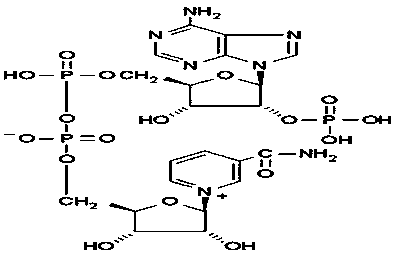

Production method of oxidized nicotinamide adenine dinucleotide phosphate

A nicotinamide adenine, dinucleotide technology, applied in chemical instruments and methods, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of low content, complicated procedures, low product yield, etc. Simple process, minimized product use cost and high separation purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Propagate with Bacillus megaterium or Bacillus subtilis, insert 5% of the inoculum into 30L of TB medium sterilized at 121°C for 20 minutes, use ammonia water to control pH7.0 throughout the process; initial speed 300 rpm Minutes, 600 rpm in the middle and late stages; initial flow rate 1:0.6, 1:1.2 in the middle and late stages; tank pressure 0.05MPa; after the dissolved oxygen rebounds, start to add 80% glycerin solution at a rate of 165ml / h; when OD600 ≥ 60 , the temperature was lowered from 37°C to 30°C, and the culture period was 42h. The OD600 of the tank is 98, and the volume of the tank is 34.2L.

[0033] (2) The NADP+ content of the fermentation broth was detected by HPLC to be 256mg / L.

[0034] (3) The fermentation broth was centrifuged at 8000 rpm to collect 6.82kg of bacterial cells.

[0035] (4) The bacteria were resuspended in 24L of deionized water, and homogeneously crushed twice under 60MPa pressure.

[0036] (5) Add 6.4g of chitosan to the crush...

Embodiment 2

[0039] (1) Product I in Example 1 was concentrated to 1.46L with a 300-600Da nanofiltration membrane.

[0040](2) Add 50g of strong acid cationic resin to the concentrated solution, the resin is Na+ type, adjust the pH to 2.8-3.0 with hydrochloric acid, stir for 0.5-4h, and adjust the pH at any time to keep it within the range of 2.8-3.0.

[0041] (3) Filtrate, collect 1.42L of filtrate, lower the pH to 1.5.0-2.0 with hydrochloric acid, put on a weakly acidic cationic resin column Φ35*350, the resin loading capacity is 150ml, the resin is pre-transformed into H+ type, and the sample loading flow rate is 2BV / h; After loading the column, rinse with 2BV deionized water.

[0042] (4) Desorb with 0.2M sodium hydroxide solution, and intercept 345ml of the intermediate desorption solution according to the detection index.

[0043] (5) The desorption liquid is adjusted to PH6.5 with hydrochloric acid, and the above-mentioned desorption liquid is desalted and concentrated with a nanof...

Embodiment 3

[0045] (1) Add 300ml of acetone dropwise to the product II in step (5) of Example 2 for 0.5h.

[0046] (2) After the dropwise addition, crystallize at -5--5°C for 6 hours.

[0047] (3) Vacuum filter with a Buchner funnel, top wash with 50ml of acetone, and collect the solid.

[0048] (4) The solid was vacuum-dried at ≤50°C for 4 hours to obtain 6.86 g of solid, namely product III. The content of NADP+ sodium salt was detected by HPLC to be 99.4%. Yield 88.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com