A pounding grinding device for printing ink pigments

A grinding device and printing ink technology, applied in grain processing, etc., can solve the problems of impossibility of printing ink pigment smashing grinding, uneven grinding of printing ink pigment, single grinding method, etc., to achieve easy maintenance, good grinding effect, The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

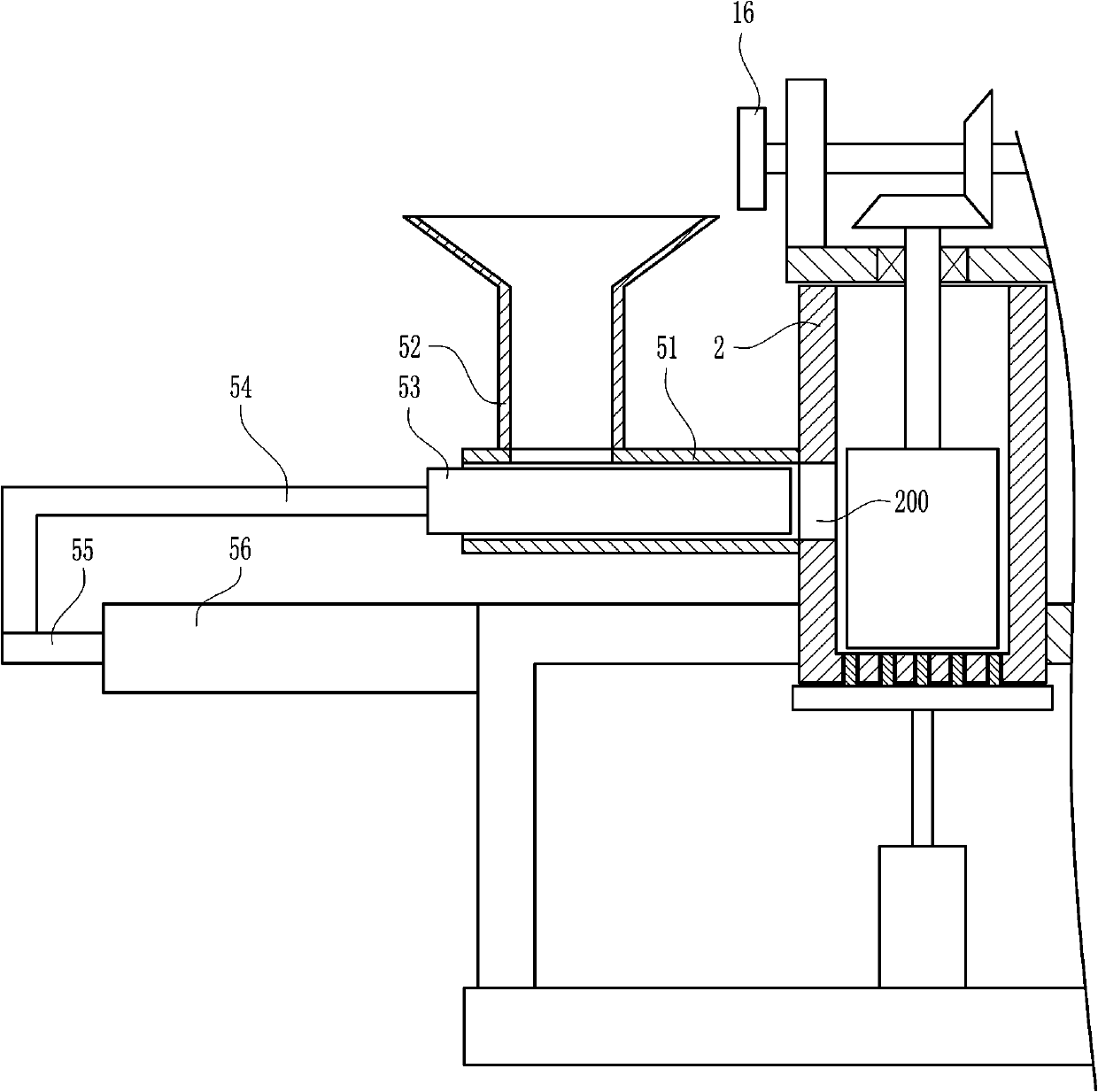

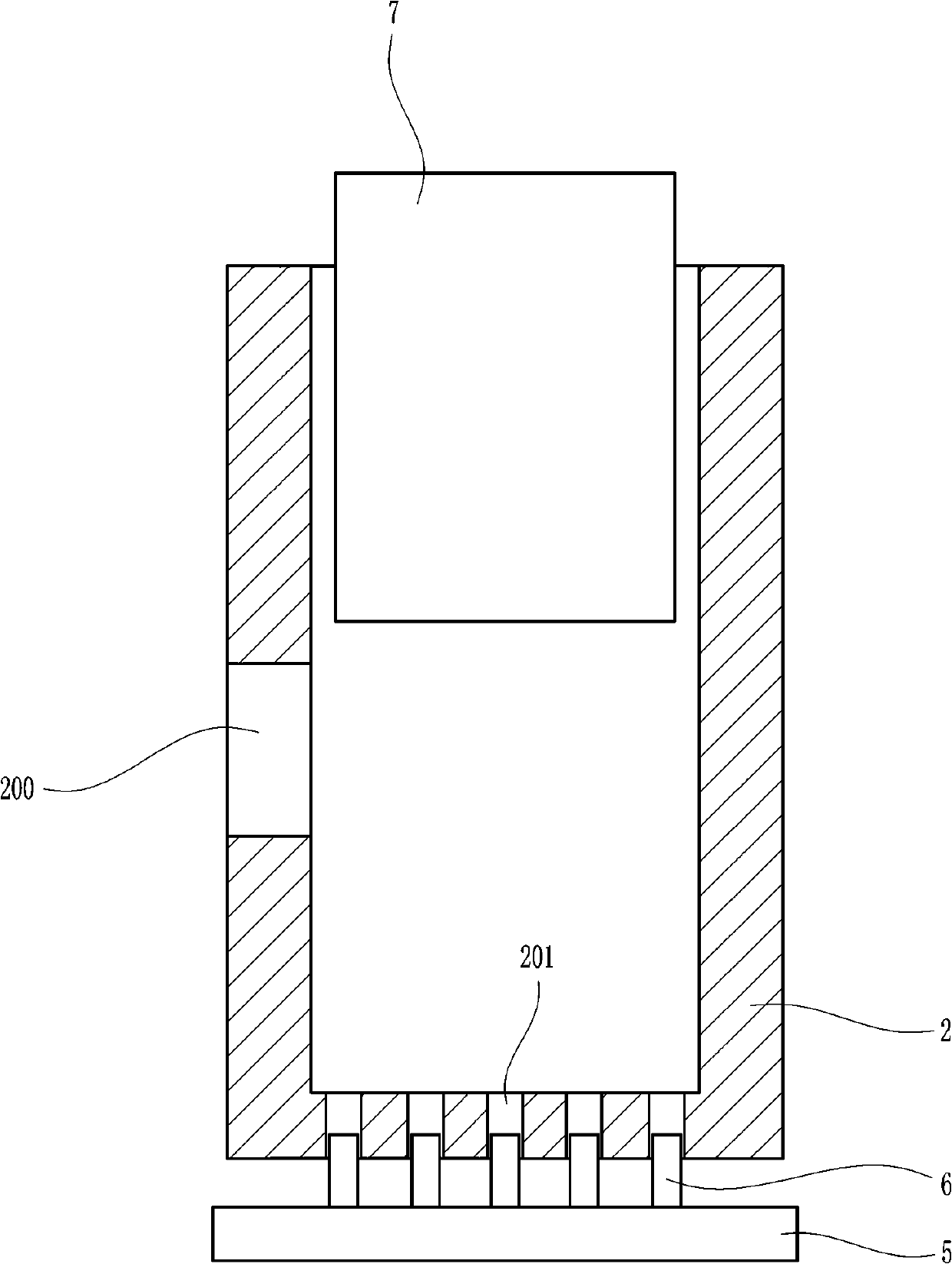

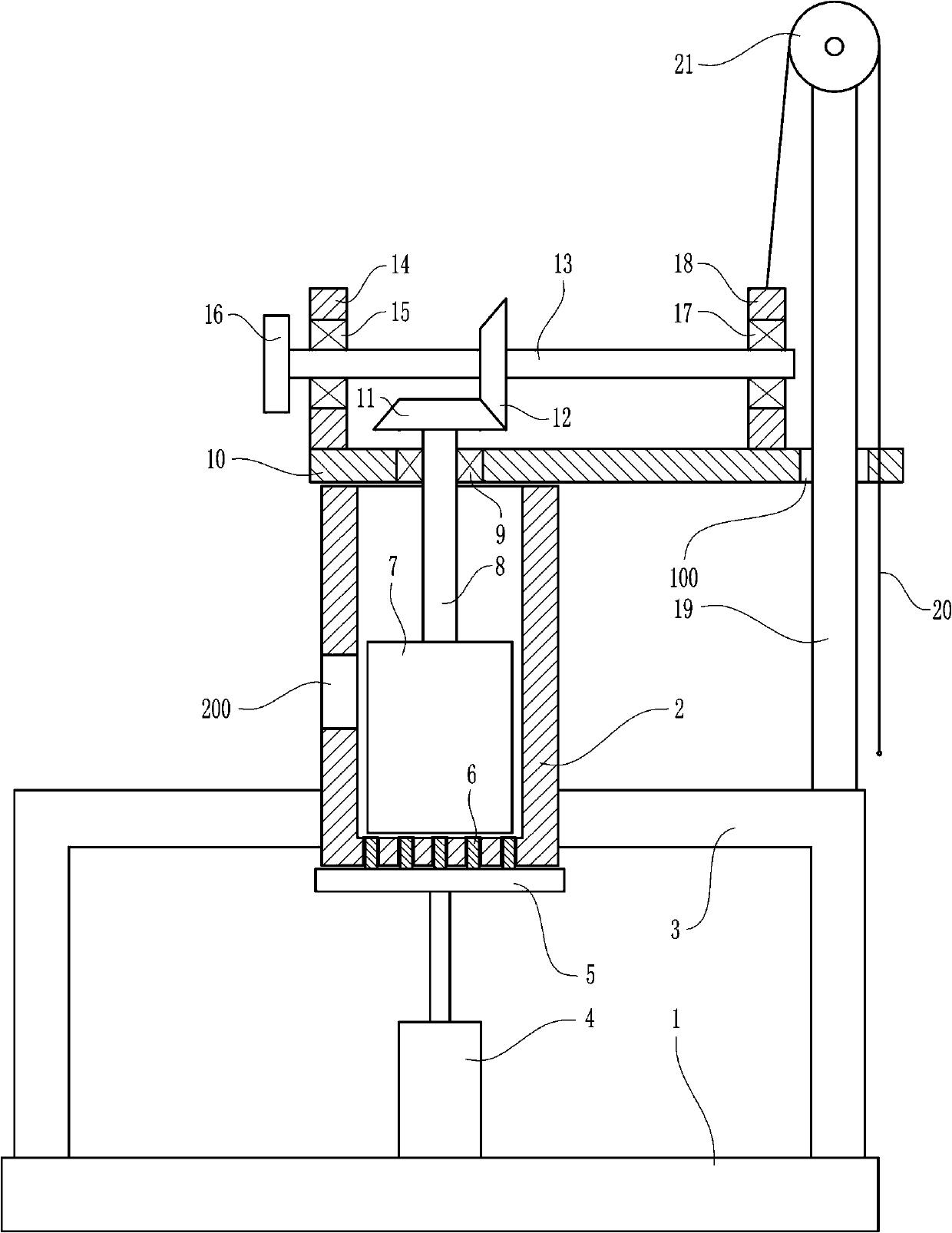

[0028] A smashing grinding device for printing ink pigments, such as Figure 1-6 As shown, it includes a base 1, a cylinder body 2, an L-shaped leg 3, an upper and lower cylinder 4, a supporting plate 5, a plunger 6, a grinding column 7, a first connecting shaft 8, a first bearing 9, a movable plate 10, the first A bevel gear 11, a second bevel gear 12, a second connecting shaft 13, a first fixed plate 14, a second bearing 15, a rotating disc 16, a third bearing 17, a second fixed plate 18, a rectangular guide rod 19, and a pull wire 20 and the first pulley 21, the top of the base 1 is provided with a cylinder 2, the left and right sides of the cylinder 2 are