Pneumatic small-particle-size atomization spray head

A technology of atomizing nozzle and small particle size, which is applied in the direction of spray discharge device, etc., which can solve the problems of increasing system cost, wasting spray liquid, and prone to clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

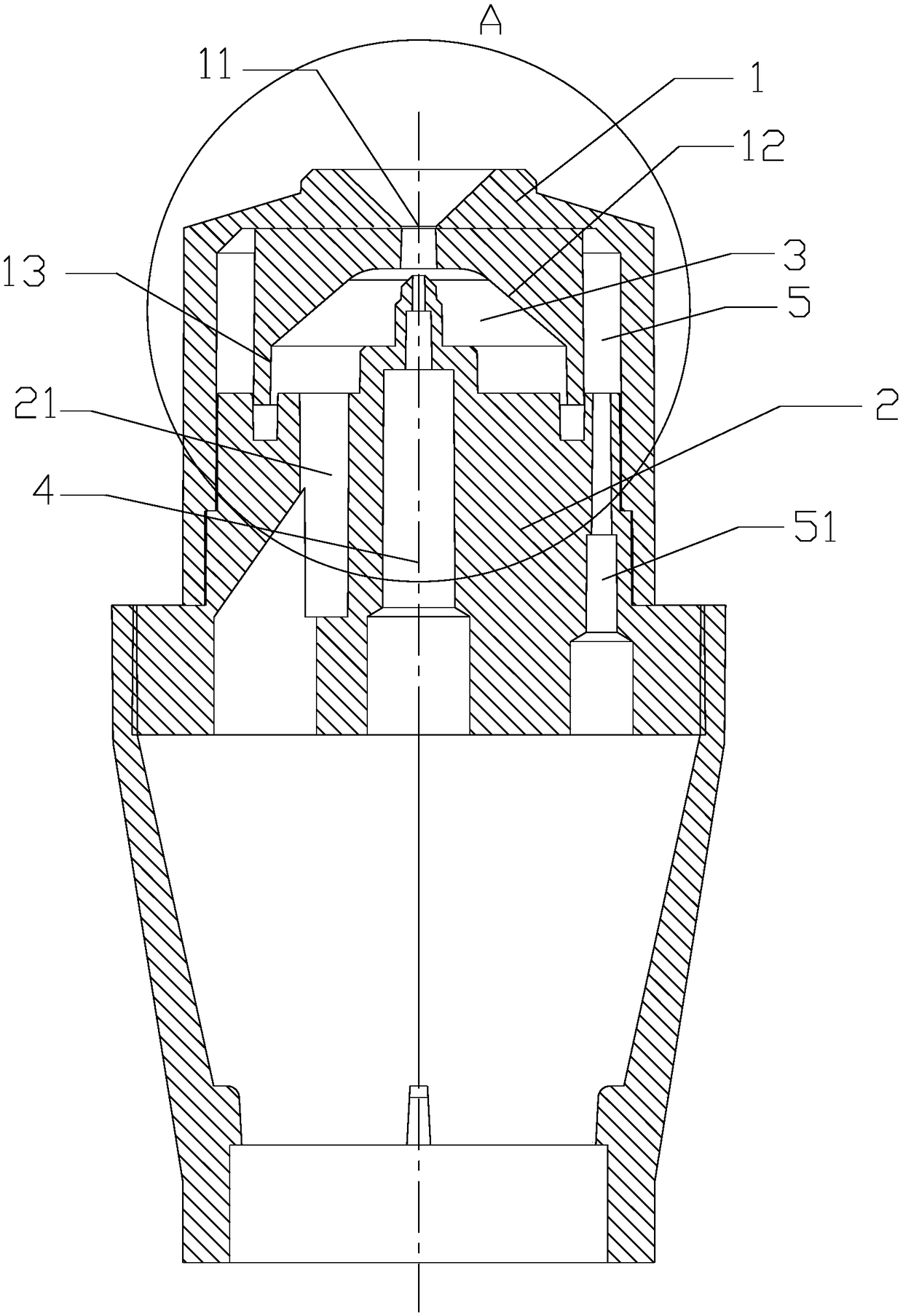

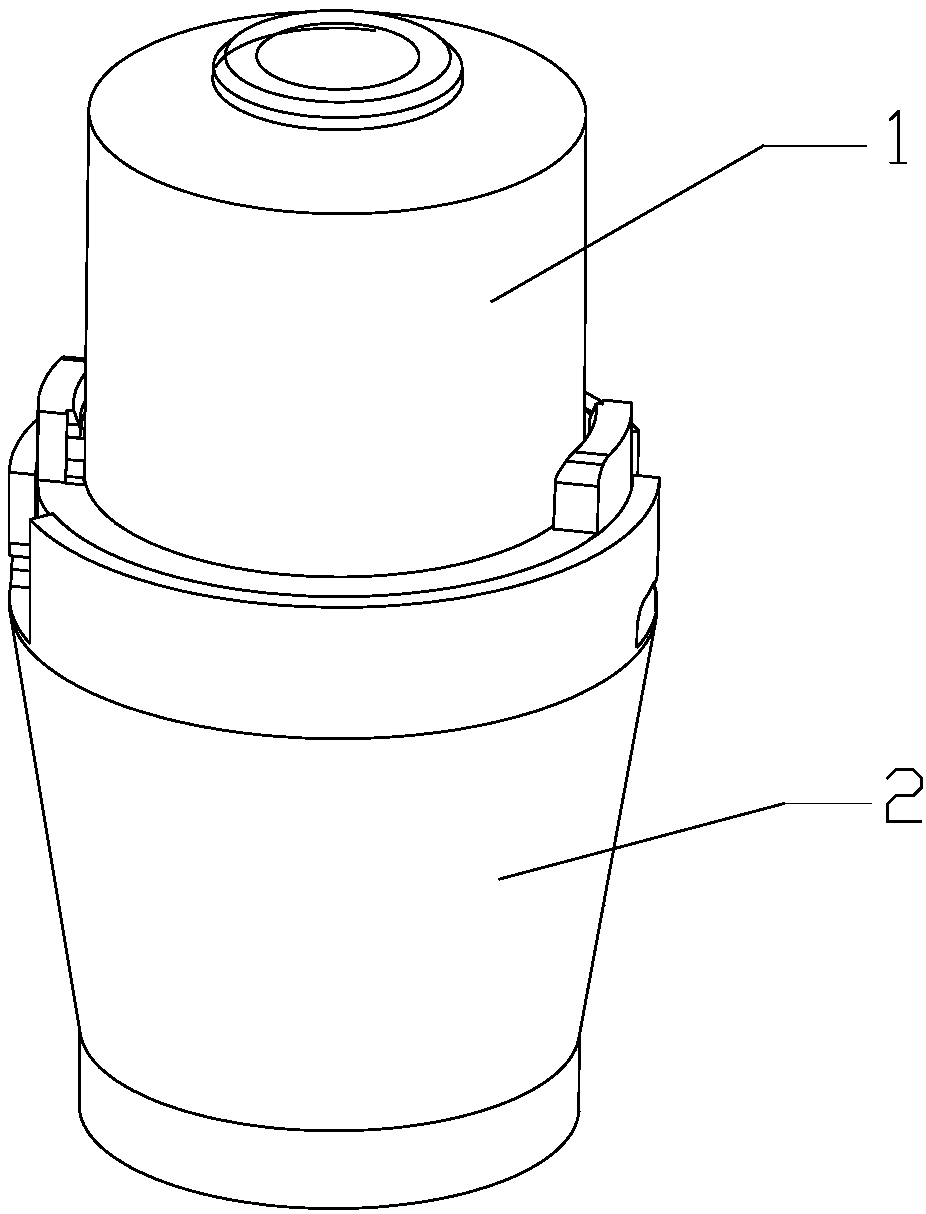

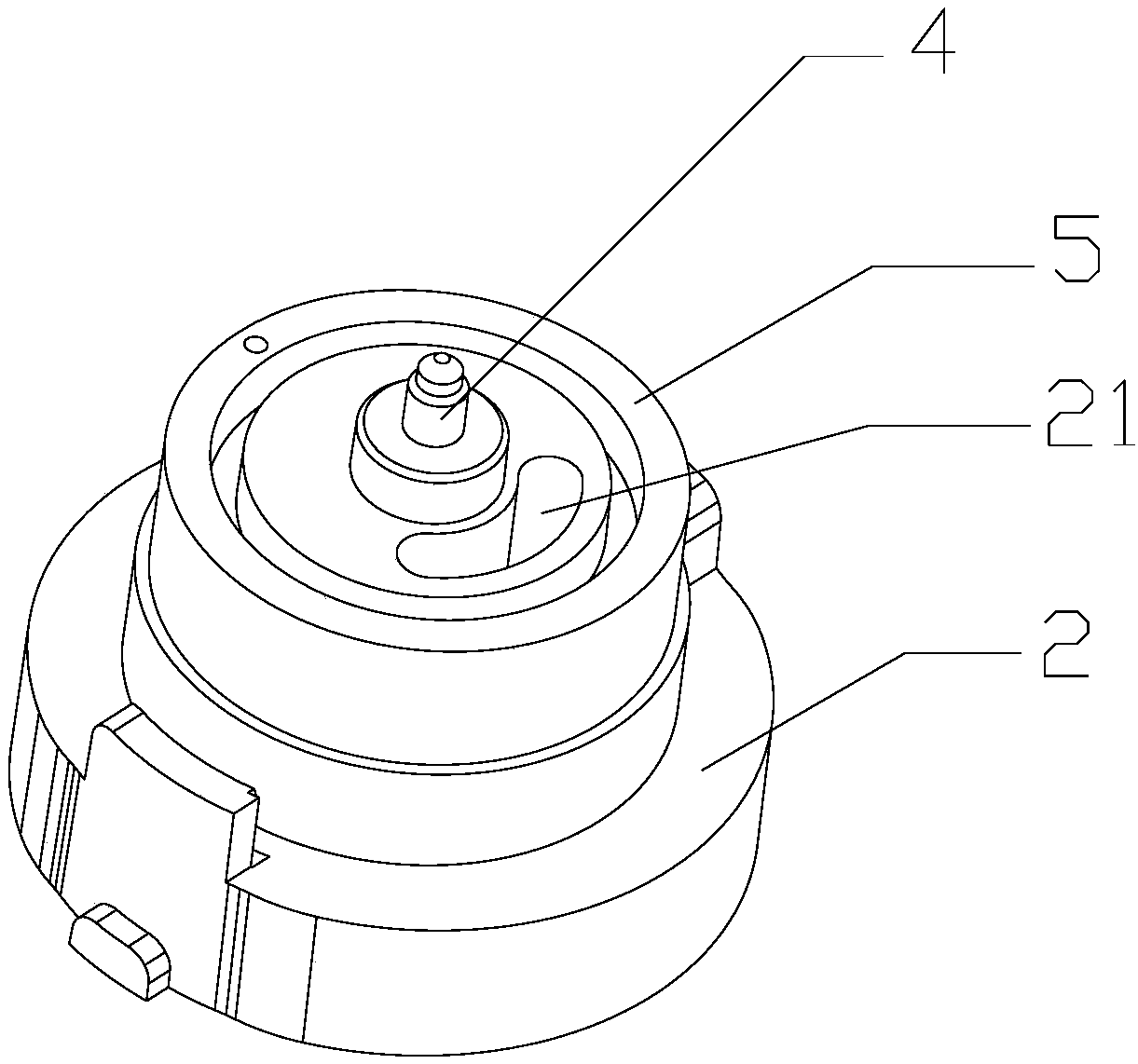

[0026] Such as Figure 1 to Figure 4 As shown, a preferred embodiment of the present invention provides a pneumatic small particle size atomizing nozzle, including a nozzle body 2, an air knife assembly and an end cap 1 installed on the nozzle body 2. The nozzle body 2 is provided with a The liquid outlet pipe 4 for the liquid drop, the end cover 1 surrounds the end of the liquid outlet pipe into an air chamber 3, and a nozzle 11 corresponding to the position of the end of the liquid outlet pipe is arranged on it, and the air knife assembly is used In the air chamber, the airflow between the end of the liquid outlet pipeline and the nozzle is formed, and the nozzle is used to eject liquid droplets and gas; the