Flat plastic formwork for construction

A technology for plastic formwork and construction. It is applied in the direction of construction, building structure, and on-site preparation of building components. It can solve the problems of formwork scrapping and other issues, and achieve the effects of reducing the thickness of the plate surface, ensuring tight fit, and increasing the number of turnovers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

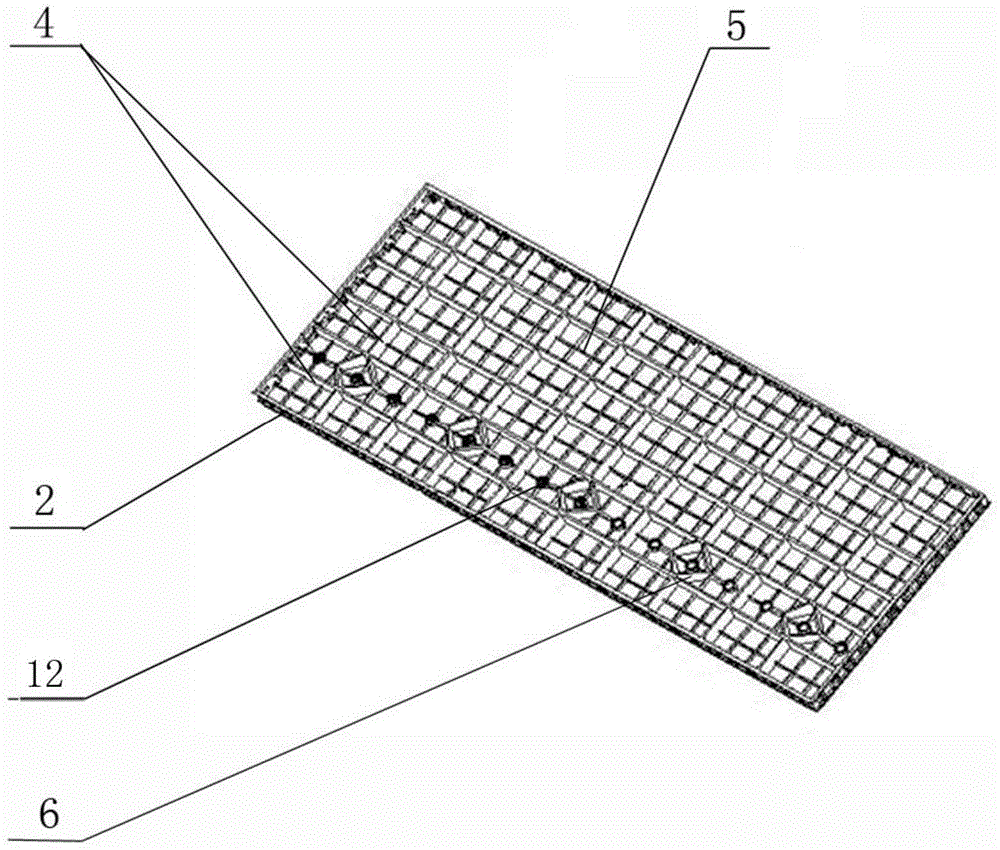

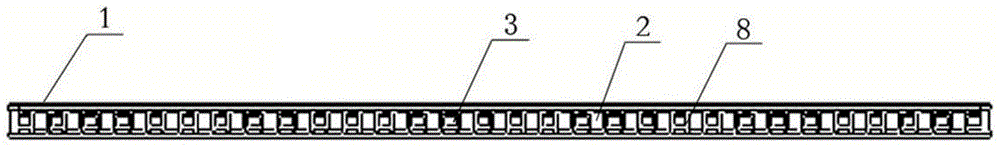

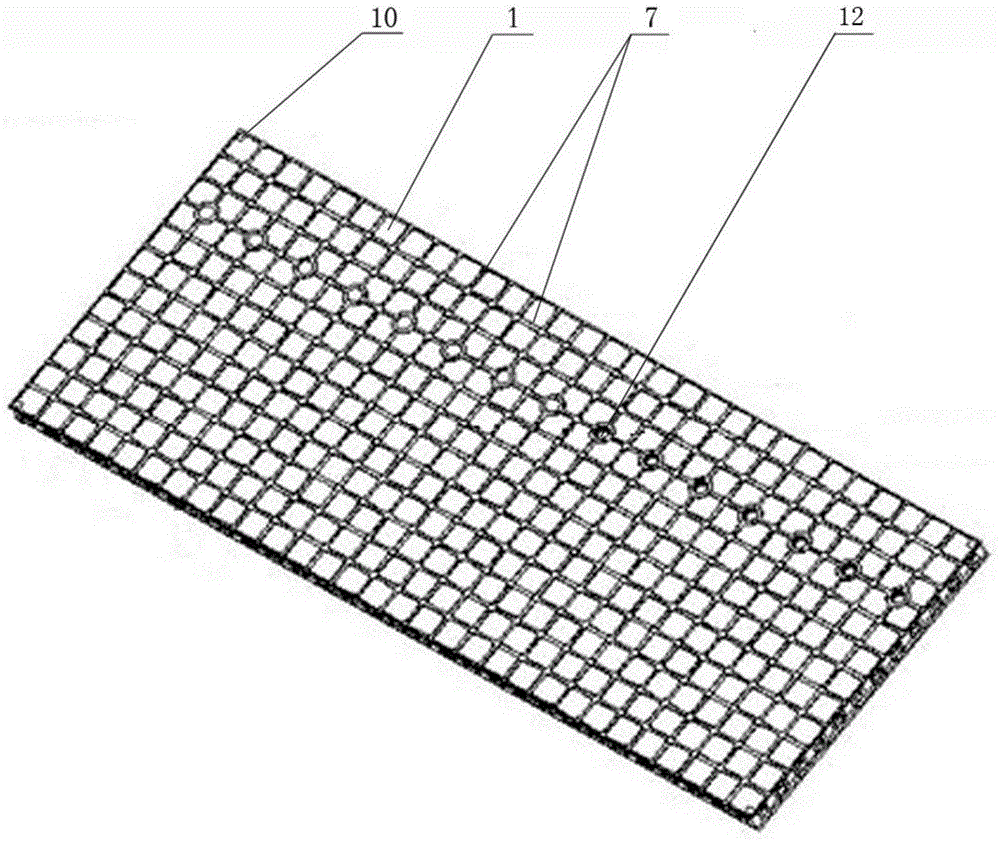

[0021] Such as Figure 1 ~ Figure 3 Shown, the panel among the present invention is rectangular panel 1, is provided with frame 2 perpendicular to panel 1 board surface around panel 1 back side, frame 2 is a plate-like body, has some and other formwork connection usefulness on frame 2. The connecting holes 3 are rectangular through holes, and all the connecting holes 3 on the frame 2 on each side of the panel 1 are arranged in a straight line parallel to the long side of the frame 2 where they are located. A back rib is vertically arranged on the back of the panel 1, and the back rib is a plate-shaped body. The back rib is a keel supporting the panel 1 and is used to enhance the bending resistance of the panel 1. The back rib in the present invention includes a main rib 4 and a secondary rib 5, the upper edge of the main rib 4 reaches or approaches the plane where the top surface of the frame 2 is located, and the upper edge of the main rib in the present invention is in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com