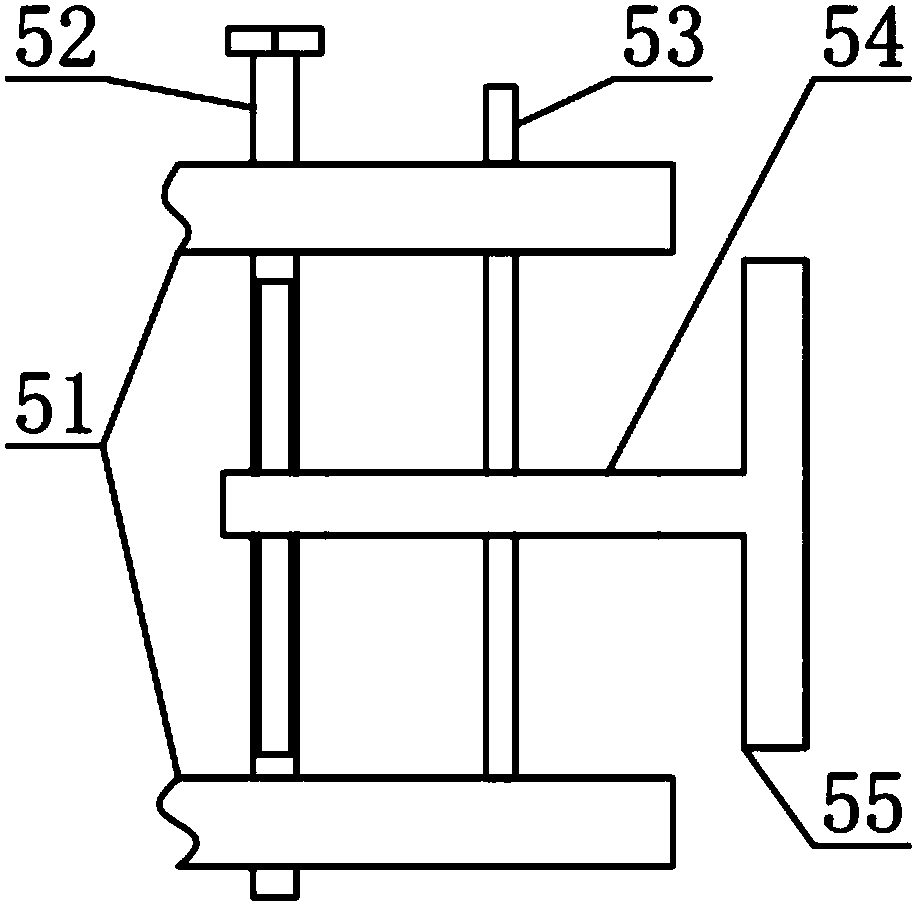

[0029] Such as Figure 4 wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com