Roll Crusher

A pair of roller crusher and passive roller technology, which is applied in solid separation, chemical instruments and methods, grain processing, etc., can solve the problems of large area occupied by the crusher, complex mechanism and cost, etc., so as to avoid blocking the screen and enhance vibration , to avoid the cumulative effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

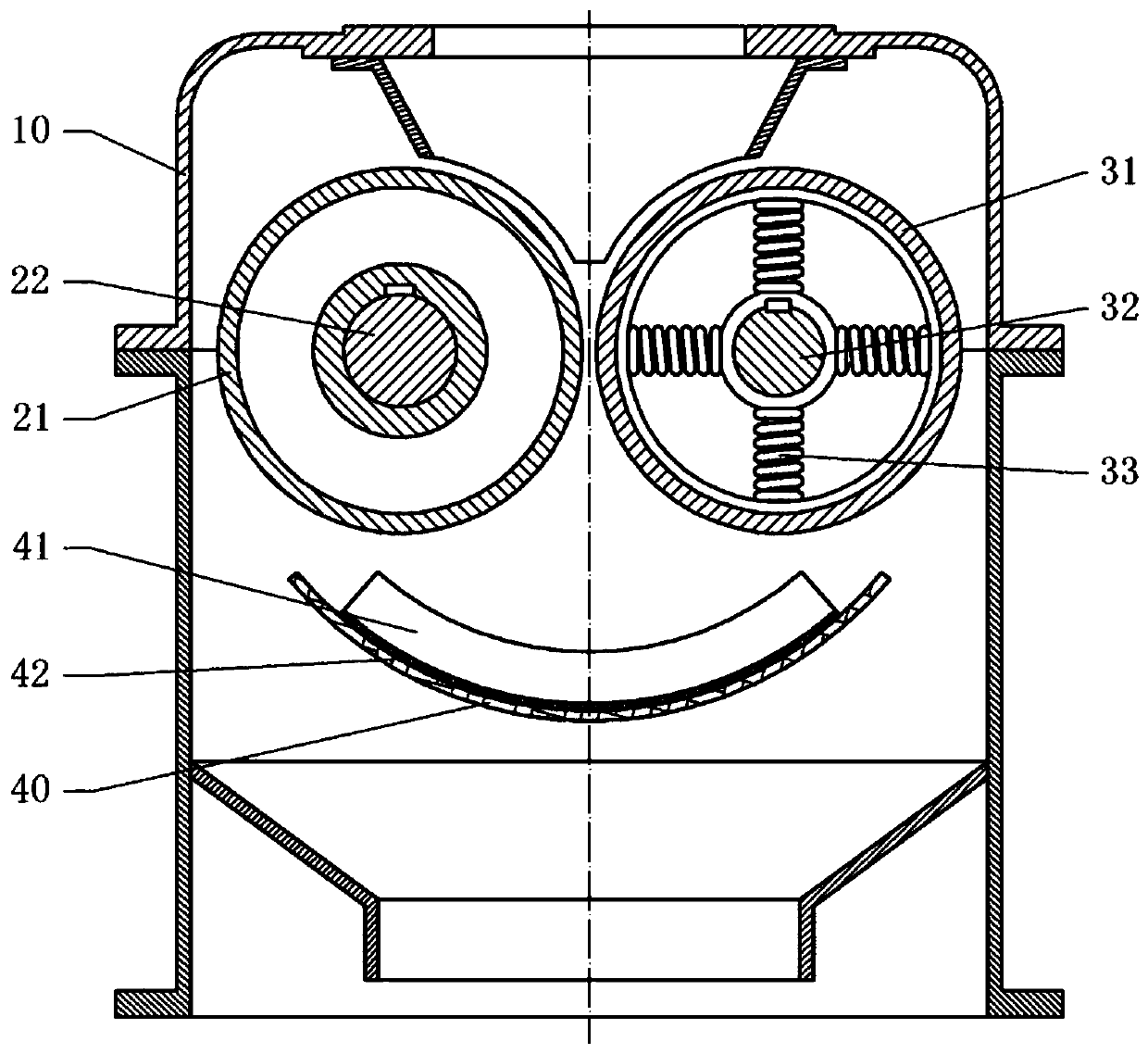

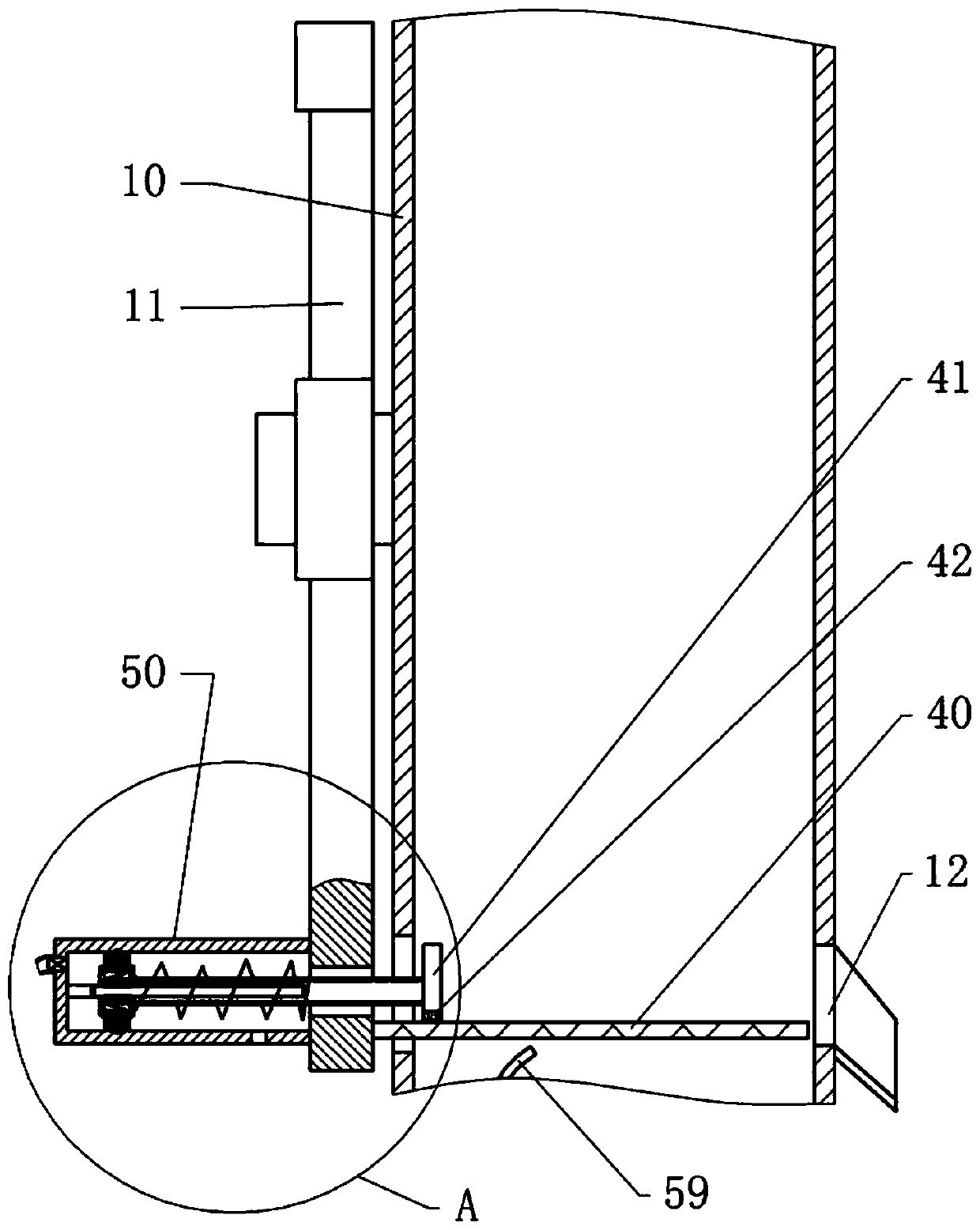

