Measurement platform device

A technology for measuring platforms and tanks, which is applied in the field of measuring platforms, can solve the problems of reducing measurement accuracy, poor sliding effect, affecting the stability and smoothness of offset seat 50, etc., so as to avoid component torque and increase structure The effect of mounting the contact surface, improving accuracy and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] In order to have a further understanding and understanding of the purpose, characteristics and effects of the present invention, please cooperate with the [simplified description of the drawings] to describe in detail as follows:

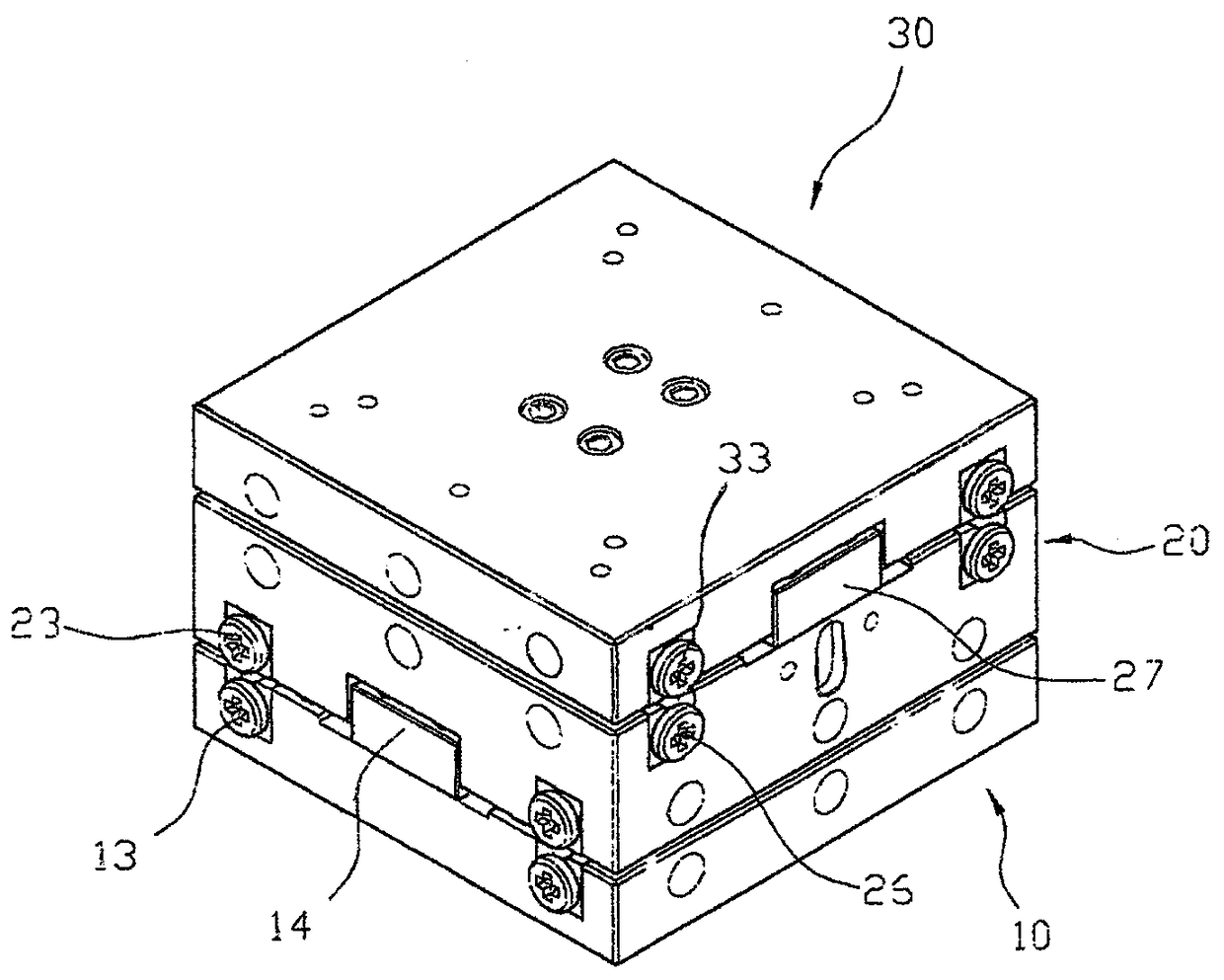

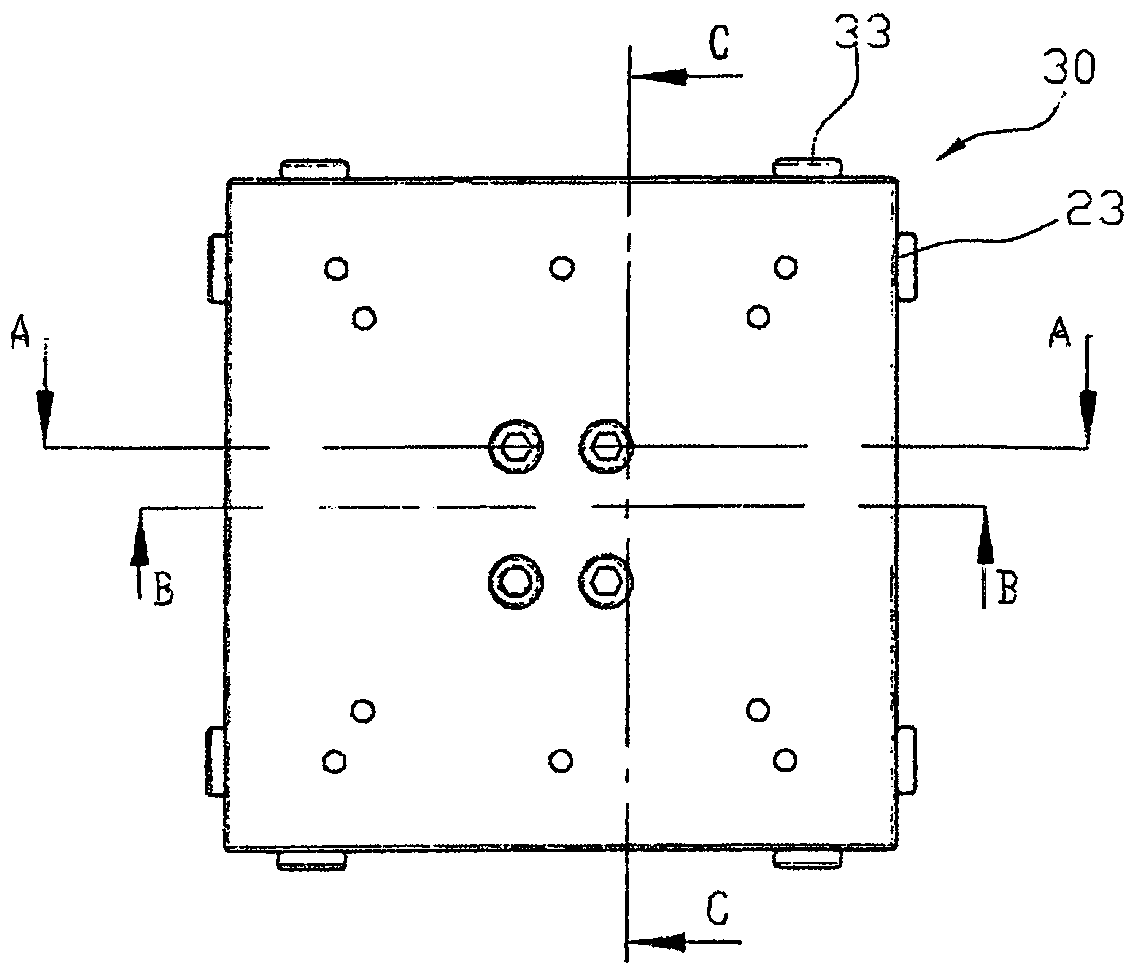

[0080] First, please see figure 1 , figure 2 Cooperate image 3 , Figure 4 Shown, a kind of measuring platform device, it comprises: a lower base 10, a slide seat 20, the upper surface of this lower base 10 has two parallel first cavities 11, and one between two first cavities 11 There are inter-connecting slots 12 parallel to each other, a first slider 13 is fixed in the two first containing slots 11, and a taper groove 131 is provided on the surface ends of the two first sliders 13, and the front, The rear end is provided with an X-axis stop block 14, and then a guide rail 15 is fixed in the joint groove 12, and a first limit slide 16 is also configured to slide and limit on the guide rail 15. The guide rail Both sides of the rod 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com