A kind of magnetron sputtering optical coating equipment and coating method

A magnetron sputtering and optical coating technology, applied in sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve the problems of less coating, not suitable for large-scale production, and low efficiency of target coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Several magnetron sputtering optical coating devices and magnetron sputtering optical coating methods involved in the present invention are described in conjunction with the accompanying drawings.

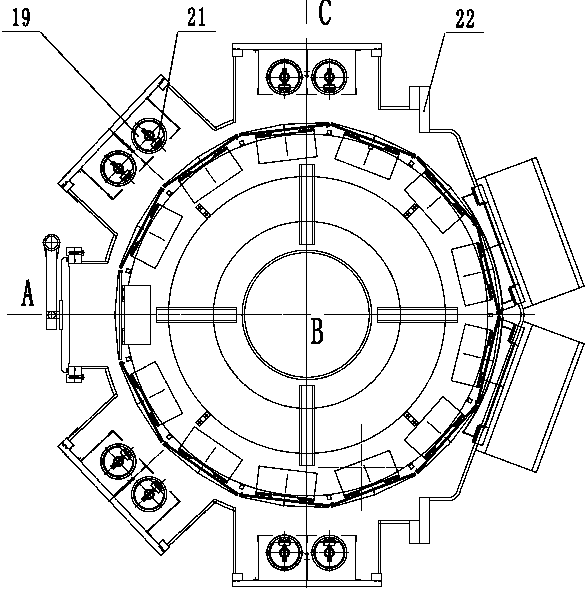

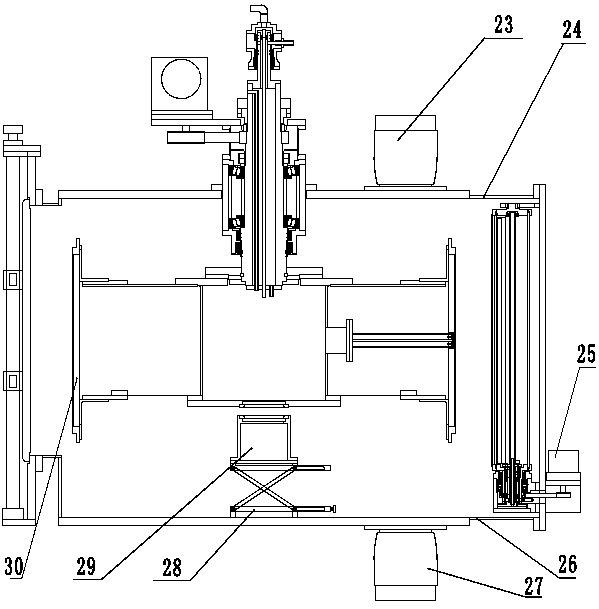

[0030] Such as Figures 1 to 3 As shown, a magnetron sputtering optical coating equipment includes a vacuum coating chamber 3, a magnetron sputtering target assembly 19, and a vertical rotating drum 1; the vacuum coating chamber 3 is a vertical cylindrical structure, and the upper and lower ends are provided with The upper cover plate 24 and the lower cover plate 26 have a side door 22 on the side; the vertical rotary drum 1 is located in the vacuum coating chamber 3 and rotates around the vertical axis. The base plate 30, the center of the vertical rotating drum 1 is provided with a rotary sealing box 10, the top of the rotary sealing box 10 is connected with a rotating shaft 5, and the rotating shaft 5 is supported on the upper cover plate 24 of the vacuum coating chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com