Air cooling device for tempered glass

A technology of tempered glass and cooling device, applied in the direction of glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of stress spots, affecting the appearance of products, stress difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further detailed explanation through specific implementation mode below:

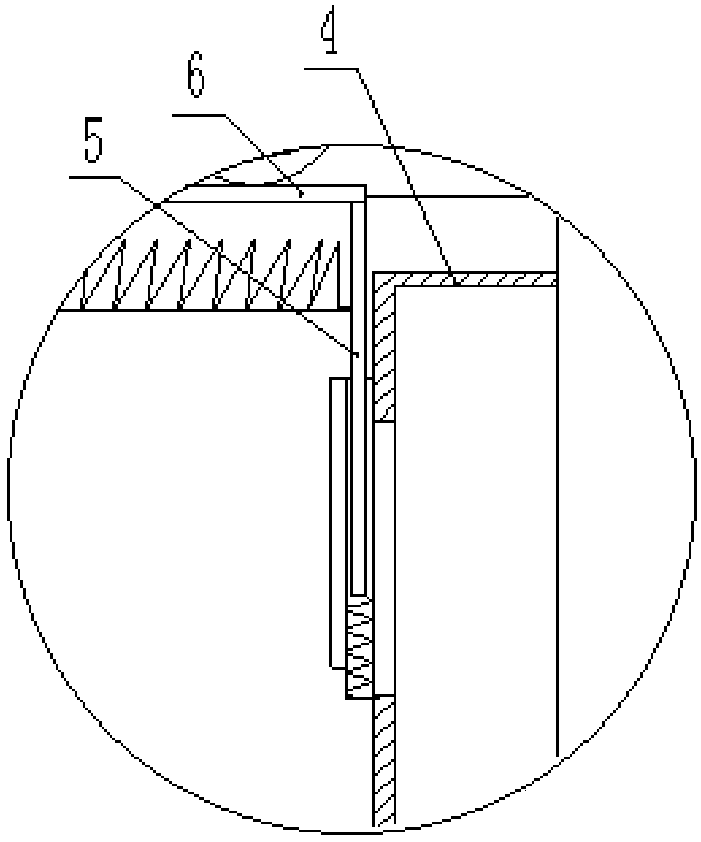

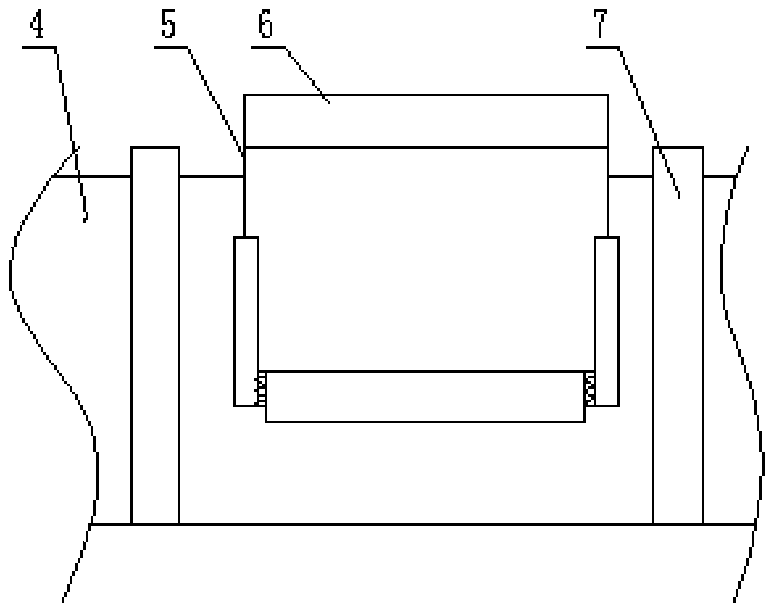

[0023] The reference signs in the drawings of the specification include: upper air grille 1, lower air grille 2, windshield plate 3, exhaust pipe 4, cover body 5, extension body 6, partition plate 7, wind blocking brush 8, wave plate 9 , Drive roller 10, flange 11.

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the air-cooled cooling device for tempered glass includes transversely distributed drive rollers 10 , an upper air grille 1 located above the drive rollers 10 and a lower air grille 2 located below the drive rollers 10 . Wherein, the driving roller 10 is arranged vertically, the horizontal direction refers to the driving direction of the driving roller 10 from left to right, and the longitudinal direction refers to the direction perpendicular to the driving direction of the driving roller 10 . The drive roller 10 is wound with an arami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com