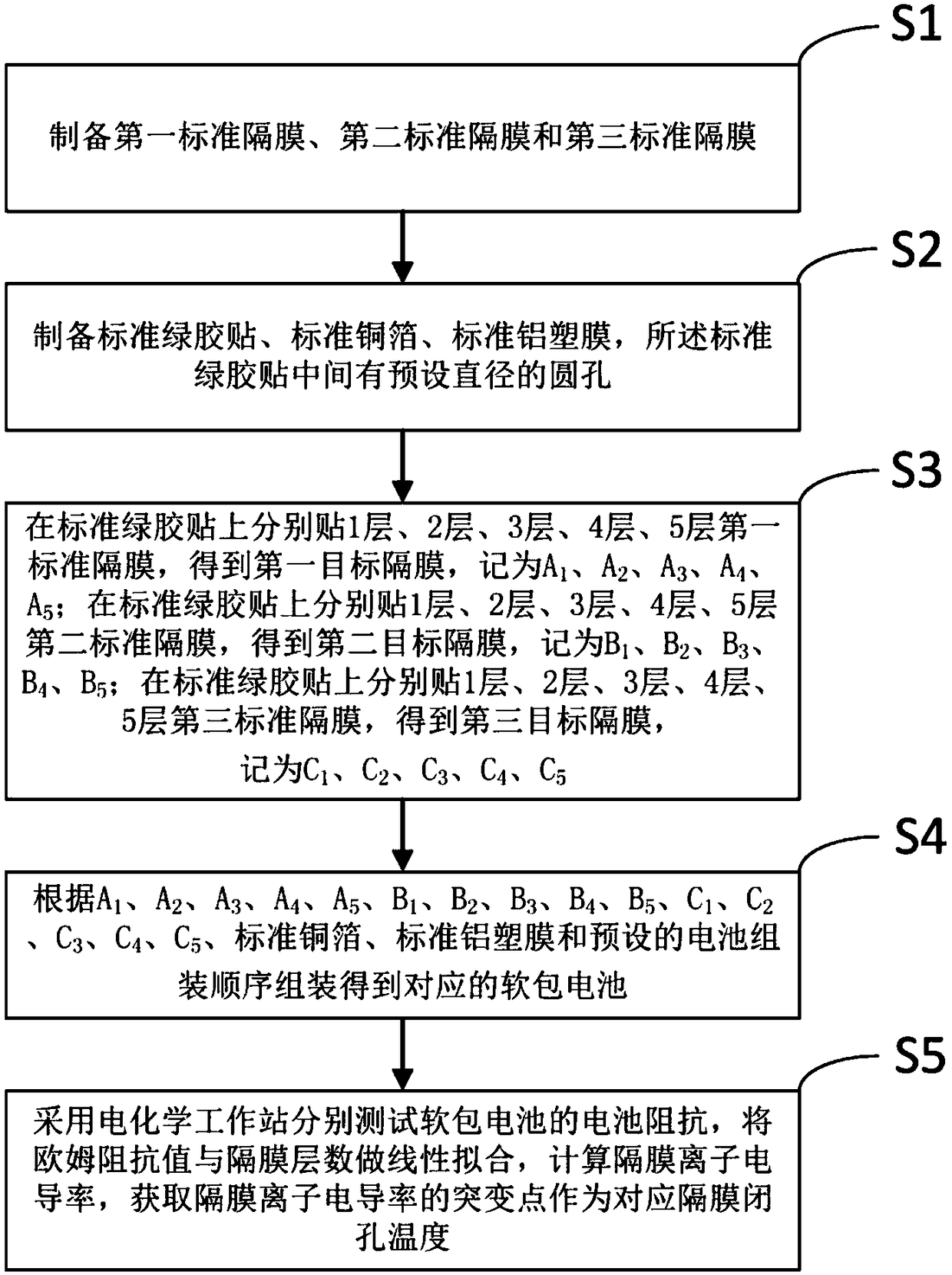

Method for testing pore closing temperature of diaphragm

A closed-cell temperature and test method technology, applied in thermometers, thermometer applications, measuring devices, etc., can solve the problems of test result influence, resistance increase, electrolyte volatilization and decomposition, etc., to achieve simple and reliable test methods, accurate measurement, The effect of high data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

