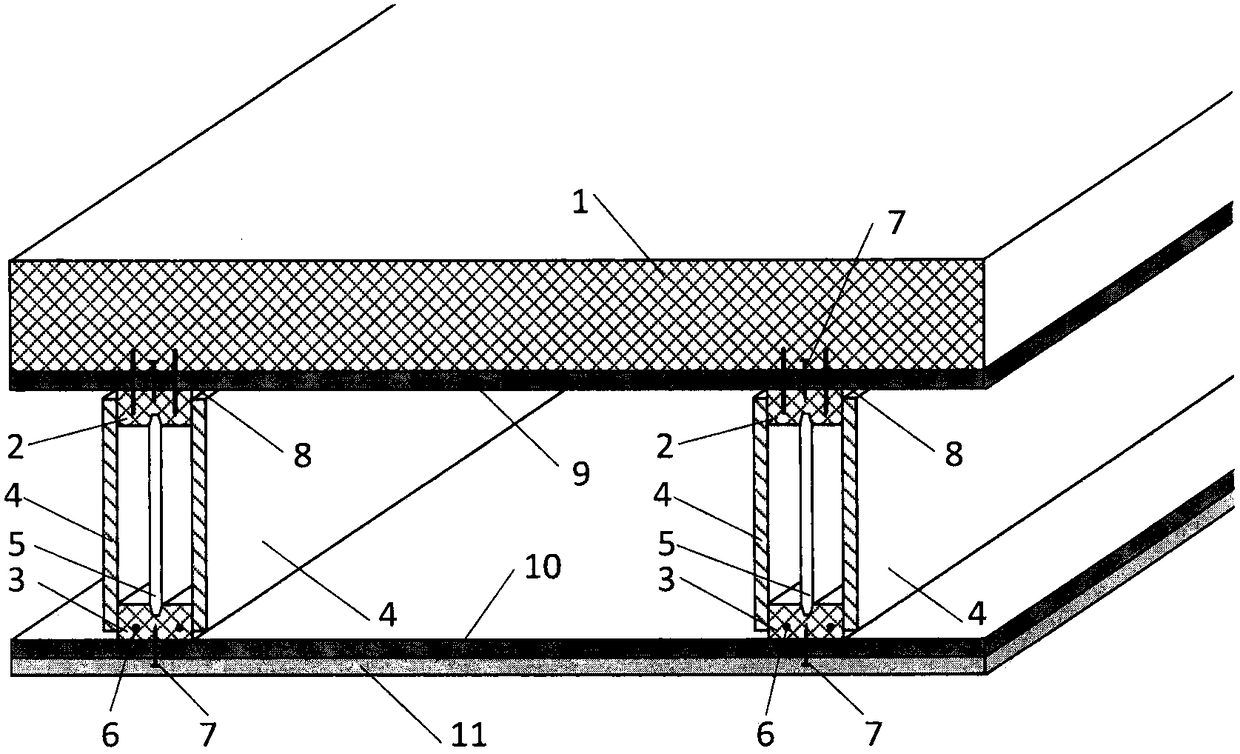

Lightweight aggregate concrete-bamboo integrated material composite floor system

A technology of lightweight aggregate concrete and glulam, applied in floors, building components, buildings, etc., can solve problems such as poor deformation performance, low bearing capacity, and poor ductility, and achieve good fire resistance, large bearing capacity, and good ductility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

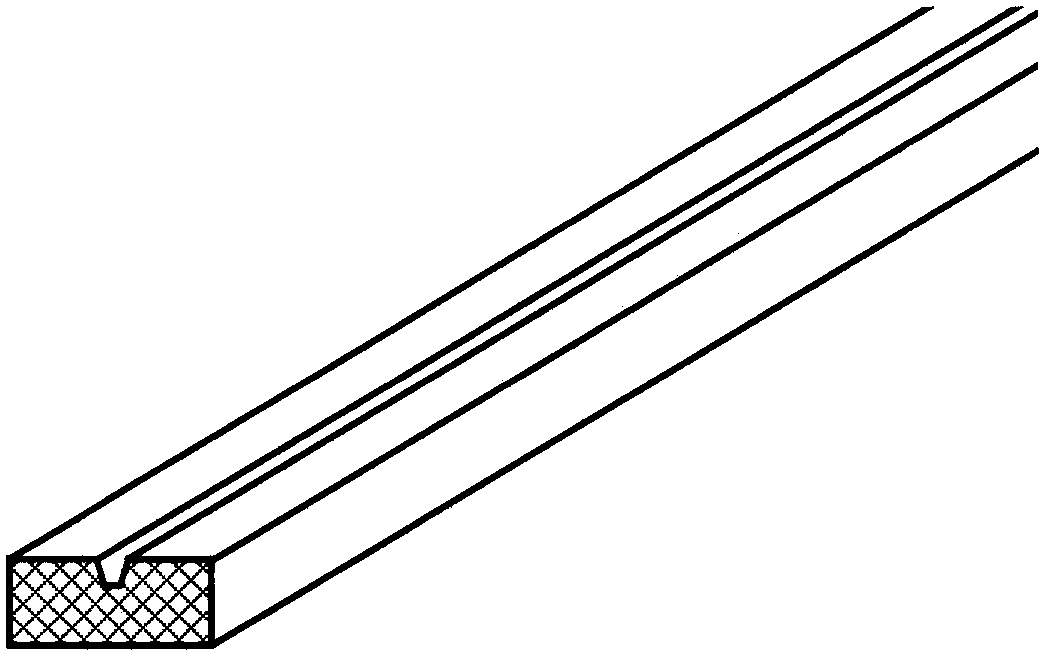

[0033]Example 1: Take 9.5mm thick, 290mm high bamboo curtain plywood as the side web, 9.5mm thick, 250mm high bamboo curtain plywood as the middle web, take 40mm high, 80mm wide bamboo lamella as flanges, steel bars are The side web and the flange are bonded with adhesive, the middle web and the upper and lower flanges are tenoned and bonded with adhesive, the concrete slab thickness is 100mm, the shear key spacing is 100mm, the floor slab thickness is 12mm, the ceiling slab The thickness of gypsum board is 9.5mm. The box girder is 300mm high and 3660mm long.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com