Fluorine-containing paint and preparation method thereof, and fluorine release film based on coating by fluorine-containing paint

A technology of fluorine-containing coatings and basic coatings, applied in the direction of fireproof coatings, epoxy resin coatings, chemical instruments and methods, etc., can solve the problem of affecting the normal use of the release film, generation of debris and burrs, and poor die-cutting effect of the release film. Good and other problems, to achieve the effect of mild conditions, stable release force and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

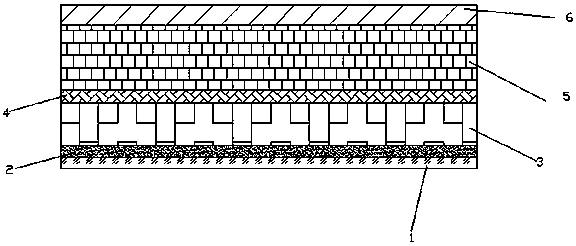

Image

Examples

Embodiment 1

[0026] A preparation method of fluorine-containing paint, comprising the steps of:

[0027] S1, weigh 13g of fluorine-containing epoxy resin, 30g of base paint, 35g of n-heptane, 3.5g of ethylene-acrylic acid copolymer, 17.5g of ethylene glycol amine, and 1g of pH regulator;

[0028] S2, take the basic paint in S1, mix n-heptane and ethylene-acrylic acid copolymer, stir, disperse evenly, and heat the system temperature to 40-50°C;

[0029] S3, add fluorine-containing epoxy resin, ethylene glycol amine and pH regulator to the reaction system of S2 in sequence, adjust the temperature of the system to 40-50° C., and react at constant temperature for 5 hours.

Embodiment 2

[0031] A preparation method of fluorine-containing paint, comprising the steps of:

[0032] S1, weigh 15g of fluorine-containing epoxy resin, 45g of base paint, 15g of n-heptane, 5g of ethylene-acrylic acid copolymer, 18g of ethylene glycol amine, and 2g of pH regulator;

[0033] S2, take the basic paint in S1, mix n-heptane and ethylene-acrylic acid copolymer, stir, disperse evenly, and heat the system temperature to 40-50°C;

[0034] S3, add fluorine-containing epoxy resin, ethylene glycol amine and pH regulator to the reaction system of S2 in sequence, adjust the temperature of the system to 40-50° C., and react at constant temperature for 5.5 hours.

Embodiment 3

[0036] A preparation method of fluorine-containing paint, comprising the steps of:

[0037] S1, weigh 5g of fluorine-containing epoxy resin, 45g of base paint, 28g of n-heptane, 2g of ethylene-acrylic acid copolymer, 18g of ethylene glycol amine, and 2g of pH regulator;

[0038] S2, take the basic paint in S1, mix n-heptane and ethylene-acrylic acid copolymer, stir, disperse evenly, and heat the system temperature to 40-50°C;

[0039] S3, adding fluorine-containing epoxy resin, ethylene glycol amine and pH regulator to the reaction system of S2 in sequence, adjusting the temperature of the system to 40-50° C., and reacting at a constant temperature for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com