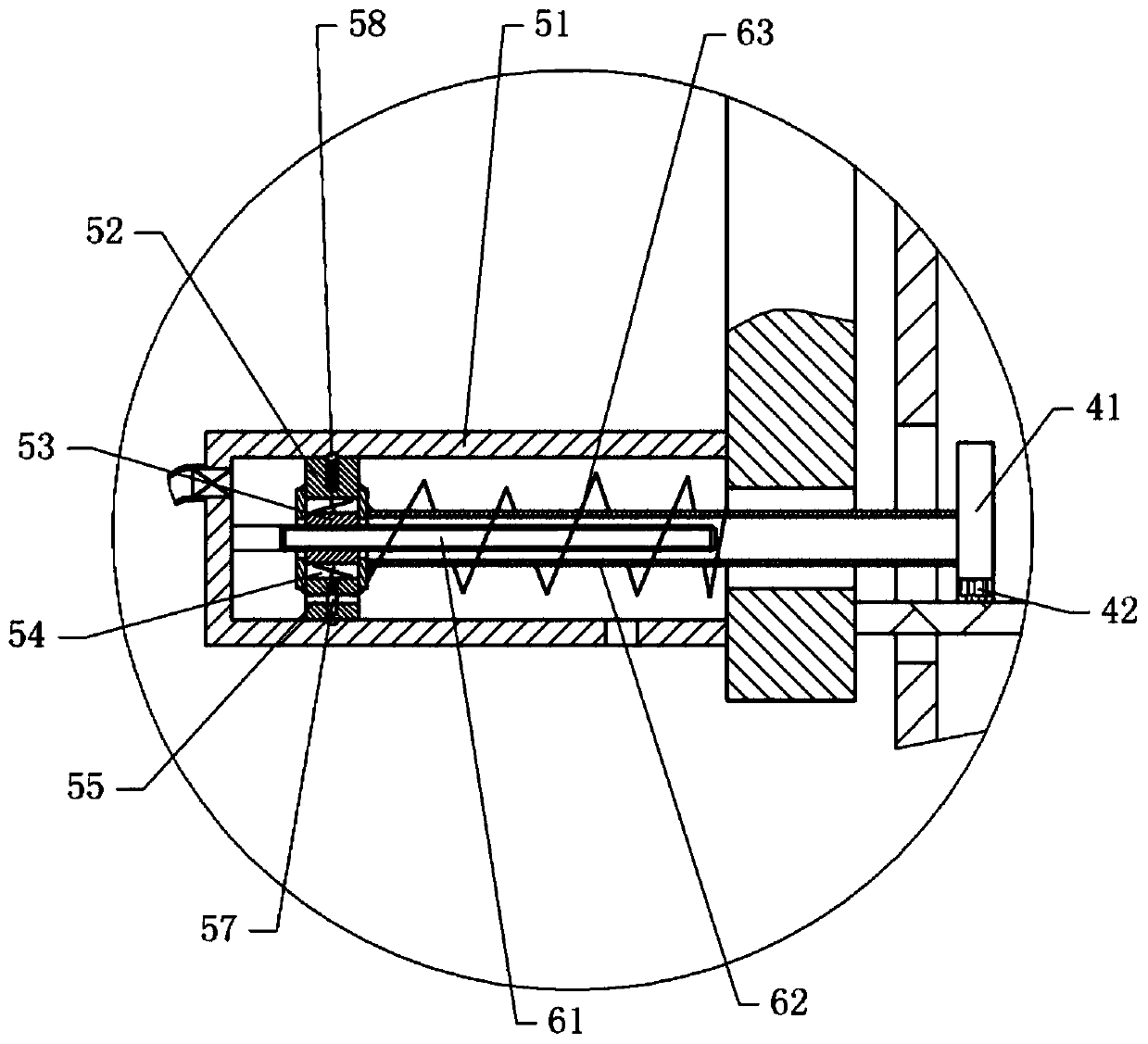

[0028] The reference numerals in the accompanying drawings of the description include: housing 10, swing arm 11, waste material outlet 12, driving roller 21, driving shaft 22, driven roller 31, driven shaft 32, spring 33, screen 40, pushing plate 41, Brush 42, cylinder 50, cylinder body 51, piston 52, rotating block 53, single bearing 54, exhaust hole 55, annular groove 57, steel ball 58, exhaust pipe 59, drive rod 61, push rod 62, compression spring 63, air pump 70, arc driving rod 71.

[0029] Such as figure 1 As shown, the double-roll crusher includes a housing 10, a crushing part located at the upper part of the housing 10 and a screening part located at the lower part of the housing 10. The crushing part includes bearings, driving roller assemblies, driven roller assemblies, synchronous gears and transmission devices. The driving roller assembly and the passive rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com