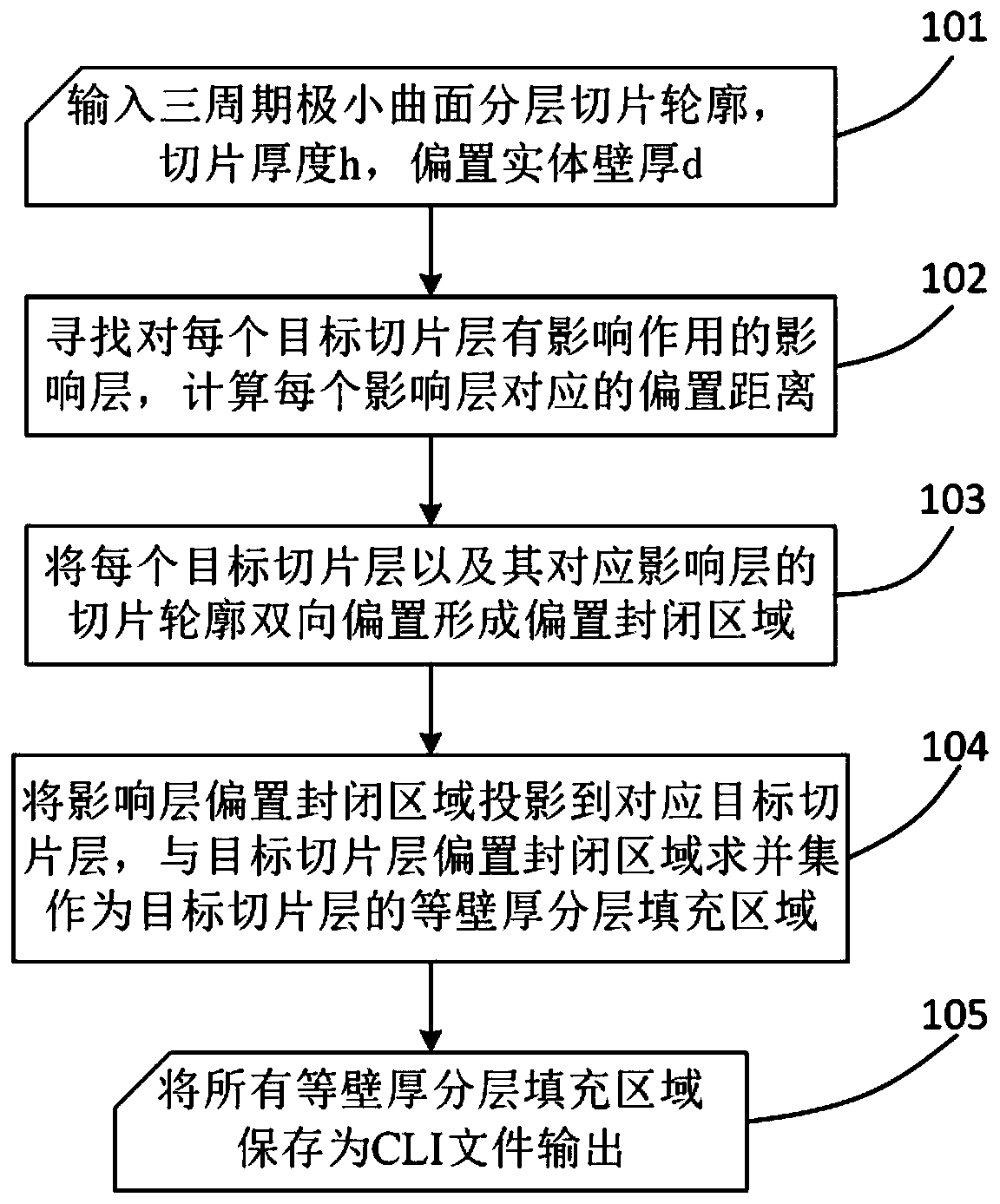

A Method for Generation of Three-Period Minimalist Curved Surfaces with Equal Wall Thickness Layered Filling Regions

A technique of layered filling with extremely small surfaces, applied in the directions of instrumentation, computing, and 3D image processing, etc., can solve problems such as many defects and complex generation process of layered filling areas, and achieve time-consuming, accurate and reliable layered filling areas , The method is accurate, stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

