Lower disc transmission mechanism of grinder or polisher

A technology of transmission mechanism and polishing machine, which is applied in the directions of grinding machine parts, grinding/polishing equipment, grinding feed motion, etc. Long and other problems, to achieve the effect of good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

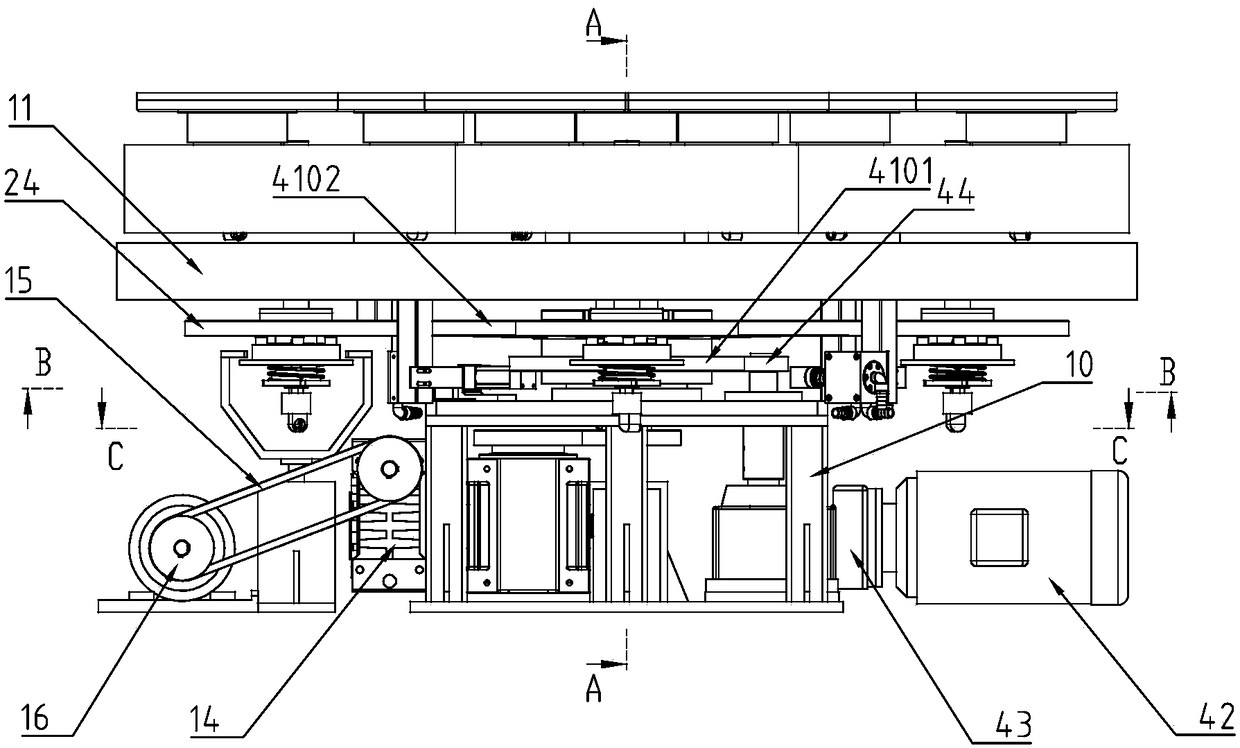

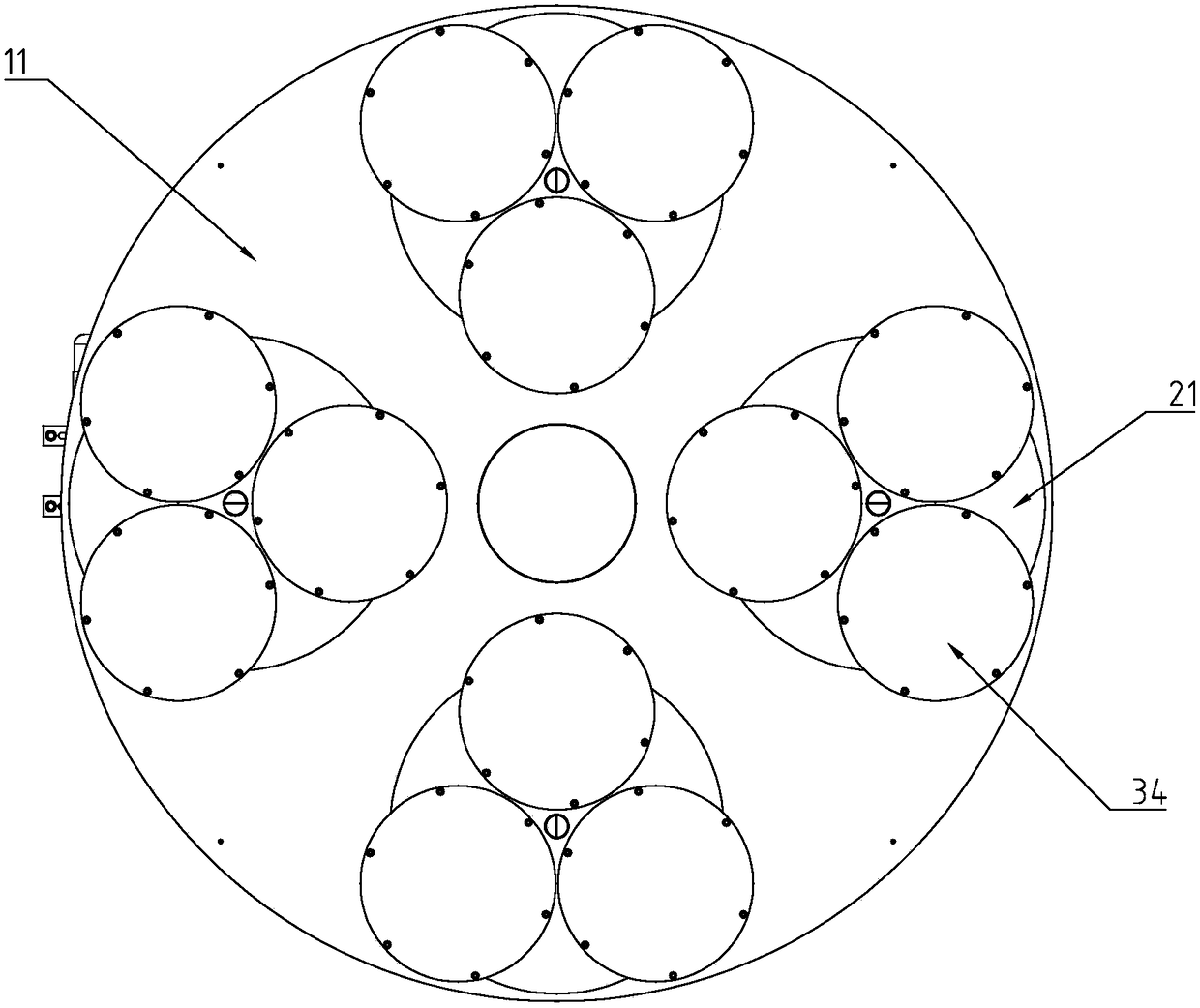

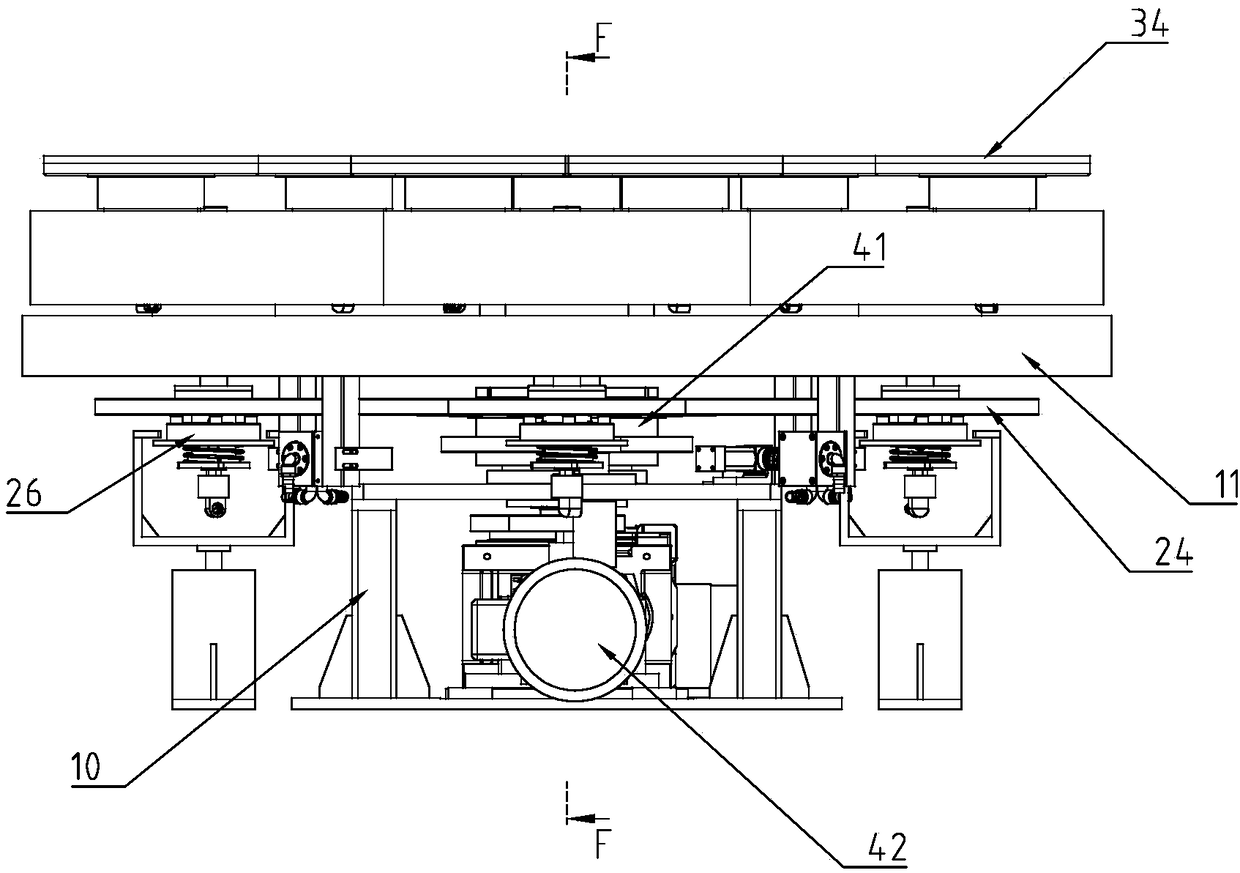

[0037] The lower plate transmission mechanism of the polishing machine in embodiment 1 of the present invention is as follows: Figure 1 to Figure 10 Shown, comprise frame 10, 4 lower disk assemblies, lower disk revolution mechanism and lower disk rotation mechanism.

[0038] The lower plate revolution mechanism includes a main tray 11, a main shaft 12, a bearing seat 13, a final reducer 14, a belt drive 15, a main motor 16, a main shaft gear 17, a divider 18, a divider gear 19 and 4 clutch mechanism driving devices.

[0039] Bearing block 13 is fixed on frame 10 middle parts. The main shaft 12 is vertically installed in the bearing housing 13 and supported by the bearing 1301 . The main tray 11 is fixed on the upper end of the main shaft 12, and the main tray 11 has four supporting holes 1101 for installing the lower plate assembly.

[0040] The cam divider 18 is a four-position cam divider. The cam divider 18 is driven by the main motor 16 through the belt drive 15 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com