Press device FOR TEST SORTER

A technology for testing sorting machines and pressurizing devices. It is applied in the direction of measuring devices, sorting, and measuring electricity. It can solve the problems of large changes in the position of the pushing part and difficulty in applying it properly, and achieve the effect of precise electrical connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

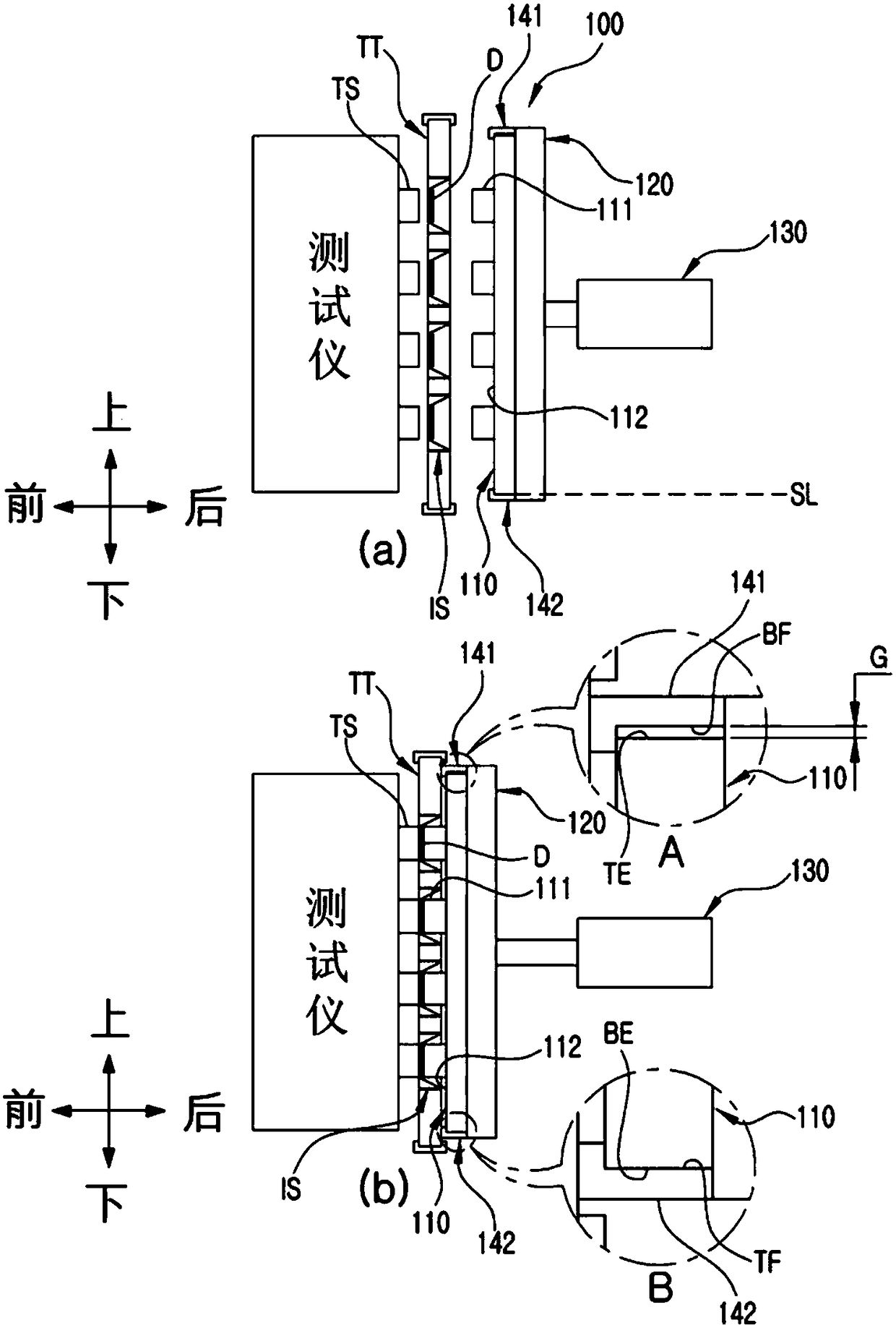

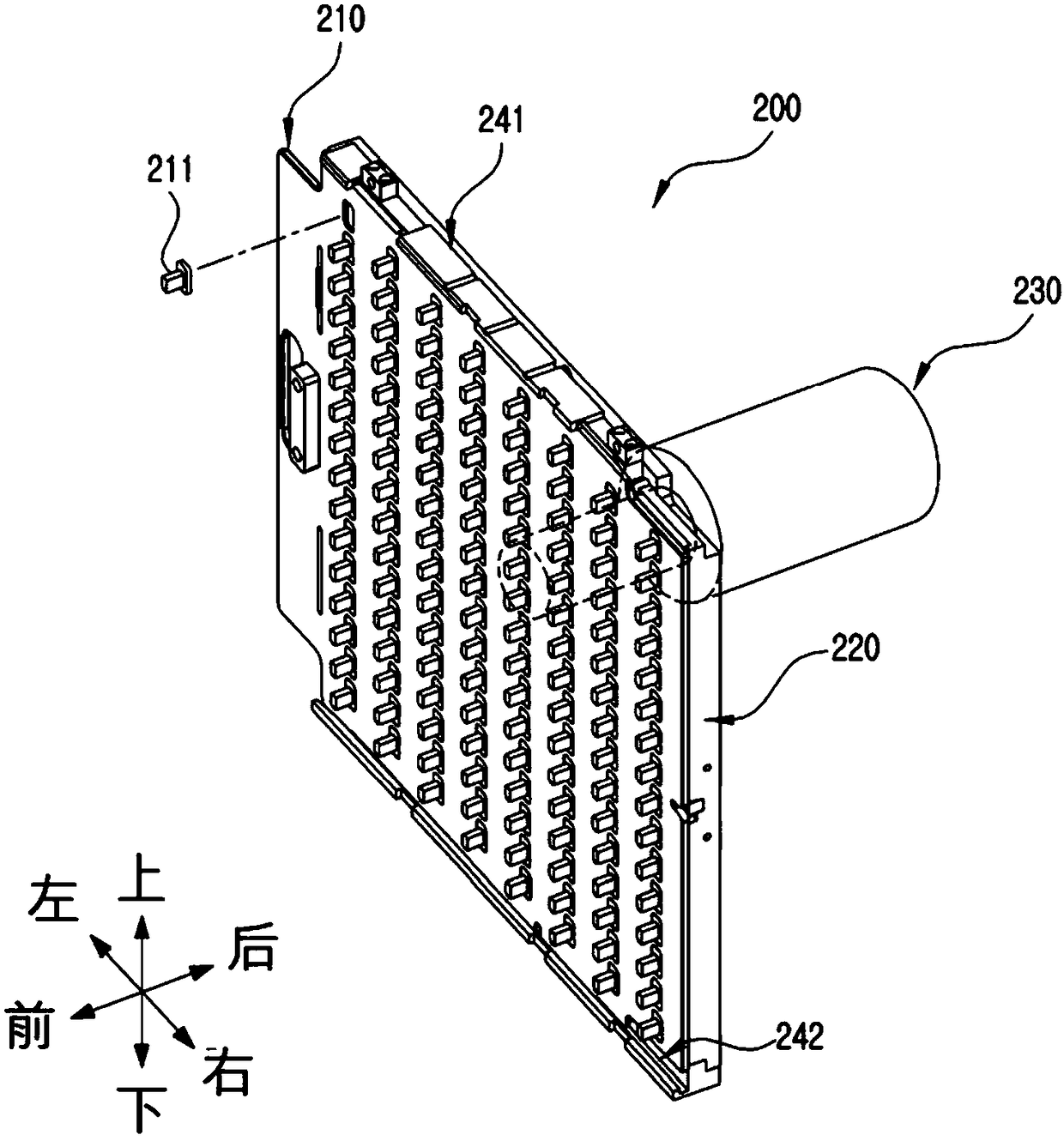

[0062] The preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. For the sake of brevity, descriptions of repeated or substantially identical structures will be omitted or compressed as much as possible.

