Rotating piece temperature measuring device and method based on thermochromic liquid crystal

A thermochromic liquid crystal and temperature measuring device technology, which is applied in measuring devices, temperature measurement of moving solids, thermometers with physical/chemical changes, etc. Test complexity and other issues to achieve image stabilization, reduced difficulty, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

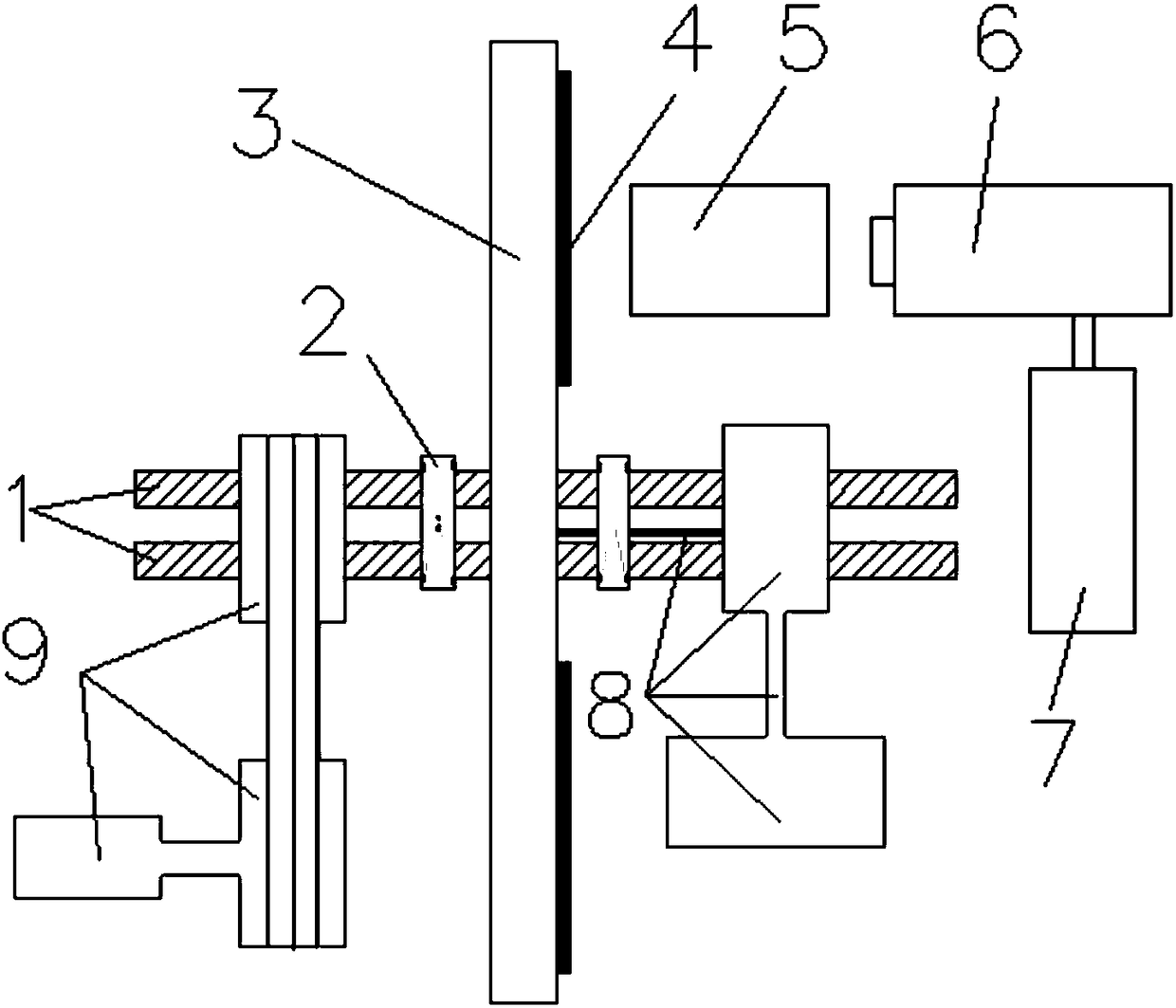

[0022] like figure 1 As shown, the present invention includes a heating device 8, a motor and a transmission device 9, a support bearing 2, a rotating member 3, a thermochromic liquid crystal film 4, an image derotator 5, a photographing device 6, and a signal processing device 7.

[0023] Wherein, among the present invention, each component installation mode is as follows: rotating member 3, motor and transmission device 9 and support bearing 2 are installed on the main shaft 1; Support bearing 2 is in order to support main shaft 1; Motor and transmission device 9 drive main shaft 1 and then make The rotating part 3 rotates; the heating device 8 is connected with the rotating part 3, and the rotating part 3 can be heated by the heating device 8; the thermochromic liquid crystal film 4 is arranged on the surface of the rotating part 3, and the thermochromic liquid crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com