Patch infrared diode

A diode and infrared technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as poor reflection and refraction effects, and the product's Y-axis angle cannot meet customer needs, and achieve the effect of changing the luminous angle and improving luminous intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

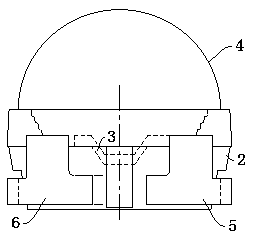

[0019] combine Figure 1 to Figure 4 As shown, this embodiment provides a chip infrared diode, including LED chips 1, and a base 2 for carrying the LED chips 1, a metal reflective cup 3 is buried on the light-emitting side of the base 2, and the metal The bottom of the reflective cup 3 is provided with the LED chip 1, the top of the metal reflective cup 3 is packaged with an optical lens 4, and the metal reflective cup 3 extends outwards with metal contacts, and the metal contacts are connected to the The terminals of the LED chip 1 are electrically connected to form soldering feet of the patch infrared diode.

[0020] Specifically, in this embodiment, a pit is provided in the middle of the upper surface of the base 2, and the metal reflective cup 3 is provided in the pit, and the edges around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com