Automatic soil particle measuring experimental device

A technology of automatic measurement and experimental device, applied in the direction of measurement device, particle and sedimentation analysis, and weighing by removing certain components, it can solve the problems of occupying labor time, reducing labor efficiency, and increasing labor intensity. The effect of saving test cost and time, improving automation and labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

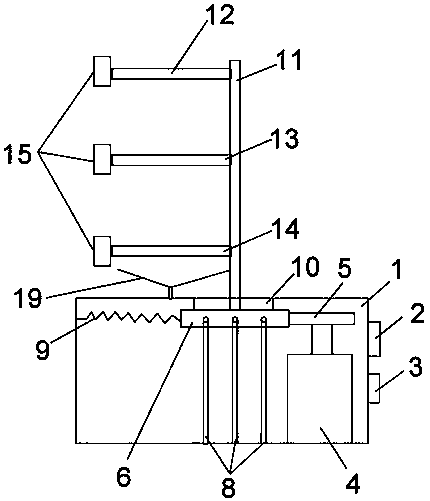

[0019] Embodiment 1: as figure 1 As shown, a soil particle automatic measuring device, a wireless signal receiving processor 2 and a display 3 are installed on the side wall of its box body 1, a motor 4 is fixedly installed inside the box body 1, and a motor 4 is fixedly installed on the output shaft of the motor 4 The cam 5 is in sliding contact with the vibrating table 6, the lower surface of the vibrating table 6 is provided with a first group of notches 7, the lower end of the first group of supporting columns 8 is fixedly connected with the bottom wall of the box body 1, and the top of the first group of supporting columns 8 is connected to the bottom wall of the box body 1. The inner top wall of the first group of notches 7 is in sliding contact, one end of the spring 9 is fixedly connected to the side of the vibrating table 6, the other end of the spring 9 is fixedly connected to the side wall of the box body 1, and the upper surface of the box body 1 is provided with a ...

Embodiment 2

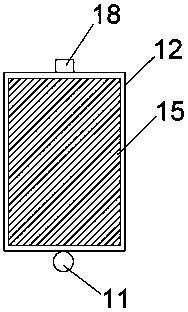

[0021] Embodiment 2: A kind of soil particle automatic measuring device, its box body 1 side wall is installed with wireless signal receiving processor 2, display 3, inside box body 1 is fixedly installed with motor 4, is fixedly installed on the output shaft of motor 4 There is a cam 5, the cam 5 is in sliding contact with the vibrating table 6, and the lower surface of the vibrating table 6 is provided with a first group of notches 7, such as figure 2 , the first group of notches 7 includes three notches, the lower end of the first group of supporting columns 8 is fixedly connected with the bottom wall of the box body 1, the number of the first group of supporting columns 8 is three, the top of the first group of supporting columns 8 is connected to the first The inner top wall of the group notch 7 is in sliding contact, one end of the spring 9 is fixedly connected to the side of the vibrating table 6, the other end of the spring 9 is fixedly connected to the side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com