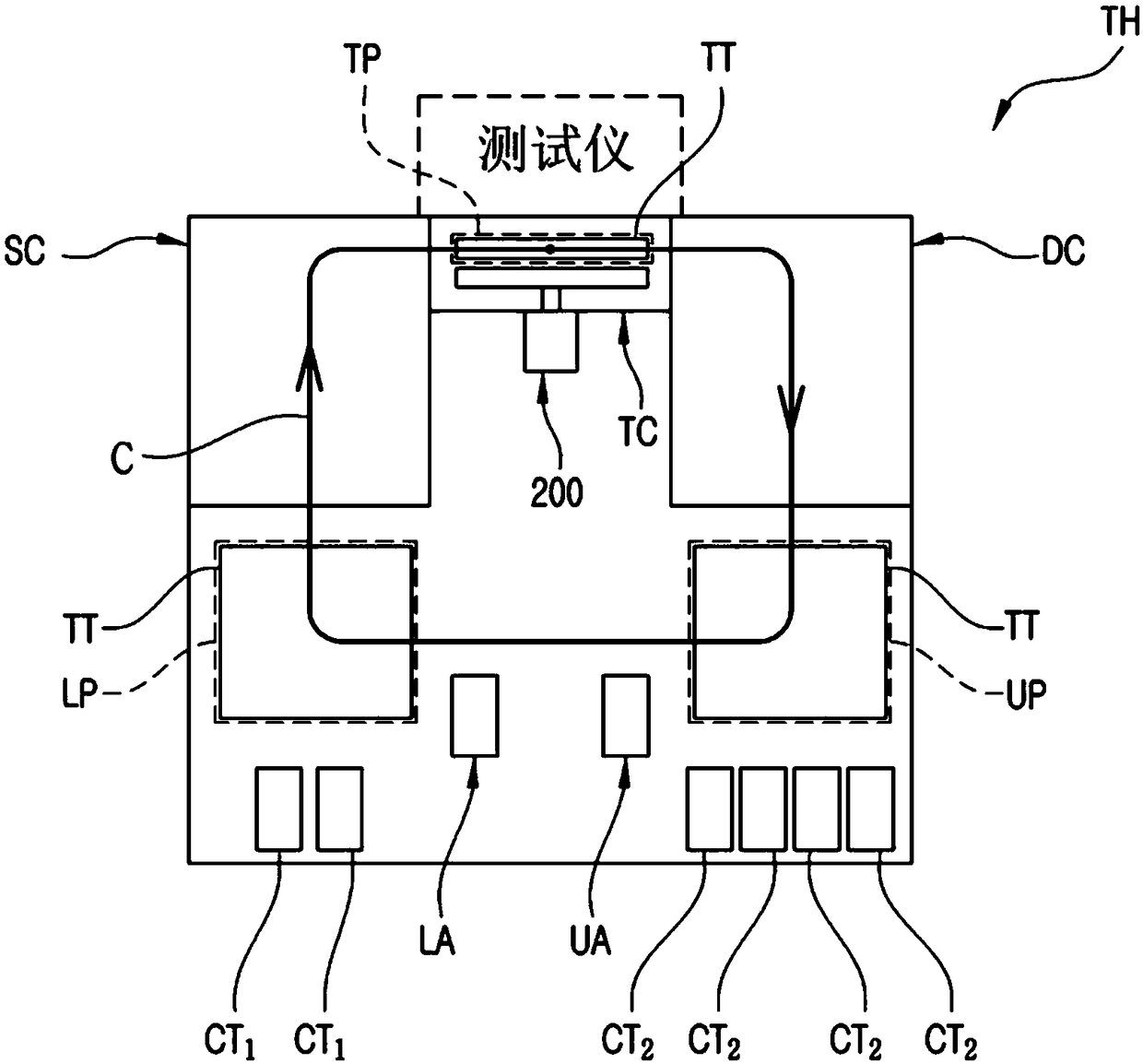

[0063] A Brief Description of the Test Sorter

[0064] figure 2 This is a conceptual plan view of a test handler TH to which the pressurizing device 200 for a test handler of the present invention (hereinafter simply referred to as a pressurizing device) is applicable.

[0065] The test handler TH comprises a loading device LA, a soaking chamber SC, a testing chamber TC, a pressurizing device 200, a heat removal chamber DC and an unloading device UA.

[0066] The loading device LA moves a plurality of semiconductor devices to be tested loaded on the customer tray CT1 to the test tray located at the loading position LP.

[0067] The soaking chamber SC is used to apply a thermal stimulus to a plurality of sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com