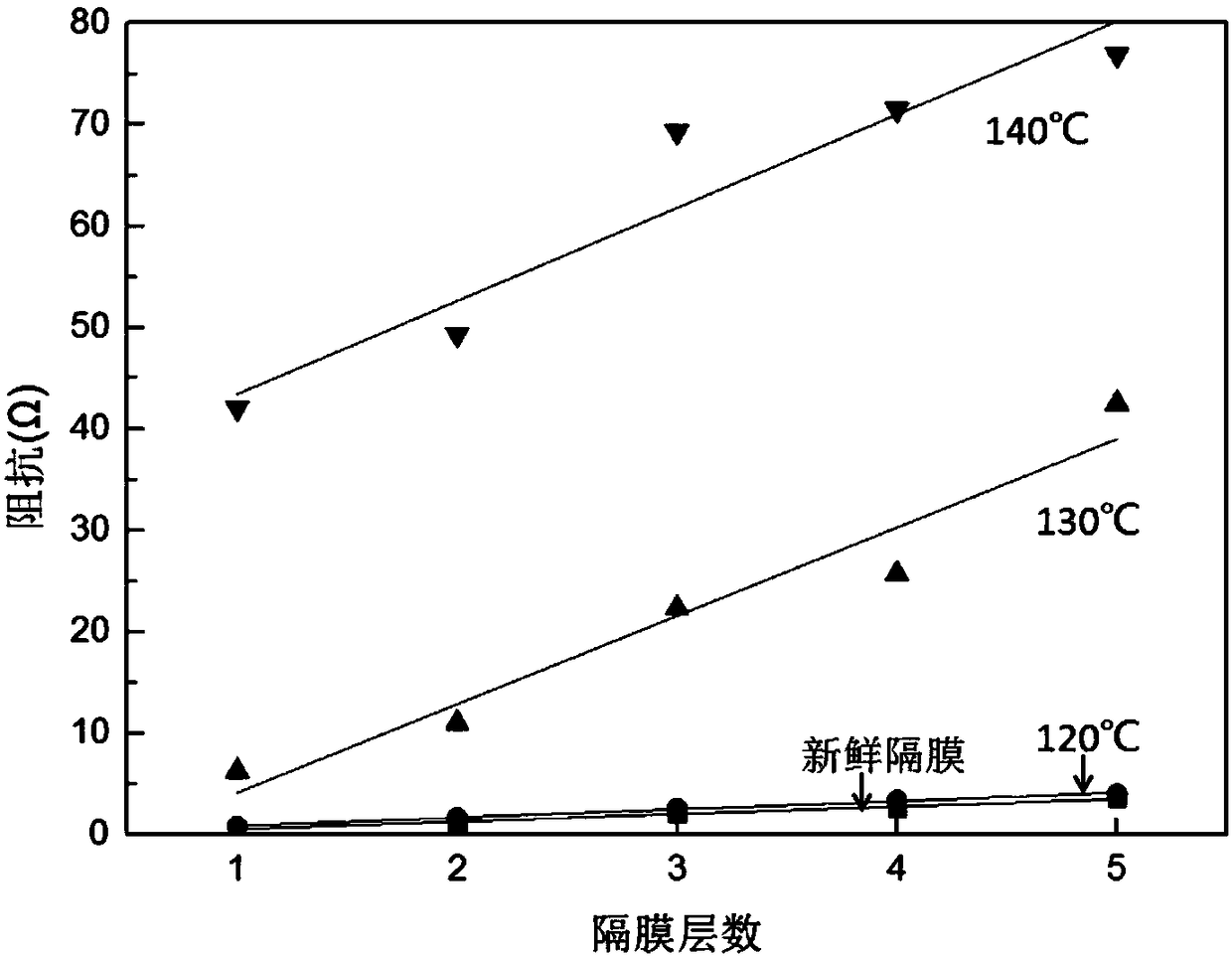

[0042] Heat the 12-micron PE base film at different temperatures of 120°C, 130°C, and 140°C to obtain diaphragms treated at different temperatures, and then use a knife die to punch the diaphragm into several square sheets of 41mm×30mm. Paste the green glue on the dust-free paper, punch it into several square sheets of 50mm×32mm with a die cutter, and punch a round hole with a diameter of 12mm in the middle with a puncher; peel the green glue from the dust-free paper Open, paste the diaphragms treated at different temperatures on the green glue, and paste 1 layer, 2 layers, 3 layers, 4 layers, and 5 layers respectively. Punch 8 micron thick copper foil into several square sheets of 39mm×28mm with a knife die; punch 86 micron thick aluminum-plastic film into several square sheets of 60mm×80mm with a knife die; according to the order from top to bottom The sequence of standard aluminum-plastic film, standard copper foil, separator, standard copper foil, and standard aluminum-pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com