Two-time cutting process for front piece of western-style clothes

A front piece and process technology, applied in the field of suit making, can solve the problems of shrinking, different sizes of ready-to-wear, left-right asymmetry, etc., to achieve the effect of maintaining the size of ready-to-wear, uniform batch size, and solving uneven clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

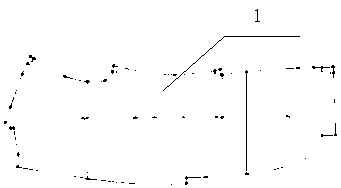

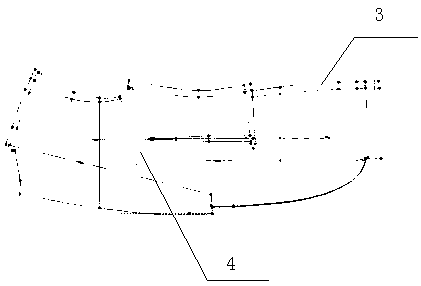

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Described, a kind of suit front sheet twice cutting process, this process comprises the following steps:

[0028] (1) Make the wool cutting sample 1 of the predecessor fabric according to the fine sample 5 of the front piece;

[0029] (2) Make the wool cutting sample 2 of the lining according to the fine lining sample;

[0030] (3) Make the wool cutting piece 3 of the predecessor fabric according to the wool cutting model 1 of the predecessor fabric;

[0031] (4) Cut the lining wool cutting piece 4 according to the wool cutting template 2 of the lining;

[0032] (5) Carry out interlining, with the reverse side of the wool cut piece 3 of the predecessor fabric facing up, and the piece lined with the rubber surface facing down, and set the upper shoulder seam, armhole, belly dart, and side seam according to the wool cut piece 3 of the front body fabric Blank lining cutouts and dart eyelets are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com