Power transformer vibration monitoring system based on wireless sensor network

A vibration monitoring system, power transformer technology, applied to vibration measurement, transmission system, digital transmission system in solids, etc., can solve the problems of complex cable layout, poor system flexibility, poor maintainability, etc., to achieve simple structure, autonomous High degree of chemical, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

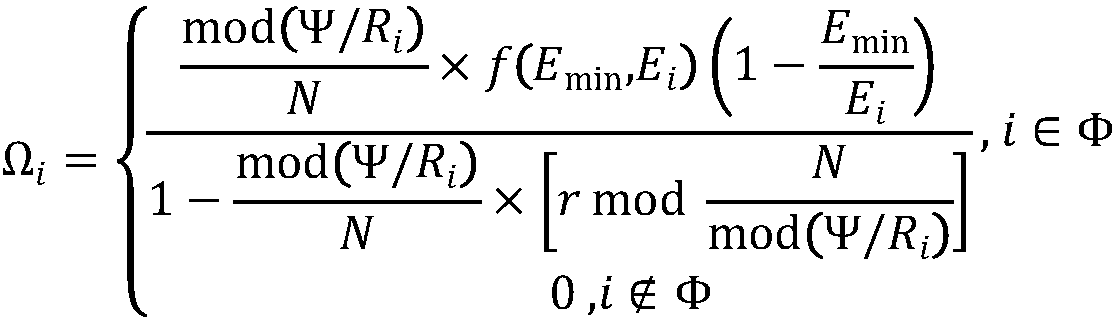

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described in conjunction with the following examples.

[0018] see figure 1 , this embodiment provides a wireless sensor network-based power transformer vibration monitoring system, including a sensor monitoring device 1 , a data receiving device 2 , and a power transformer vibration monitoring center 3 connected in sequence.

[0019] Among them, the sensing and monitoring device 1 is used to collect vibration data at each measuring point on the surface of the transformer. The sensor monitoring device 1 includes a converging node and a plurality of sensor nodes, the sensor nodes are used to collect and transmit vibration data; the converging node is used to collect the vibration data collected by the sensor nodes and forward the collected vibration data to the power transformer vibration monitoring center 3, Sensor nodes and sink nodes together constitute a wireless sensor network for transformer vibration monitoring, data collection an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com