Clamping mechanism

A clamping mechanism and locking sleeve technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing the complexity of the tooling mechanism, being unable to install pressure clamps nearby, and increasing the manufacturing cost. It is convenient for unified production and management, convenient for rational use of space, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

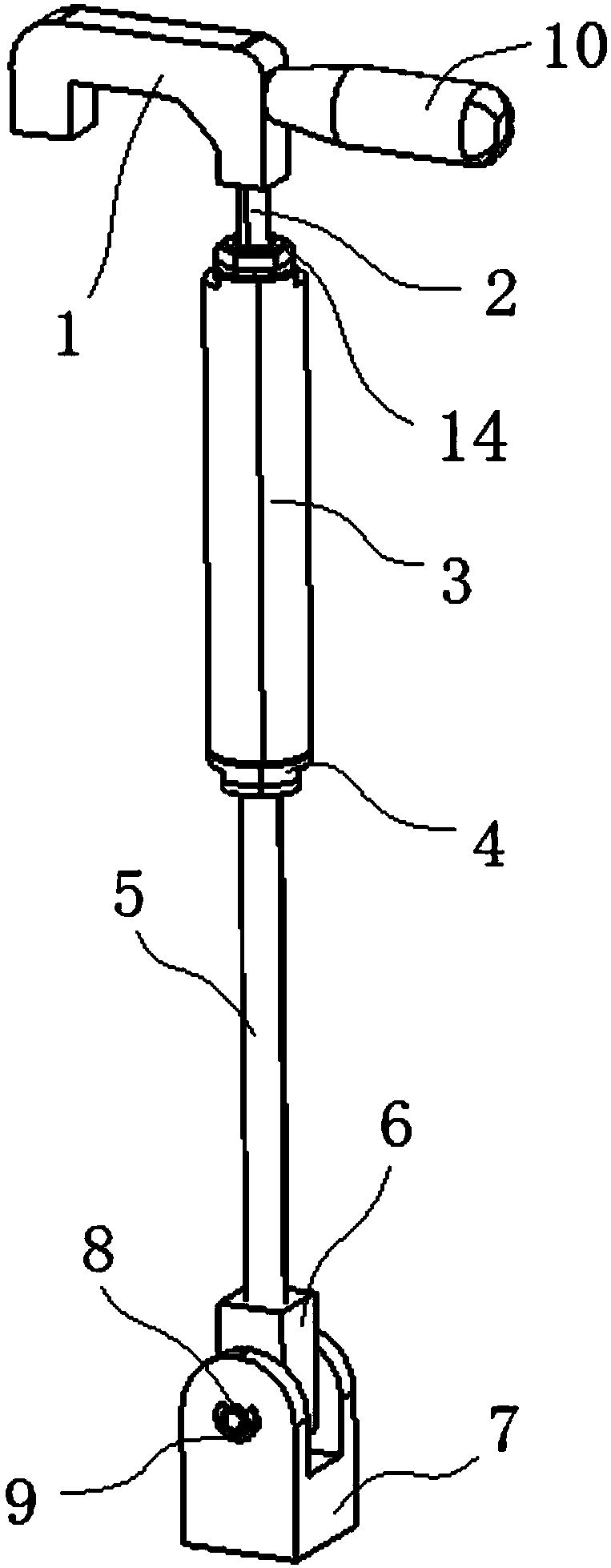

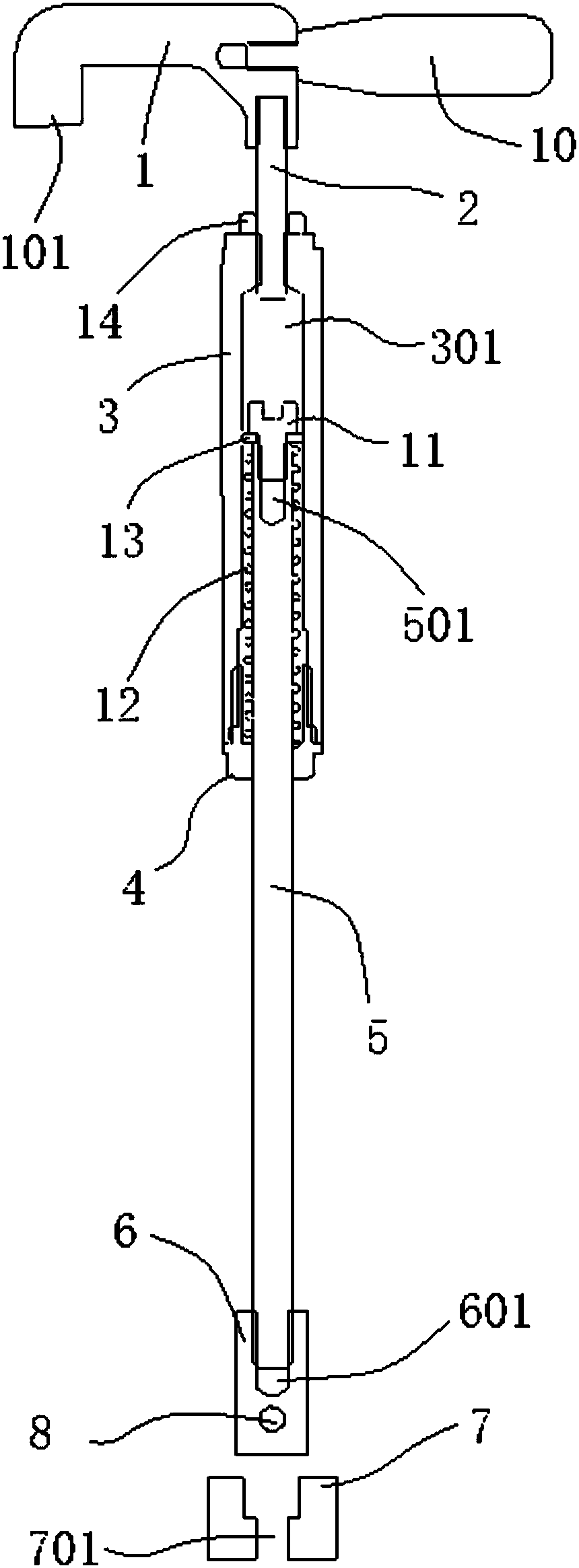

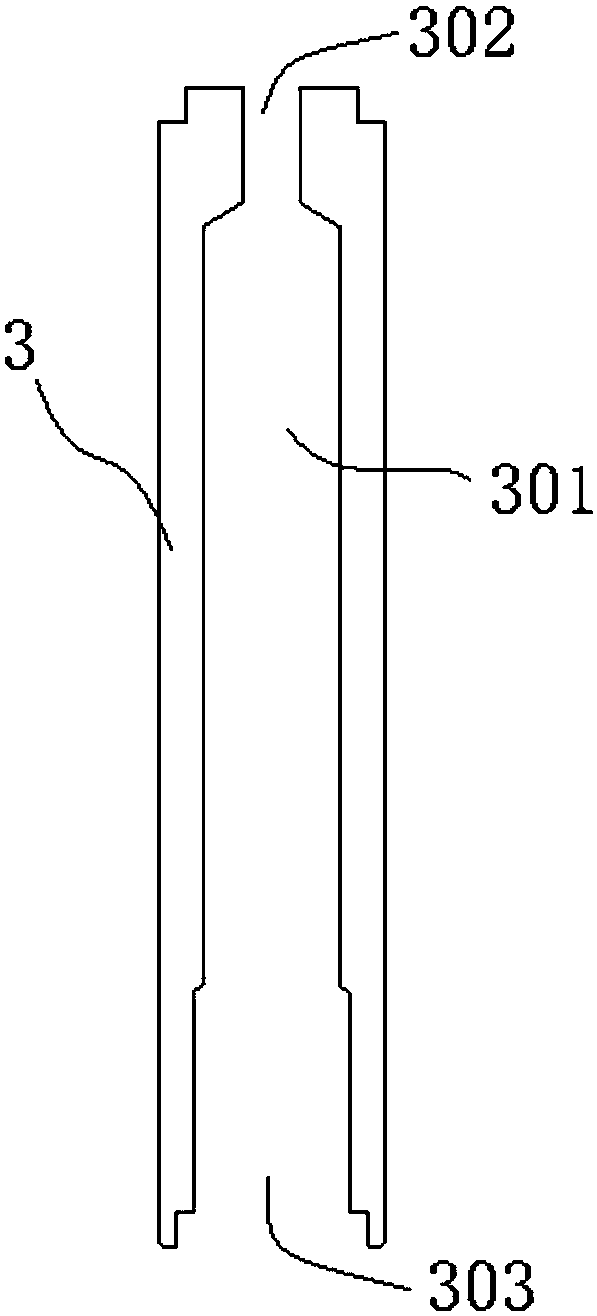

[0031] like figure 1 and figure 2 As shown, the embodiment of the present invention provides a clamping mechanism, including a pressure block 1, a first connecting rod 2, a shaft sleeve 3, a locking sleeve 4, a second connecting rod 5, a connecting block 6, a base 7, a connecting Shaft 8, stretchable elastic part 12 and limit block 13, one end of briquetting block 1 is provided with pressing part 101, the other end of briquetting block 1 is fixedly connected with the top end of first connecting rod 2, the first connecting rod 2 The bottom end is fixedly connected with the top end of the shaft sleeve 3, and the bottom end of the shaft sleeve 3 is fixedly connected with the locking sleeve 4. The inside of the shaft sleeve 3 has a cavity 301, and the inside of the cavity 301 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com