Prefabricated fast-mounted lattice beam system and construction method thereof

A lattice beam and system technology, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of inability to realize industrialization, variable slope terrain, long construction period and low efficiency, etc. The effect of low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Such as Figure 4 As shown, the prefabricated quick-installed lattice beam system and its construction method provided by the present invention, the lattice beam system is in the shape of a square, and the lattice beam system includes a third module 3 and three first modules 1, two adjacent modules The first modules 1 are connected by at least three third modules 3 .

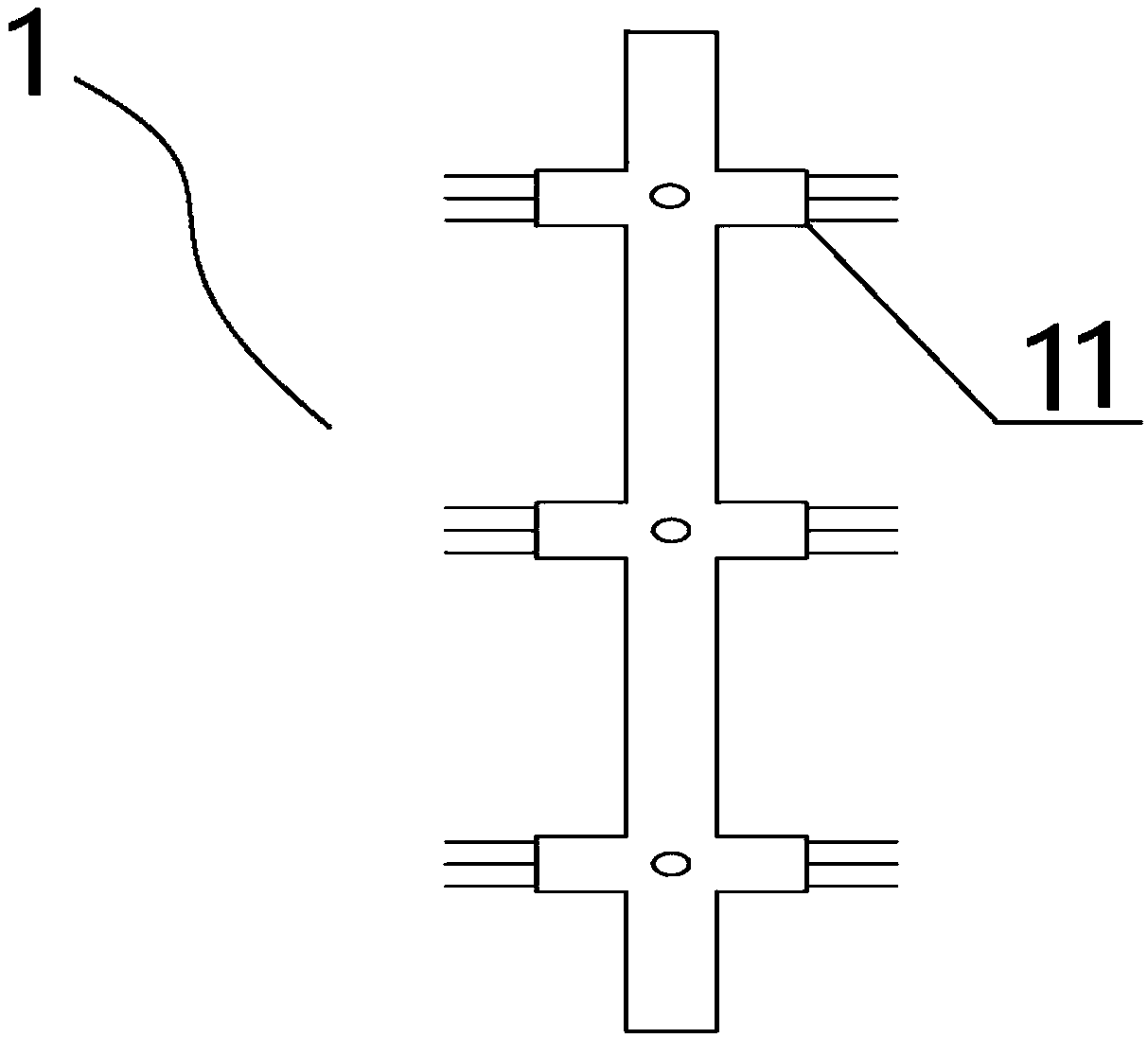

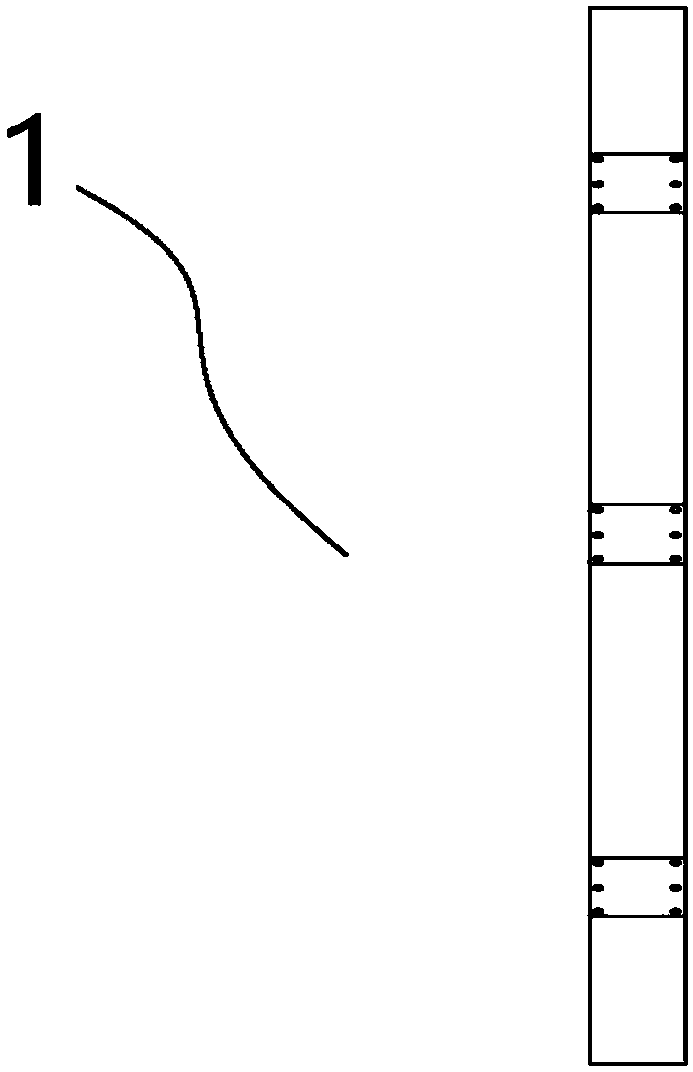

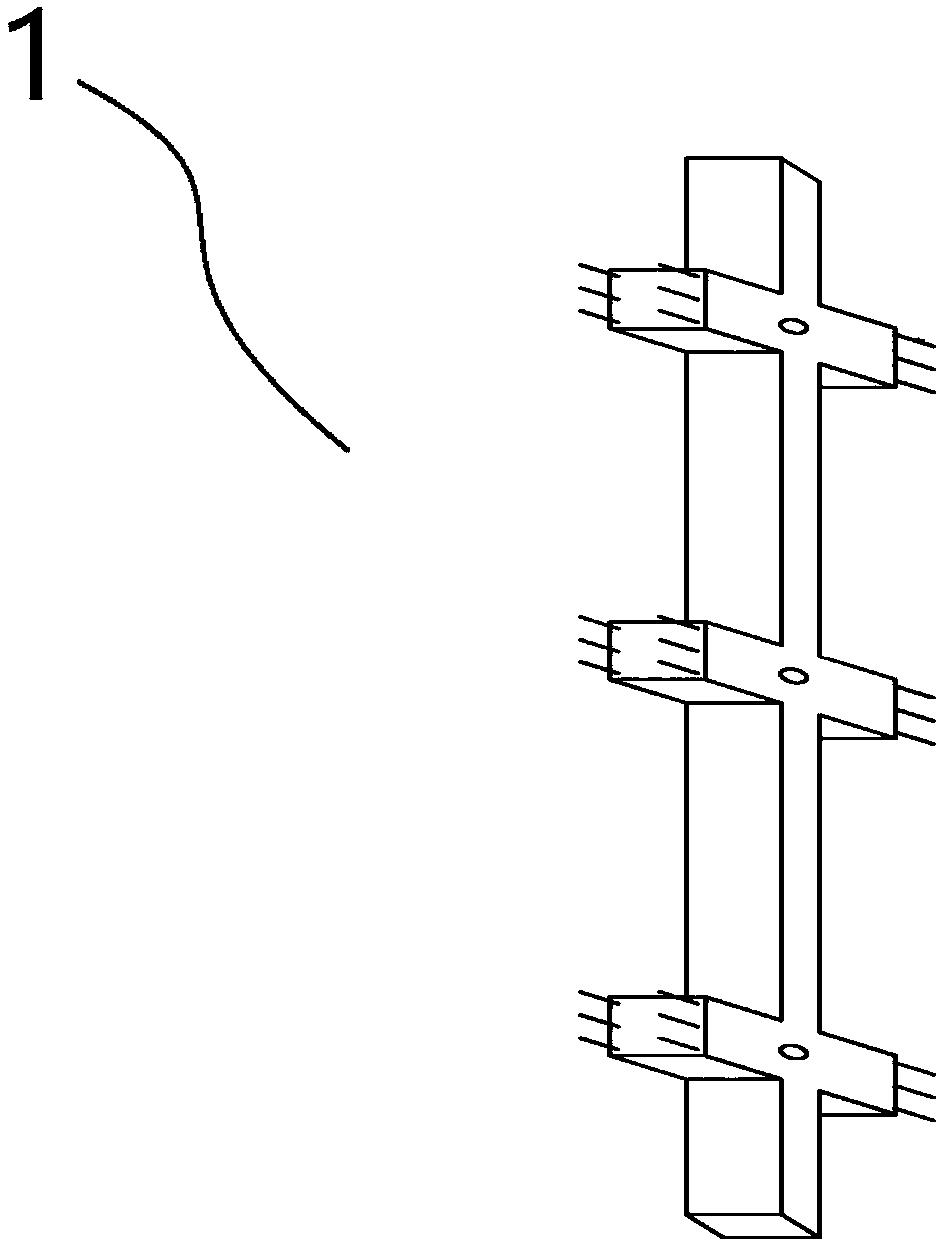

[0042] see also Figure 3a , 3b and 3c, the third module 3 includes an inline-shaped reinforced concrete beam and third joints 31 arranged at both ends of the beam, and the steel bars in the third joint 31 protrude out of the concrete. The first module 1 includes reinforced concrete longitudinal girders, first joints 11 