Square tube support steel silo

A technology of tube support and steel silo, applied in the field of shear wall and square tube support steel silo, can solve the problems of out-of-plane bulging, steel waste, low out-of-plane rigidity, etc., to increase out-of-plane rigidity, reduce construction costs, Guaranteed compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

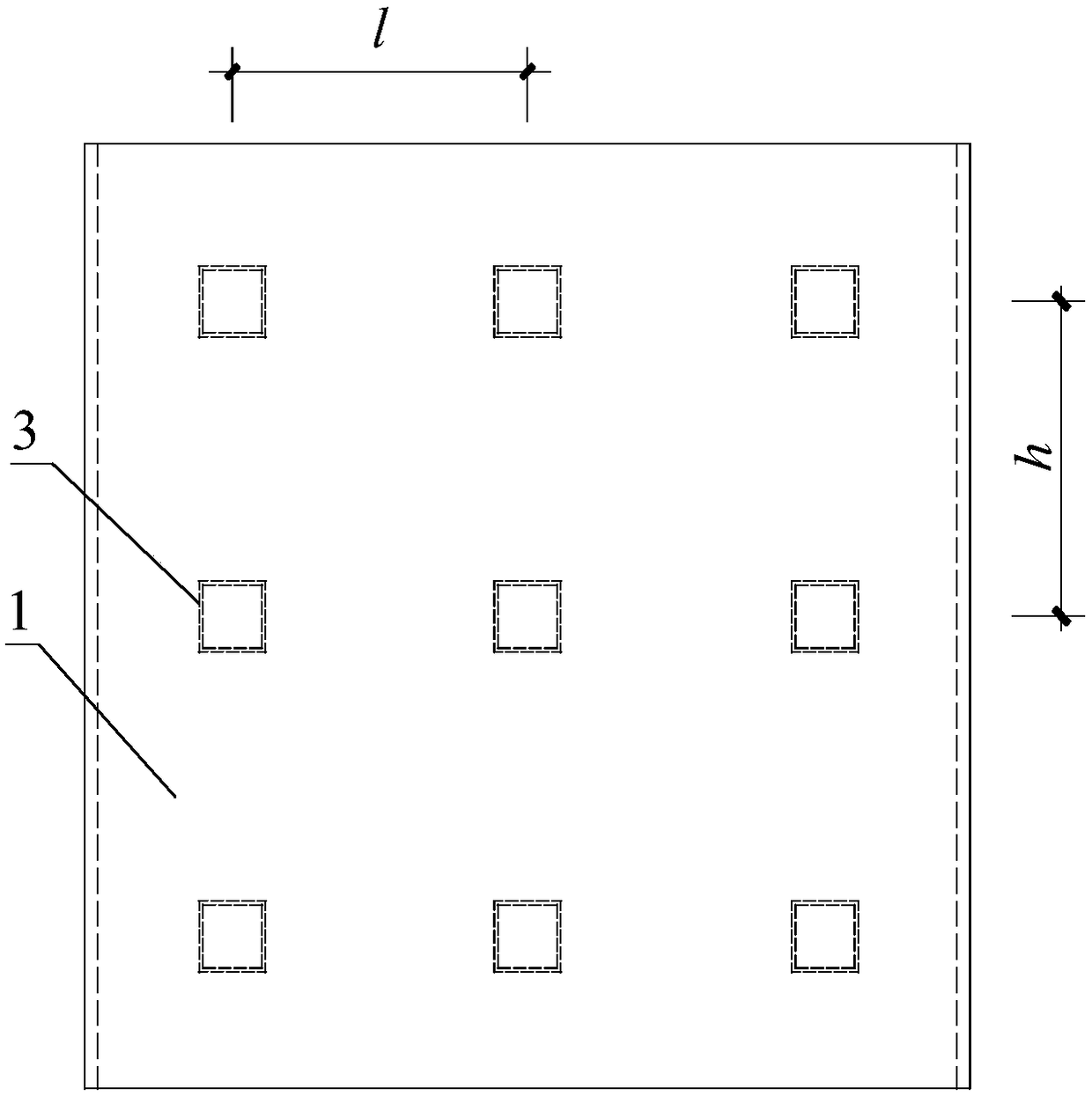

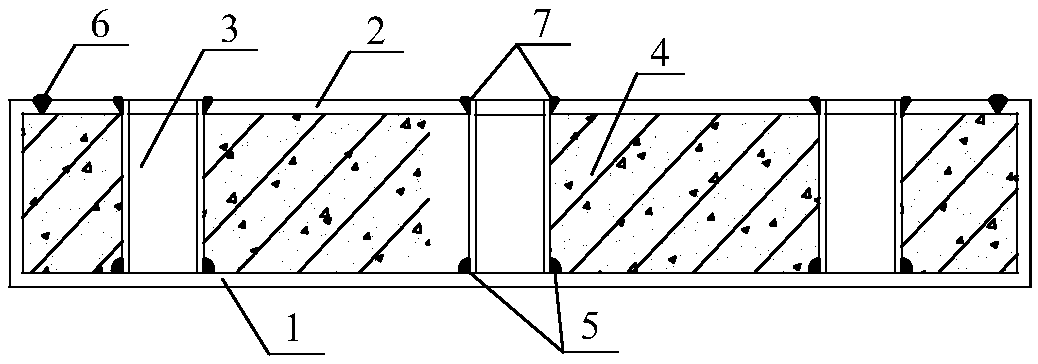

[0012] A steel silo supported by a square tube, consisting of a steel plate 1, a steel plate 2, and a square tube support 3 as a basic unit, the two sides of the basic unit are respectively a steel plate 1 and a steel plate 2, wherein the steel plate 1 is bent into a crimped groove shape by cold working , the thickness t of the two steel plates is 2mm-3mm, the steel plate 1 is connected to the square tube support 3 through the weld 5, the side length of the square tube support 3 is 30mm-50mm, and the thickness is 3mm, the adjacent square tube support 3 The horizontal and vertical distances are both (200-300)t, and a square hole is left at the position corresponding to the steel plate 2 and the square tube support 3; The pipe support 3 and the steel plate 2 are connected through the weld 7; the concrete 4 is poured in the empty warehouse formed by the steel plate 1 and the steel plate 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com