A kind of electron beam bombardment furnace power supply and its regulated voltage equalization control method

A technology of electron beam bombardment and voltage equalization control, applied in electrical components, output power conversion devices, and structural components of conversion equipment, etc., can solve the problems of low reliability, high cost, and high requirements for device withstand voltage, and achieve fast performance, reduce withstand voltage requirements and costs, and ensure the effect of insulation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

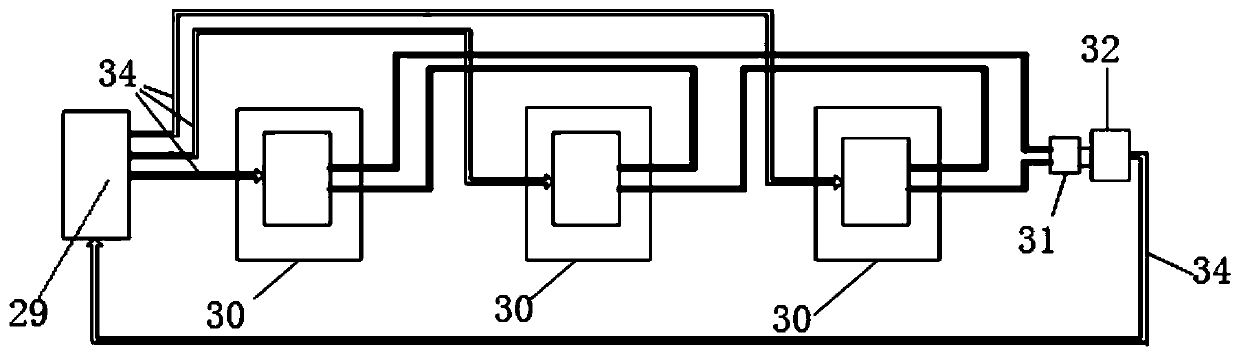

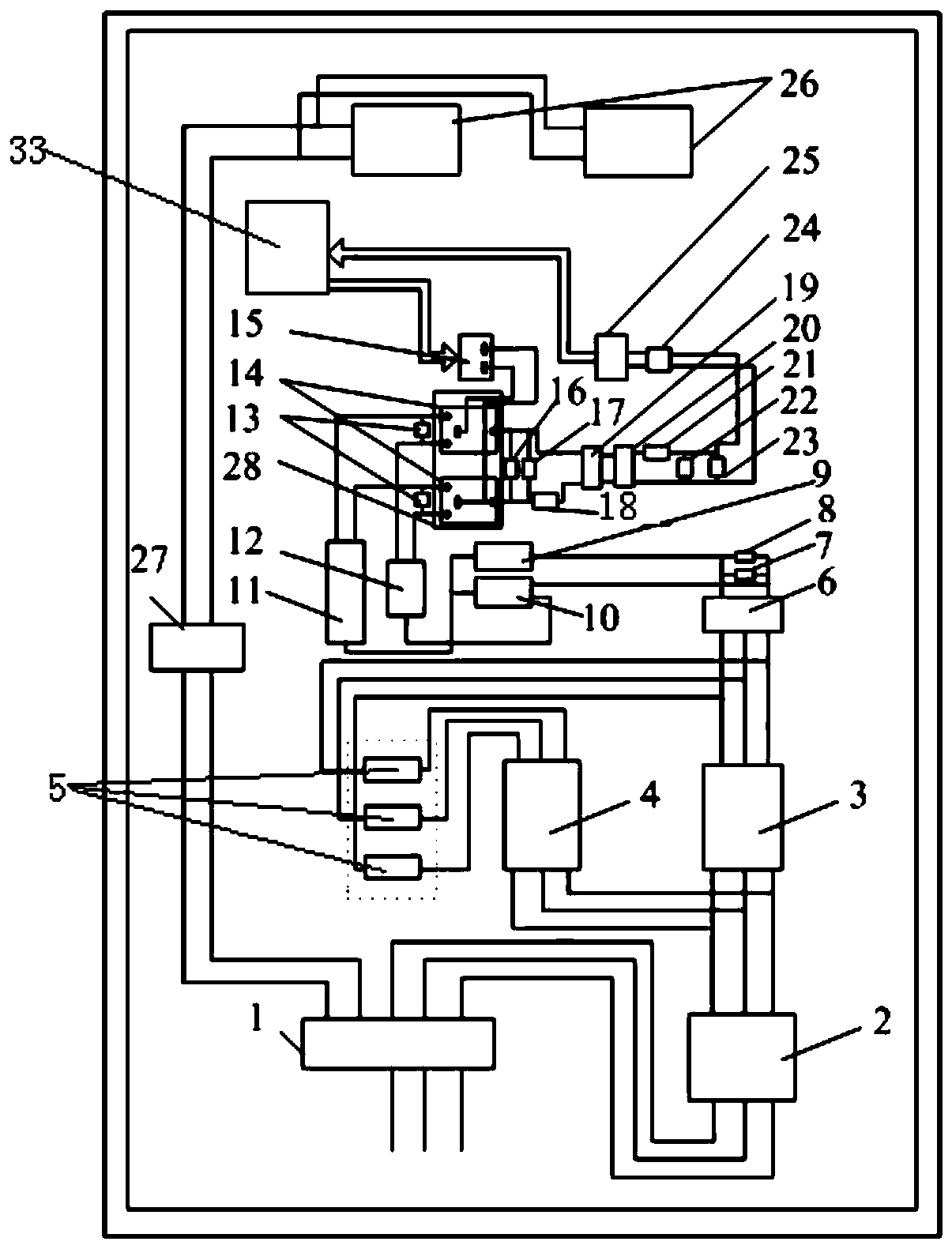

[0027] The present invention is an electron beam bombardment furnace power supply, the structure of which is as follows: figure 1 As shown, including the control cabinet A29, the control cabinet A29 is connected to at least three power cabinets 30 in turn, and each power cabinet 30 is connected to the control cabinet A29 separately. Among the power cabinets 30 connected in sequence, the power cabinet 30 at the head end Both the voltage hall sensor B31 and the power supply cabinet 30 located at the end are connected, and the voltage hall sensor B31 is also connected to the total voltage feedback DSP board 32, and the total voltage feedback DSP board 32 is also connected to the control cabinet A29.

[0028] Each power supply cabinet 30 and the total voltage feedback DSP board 32 are connected to the control cabinet A29 through an optical fiber 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com