symmetrically arranged on both sides of the longitudinal girder body, and holes for passing anchor rods. The steel bars in the first joints 11 protrude out of the concrete; the holes are located at The intersection of the first joint 11 and the longitudinal beam is arranged through the ...

Embodiment 2

[0054] Such as Figure 5 As shown, the prefabricated quick-installed lattice beam system and construction method thereof provided by the present invention, the lattice beam system is in the shape of a square, including three first modules 1, such as Figure 1a , 1b As shown in and 1c, the first module 1 includes reinforced concrete longitudinal beams, first joints 11 symmetrically arranged on both sides of the longitudinal beam body and holes for passing through anchor rods, and the steel bars in the first joints 11 protrude Outside the concrete; the hole is located at the intersection of the first joint 11 and the longitudinal beam, and is arranged through the body of the longitudinal beam; three pairs of first joints 11 are arranged symmetrically on both sides of the longitudinal beam. Two adjacent first modules 1 are connected in a way of binding and lapping through steel bars protruding from the first joint 11 . The reinforcement joints are filled with strength grade fine...

Embodiment 3

[0065] Such as Figure 6 As shown, the prefabricated and quick-installed lattice beam system and its construction method provided by the present invention, the lattice beam system is in the shape of a square, and the lattice beam system includes nine second modules 2, and the two adjacent second modules 2 They are connected by steel bars protruding from the second joint 21.

[0066] see also Figure 2a , 2b and 2c, the second module 2 includes a cross-shaped reinforced concrete prefabricated part, a hole arranged in the center of the cross-shaped reinforced concrete prefabricated part, and second joints 21 arranged at the four ends of the prefabricated part. The steel bar in the two joints 21 stretches out of the concrete. The steel bars are connected by tying and overlapping. The reinforcement joints are filled with strength grade fine stone concrete. The lattice beam system is arranged horizontally, and the two ends of the lattice beam are fixedly connected with the sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com