Preparation method and production device of thioacetic acid

A technology for thioacetic acid and production equipment, applied in chemical instruments and methods, organic chemistry, phosphorus compounds, etc., can solve problems such as complex production equipment, unsatisfactory yield and purity of thioacetic acid, and difficult control of the reaction process , to achieve high economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

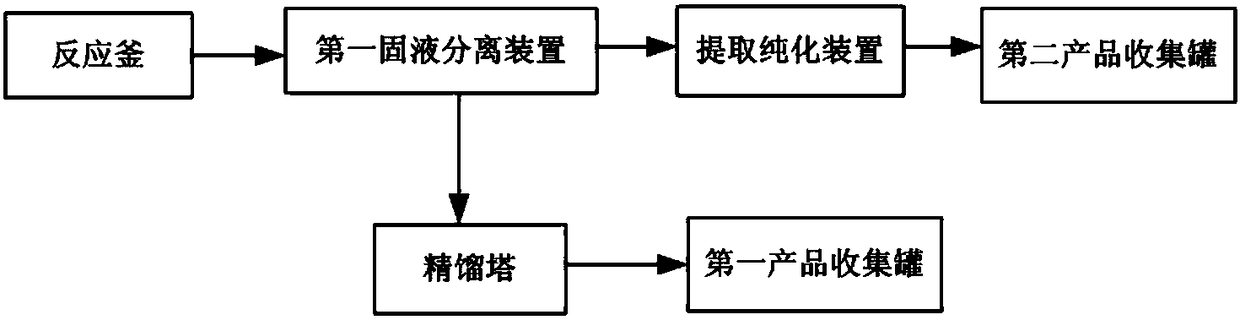

[0064] The invention provides a kind of preparation method of thioacetic acid, comprising:

[0065] A) Mix the acetic acid solution, phosphorus pentasulfide and the catalyst to obtain a mixed solution after the reaction; the temperature of the reaction is not higher than 50° C., the pressure of the reaction is -0.1 to 0.5 MPa, and the reaction time is 1 to 12 hours;

[0066] The catalyst is selected from one or more of low molecular alcohol, acid solution and water;

[0067] B) The mixed solution is subjected to solid-liquid separation for the first time, and the obtained liquid phase substance is rectified to obtain thioacetic acid.

[0068] In the invention, the acetic acid solution, the phosphorus pentasulfide and the catalyst are firstly mixed, and the mixed solution is obtained after the reaction.

[0069] The present invention has no special limitation on the preparation method of the acetic acid solution, and the preparation method of the solution well known to those s...

Embodiment 1

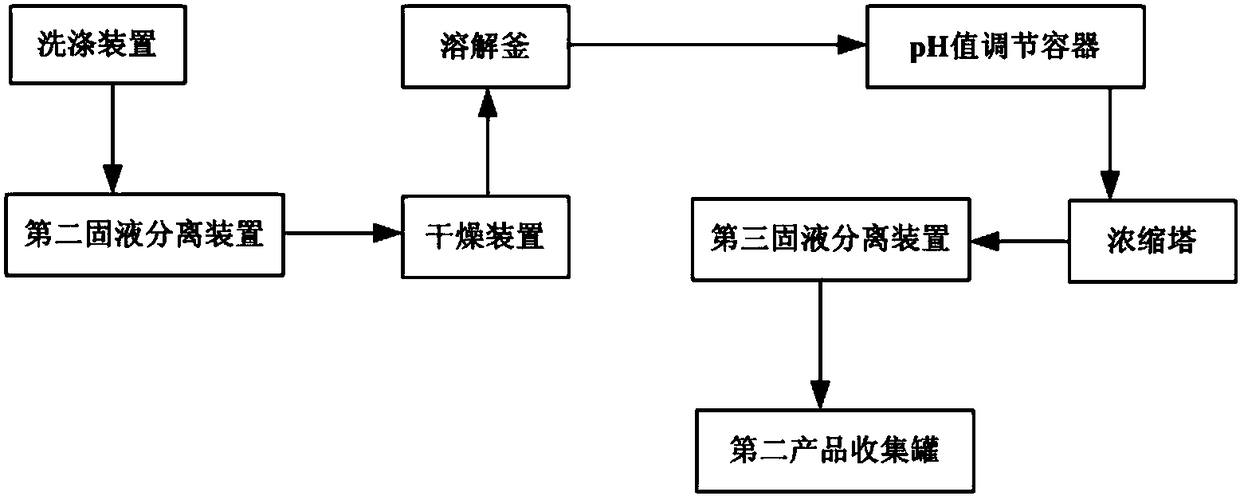

[0156] Mix 1000 g of fresh acetic acid solution with a content of 95 wt %, 400 g of flaky phosphorus pentasulfide from which metal impurities have been removed, and 20 g of aqueous methanol solution with a mass fraction of 95 wt %, and react in a reactor at 45 ° C and normal pressure for 3 to 5 hours to obtain a mixed solution. The mixed solution is carried out solid-liquid separation for the first time in the first filter, and the obtained liquid phase material is carried out rectification for the first time in the first rectification tower, and the tower bottom temperature of the rectification for the first time is The temperature at the top of the first rectification is 115.5°C, the pressure of the first rectification is -0.05MPa, the time of the first rectification is 30min, and the light components with a boiling point of 60-119°C are obtained . The heavy component obtained after the first rectification is mixed with water according to the mass ratio of 65:1, hydrolyzed ...

Embodiment 2

[0159] Mix 400 g of fresh acetic acid solution with a content of 95 wt%, 600 g of rectified acetic acid solution for reuse, 400 g of flaky phosphorus pentasulfide for removal of metal impurities, and 20 g of ethylene glycol, and react in a reaction kettle at 35° C. under normal pressure for 3 to 5h, a mixed solution was obtained. The mixed solution is carried out solid-liquid separation for the first time in the first filter, and the obtained liquid phase material is carried out rectification for the first time in the first rectification tower, and the tower bottom temperature of the rectification for the first time is The temperature at the top of the first rectification is 115°C, the pressure of the first rectification is -0.05MPa, the time of the first rectification is 30min, and the light components with a boiling point of 60-119°C are obtained . The heavy component obtained after the first rectification is mixed with water according to the mass ratio of 65:1, hydrolyzed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com