Low-alkality Portland cement clinker and preparation method thereof

A Portland cement and clinker technology, which is applied in cement production and other directions, can solve the problem that the grindability and scorchability are difficult to ensure, and the low-alkali Portland cement clinker is difficult to achieve continuous production, grindability and ease of use. The problem of high content of sintered siliceous materials can achieve the effect of good calcination effect, increased compressive strength and low alkali content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Using the preparation method of low-alkali Portland cement clinker, produce low-alkali Portland cement clinker on the new dry process production line of 2500t clinker / d. The control range of the three rate values of the clinker is: saturation ratio KH=0.930± 0.020, silicic acid SM=2.65±0.10, aluminum rate IM=1.40±0.10. The specific operation steps are:

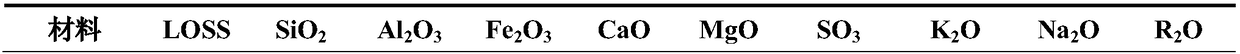

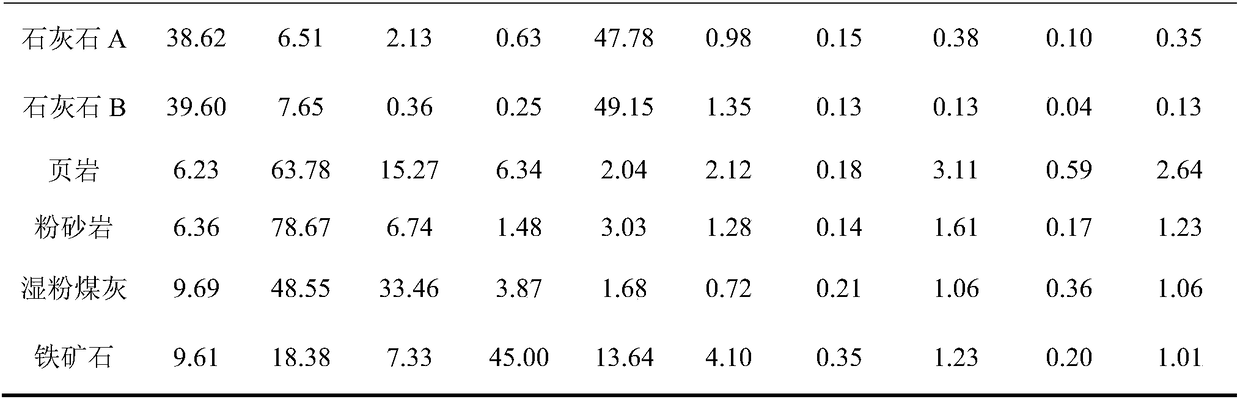

[0028] 1) Determine the range of limestone mix ratio: according to the chemical composition of different grades of limestone A and limestone B, iron ore, shale, wet fly ash and siltstone, as well as the calorific value, ash content, ash chemical composition and The unit heat consumption value of kiln clinker production is 3429kJ / kg, and the alkali content R 2 O≤0.60wt%, and siltstone with poor grindability and burnability, the wet basis ratio in the raw meal is ≤3.0wt%;

[0029] 2) Raw material pretreatment: crush or sieve limestone, iron ore, shale, wet fly ash and siltstone, and mix and pre-homogenize limestone of...

Embodiment 2

[0061] Using the preparation method of low-alkali Portland cement clinker, produce low-alkali Portland cement clinker on the new dry process production line of 4800t clinker / d. The control range of the three rate values of the clinker is: saturation ratio KH=0.930± 0.020, silicic acid SM=2.65±0.10, aluminum ratio IM=1.40±0.10. The specific operation steps are:

[0062] 1) Determine the range of limestone mix ratio: according to the chemical composition of different grades of limestone A and limestone B, iron ore, shale, wet fly ash and siltstone, as well as the calorific value, ash content, ash chemical composition and The unit heat consumption value of clinker production in the kiln is 3136kJ / kg, and the alkali content R 2 O≤0.60wt%, and siltstone with poor grindability and burnability, the wet basis ratio in the raw meal is ≤3.0wt%;

[0063] 2) Raw material pretreatment: Limestone, iron ore, shale, wet fly ash and siltstone are crushed or sieved, and different grades of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com