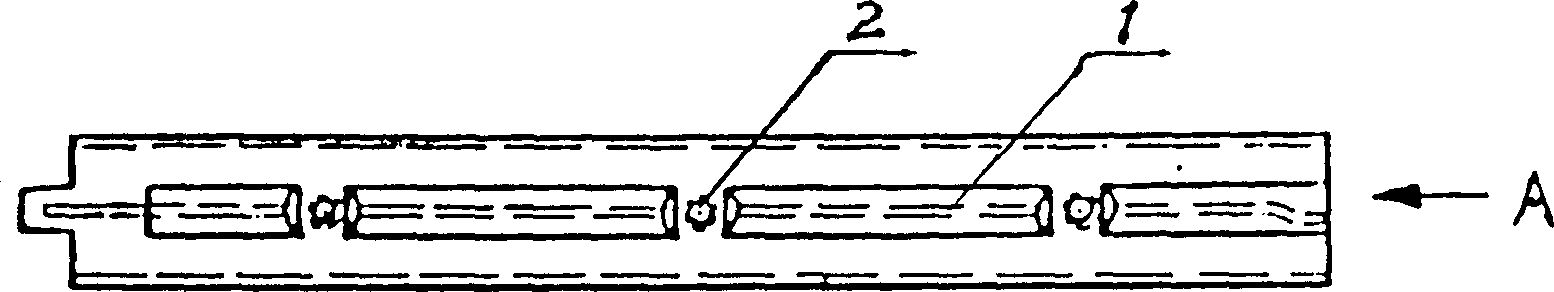

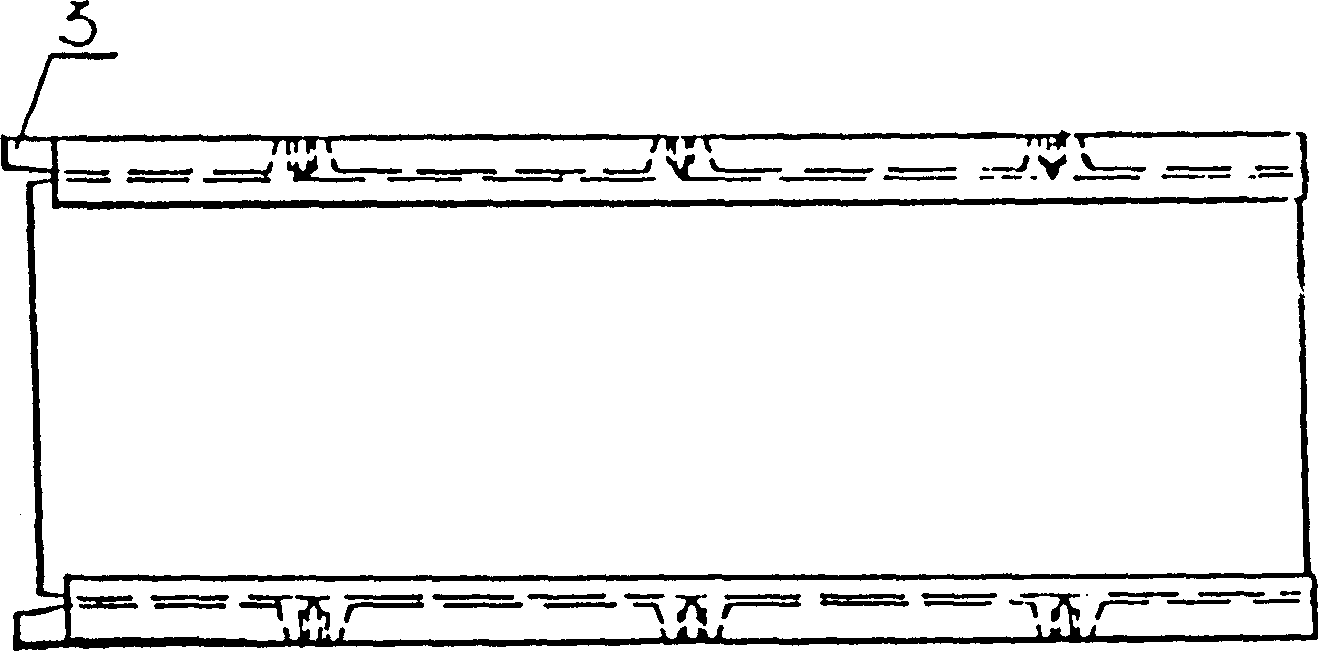

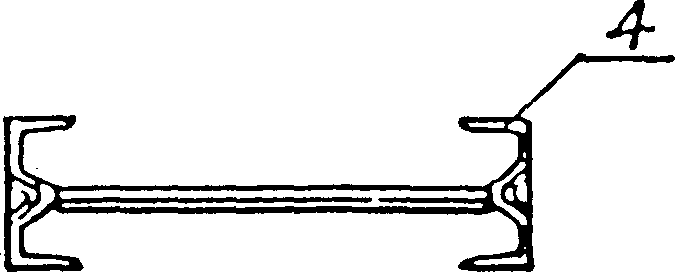

Middle trough for chain plate conveyor and its manufacture

A technology of conveyors and chain plates, applied in conveyors, transportation and packaging, etc., can solve the problems of high manufacturing cost, short service life, and poor wear resistance of the middle groove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] 36kg of caprolactam monomer is in a closed container, heated to 69°C under normal pressure to be molten, continue to heat to 140°C, vacuumize at 1.333kpa for 15 minutes, add 4Og of solid sodium hydroxide, 1.8kg of red phosphorus, 1.8 kgMgO, 14g carbon black, stir evenly, evacuate for 30 minutes at a vacuum degree of 1.333kpa, add 370ml of triphenylmethane triisocyanate, mix it evenly as soon as possible, cast it into the inner wall within 1 minute, coat it with silicone oil and heat to In a mold at 170°C, keep warm in an oven for 20 minutes. After polymerization, take it out from the mold to obtain the required middle groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com