Production line of gas mask assembly

A gas mask and production line technology, applied to household appliances, other household appliances, household components, etc., can solve problems such as large differences in quality consistency, backward automation level of gas mask assembly, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

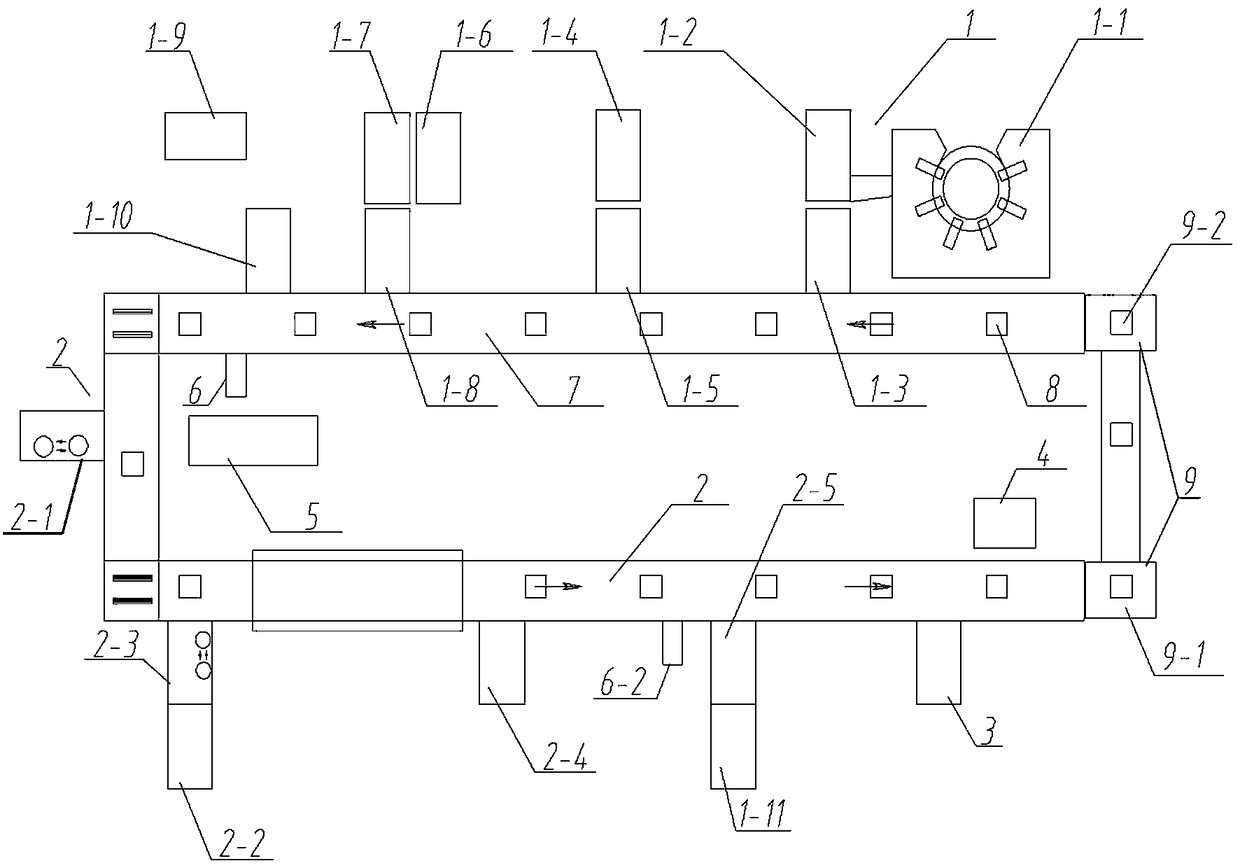

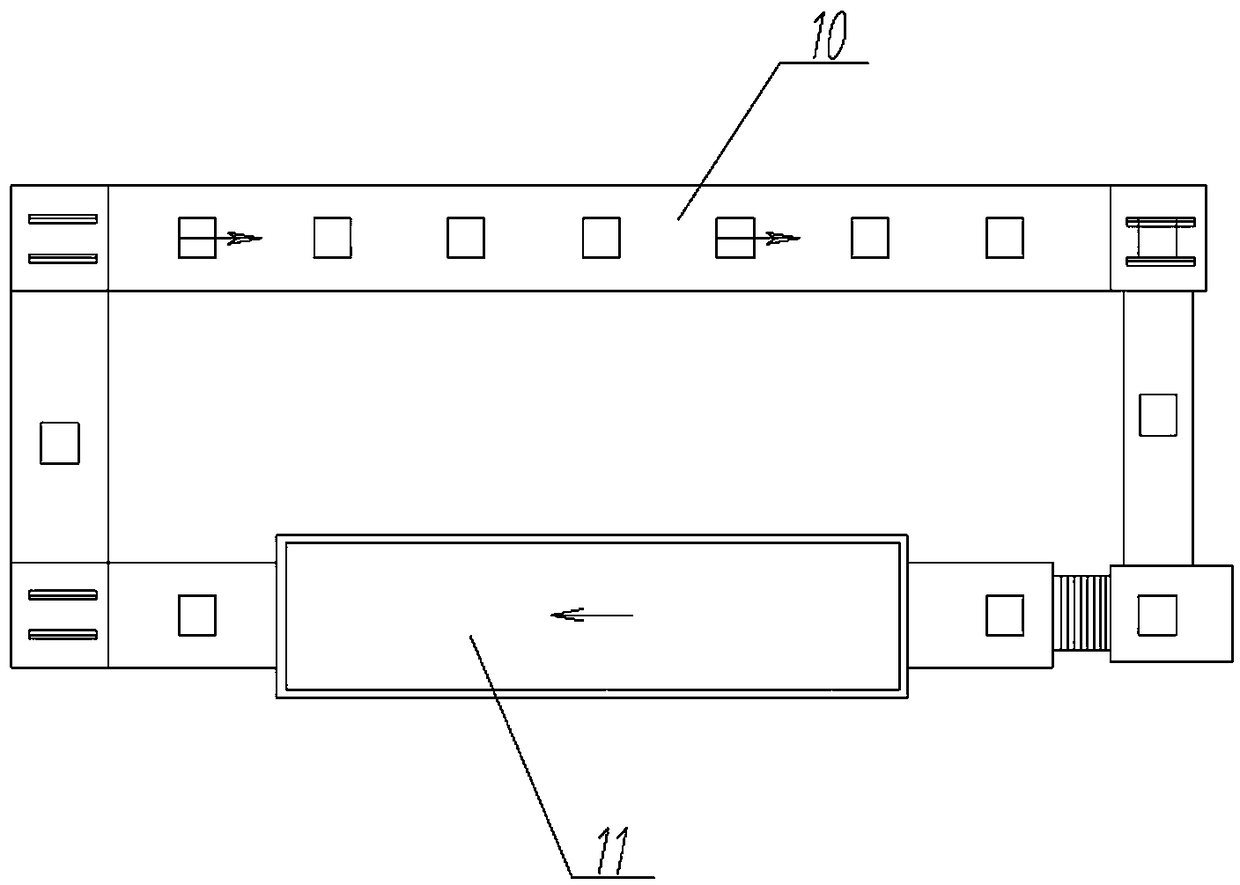

[0019] Such as figure 1 and 2 The production line of the general assembly of the gas mask shown includes the main control cabinet 5, the assembly station 1, the inspection station 2, the inspection station 3, the industrial computer 4, the inkjet printer 6, the conveying line body 7, the pallet 8, the material loading worker Station 10, packaging station 11 and compressed air pipelines, connecting cables, servo motors, cylinders, and manual buttons, which include loading station 10, which is connected to assembly station 1 through material conveying device 9, The assembly station is connected to the inspection station, and the inspection station 3 is connected to the packaging station 11 through a material conveying device.

[0020] The assembly station 1 is composed of a communication membrane assembly station 1-1, a communication membrane assembly inspection station 1-2, a water blocking cover assembly station 1-3, a secondary intercom inspection station 1-4, and a tank joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com