symmetrically provided with L-shaped legs 3, the L-shaped legs 3 are connected with the cylinder 2, and the L-shaped legs 3 Located above the base 1, the L-shaped leg 3 is connected to the base 1, the upper and lower cylinders 4 are located directly below the cylinder 2, the bottom of the upper and lower cylinders 4 is co...

Embodiment 2

[0030] A smashing grinding device for printing ink pigments, such as Figure 1-6 As shown, it includes a base 1, a cylinder body 2, an L-shaped leg 3, an upper and lower cylinder 4, a supporting plate 5, a plunger 6, a grinding column 7, a first connecting shaft 8, a first bearing 9, a movable plate 10, the first A bevel gear 11, a second bevel gear 12, a second connecting shaft 13, a first fixed plate 14, a second bearing 15, a rotating disc 16, a third bearing 17, a second fixed plate 18, a rectangular guide rod 19, and a pull wire 20 and the first pulley 21, the top of the base 1 is provided with a cylinder 2, the left and right sides of the cylinder 2 are symmetrically provided with L-shaped legs 3, the L-shaped legs 3 are connected with the cylinder 2, and the L-shaped legs 3 Located above the base 1, the L-shaped leg 3 is connected to the base 1, the upper and lower cylinders 4 are located directly below the cylinder 2, the bottom of the upper and lower cylinders 4 is co...

Embodiment 3

[0033] A smashing grinding device for printing ink pigments, such as Figure 1-6As shown, it includes a base 1, a cylinder body 2, an L-shaped leg 3, an upper and lower cylinder 4, a supporting plate 5, a plunger 6, a grinding column 7, a first connecting shaft 8, a first bearing 9, a movable plate 10, the first A bevel gear 11, a second bevel gear 12, a second connecting shaft 13, a first fixed plate 14, a second bearing 15, a rotating disc 16, a third bearing 17, a second fixed plate 18, a rectangular guide rod 19, and a pull wire 20 and the first pulley 21, the top of the base 1 is provided with a cylinder 2, the left and right sides of the cylinder 2 are symmetrically provided with L-shaped legs 3, the L-shaped legs 3 are connected with the cylinder 2, and the L-shaped legs 3 Located above the base 1, the L-shaped leg 3 is connected to the base 1, the upper and lower cylinders 4 are located directly below the cylinder 2, the bottom of the upper and lower cylinders 4 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com