air knife assembly includes a gas that is arranged on the main body of the nozzle 2 and is used to input gas into the air chamber. The groove 21, the gas channel 13 for guiding the gas flow, and the inclined surface 12 arranged inside the end cover and used for refractin...

Embodiment 2

[0033] This embodiment provides a test method for detecting the particle size distribution of the liquid droplets sprayed by the atomizing nozzle, so as to obtain a pneumatic small particle size atomizing nozzle with an optimal structure.

[0034] In the test, the Winner318B laser particle size analyzer was used to measure the particle size of the atomized liquid droplets in the horizontal and vertical directions. In order to ensure the measurement accuracy of the system, the laser particle size analyzer was fixed at a certain position, and the nozzle was fixed on the bracket. Adjust the position of the nozzle relative to the measurement line of the laser particle size analyzer. The starting position of the nozzle is 400mm directly above the middle position between the emission and receiving ends of the laser particle size analyzer. With the starting position of the nozzle as the coordinate origin, establish an X-Y plane Cartesian coordinate system . Since the atomization area...

Embodiment 3

[0041] In this example, on the basis of the pneumatic small particle size atomizing nozzle provided in Example 2, the hole diameter r of the liquid outlet at the end of the different liquid outlet pipelines, the end of the liquid outlet pipeline and the nozzle are tested in the same way. The effect of the distance d between the droplets on the atomization effect.

[0042] First of all, in order to detect the distance d between the end of the liquid outlet pipeline and the nozzle, and the cutting effect of the airflow on the sprayed liquid droplets, this embodiment provides a pneumatic small particle size atomizing nozzle, the main parameters of which are: the liquid outlet pipe The aperture r of the liquid outlet at the end of the road is 1mm, the inner diameter of the nozzle is 2mm, the output pressure of the liquid outlet pipeline is 1.2Mpa, the output pressure of high-pressure air is 2.5Mpa, and the slope angle α is 50°.

[0043] Adjust the distance d between the end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com