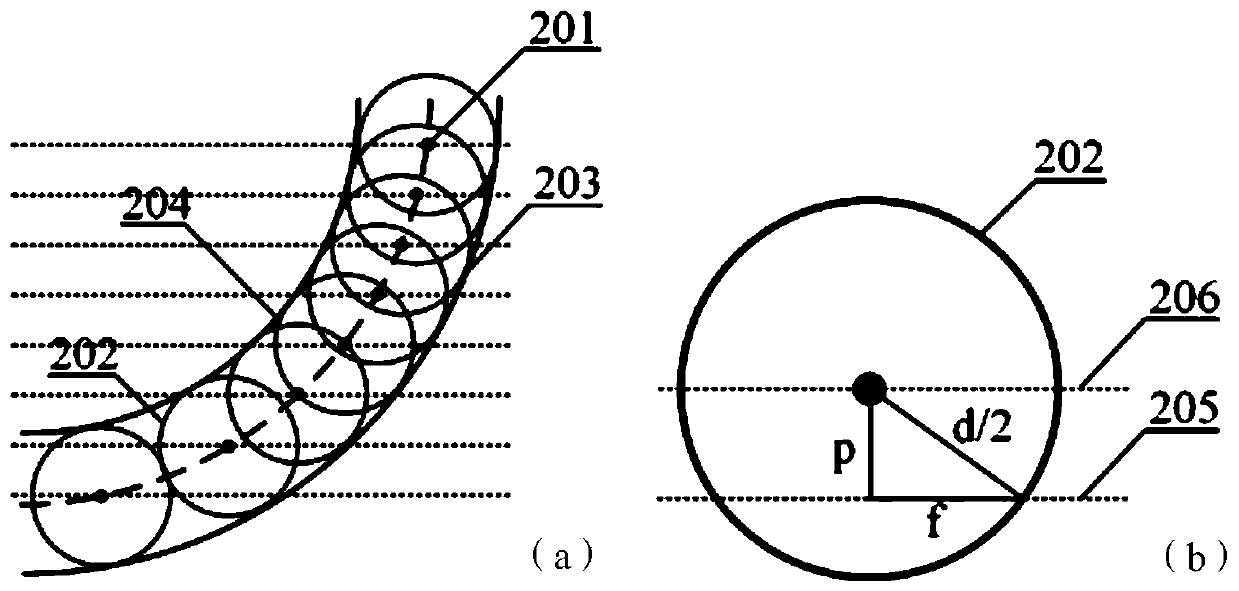

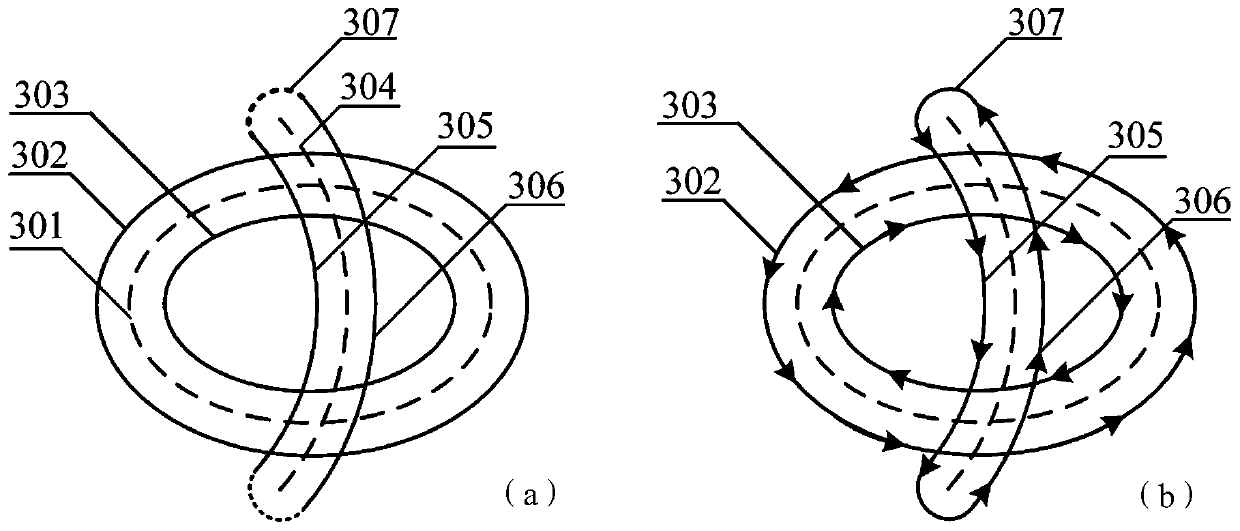

Method used

Image

Examples

Embodiment 1

[0059] Select the three-period minimal surface P surface, the surface slice profile includes two slice profiles of closed profile and open profile, slice thickness h=0.1mm, input the P surface slice profile as Figure 5 As shown, among them, Figure 5 (a) is the left view of the P surface slice profile, Figure 5 (b) is a three-dimensional view of the slice profile of the P surface, and the offset solid wall thickness is set to d=0.5mm.

[0060] Figure 6 The generation results of the layered filling area with equal wall thickness on the P surface of Example 1 are shown. It can be clearly seen that this method can be compatible with closed contours and open contours, and can generate reliable and accurate layered filling areas.

Embodiment 2

[0062] Select the three-period minimal surface G surface, the surface slice profile only contains the open profile, slice thickness h = 0.1mm, input the G surface slice profile as Figure 7 As shown, among them, Figure 7 (a) is the left view of the G surface slice profile, Figure 7 (b) is a three-dimensional view of the contour of the G curved surface slice, and the offset solid wall thickness is set to d=0.5mm.

[0063] Figure 8 It shows the generation result of the layered filling area with equal wall thickness on the G curved surface in Example 2. The inventive method is used to quickly generate the layered filling area with complex topological structure, and the output result is saved as a CLI file for 3D printing equipment manufacturing. The three-period minimum of equal wall thickness Curved surface structure, the whole process is fast and reliable, avoiding the shortcomings of traditional methods based on three-dimensional space offset.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com