Anti-loosening connecting mechanism

A connection mechanism and anti-loosening technology, applied in the direction of connecting components, mechanical equipment, threaded fasteners, etc., can solve the problems of vibration, easy loosening, failure of button switch or indicator light function, etc., to increase friction, prevent nut Rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better illustrate and illustrate the content of the present invention, the following descriptions are carried out in conjunction with schematic diagrams and implementation examples:

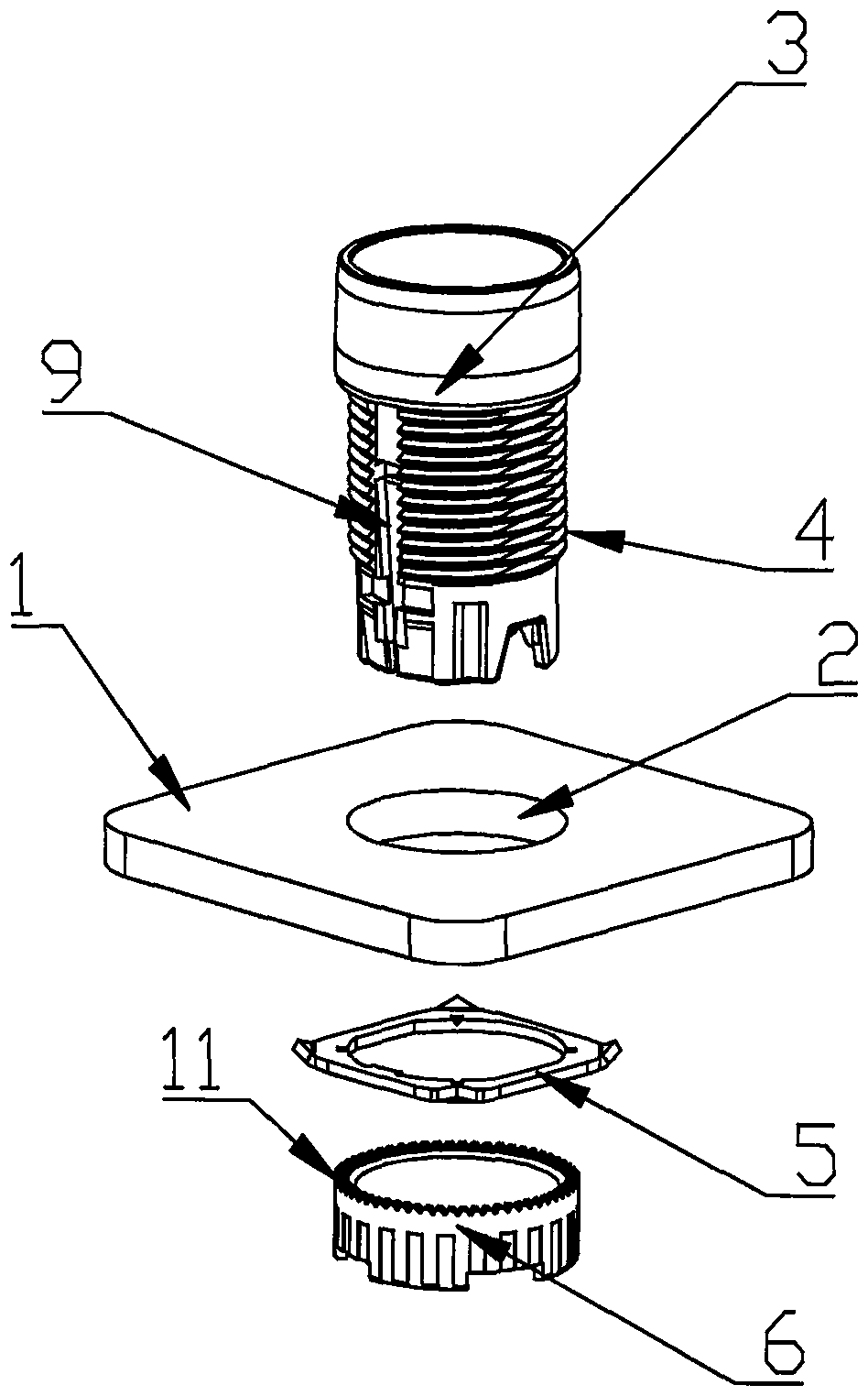

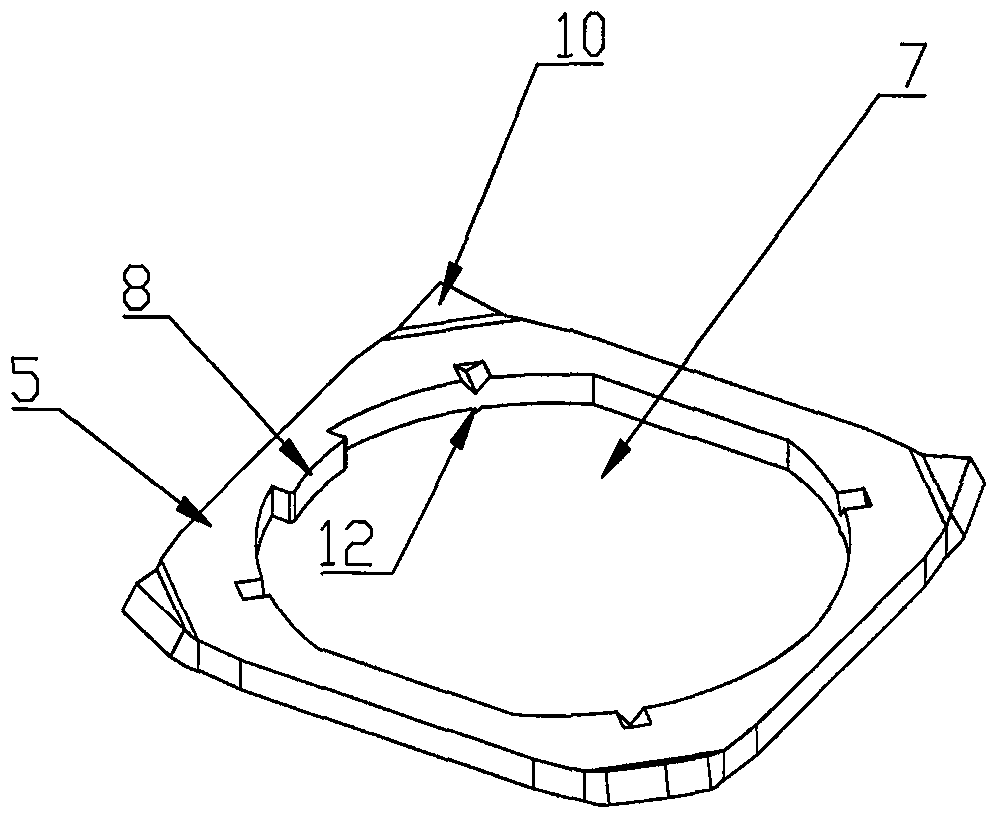

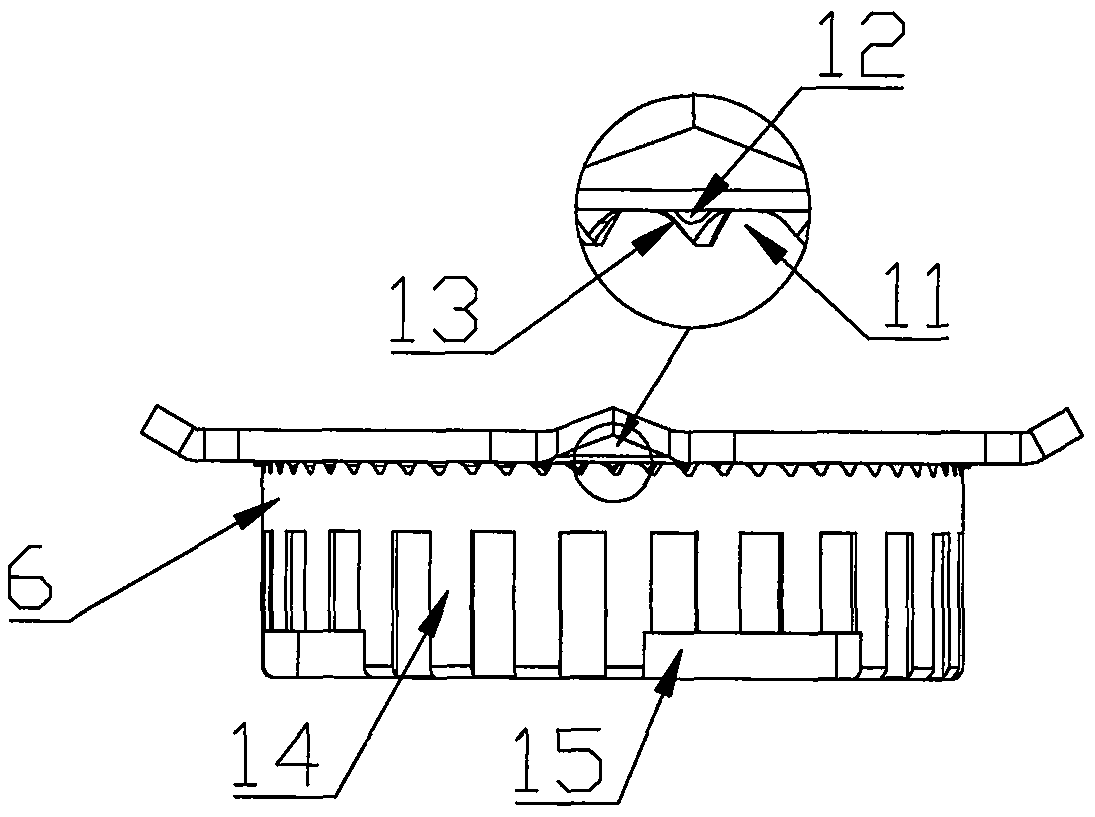

[0025] Depend on Figure 1-Figure 4 As shown, the present invention provides an anti-loosening connection mechanism, which is fixed in the mounting hole 2 of the panel 1; it includes a connecting body 3 of a component product fixed on the panel 1 by a screw connection, a loosening washer 5 and an anti-loosening Nut 6; the bottom of the connection body 3 is provided with a threaded end 4 that can pass through the mounting hole 2 and be threadedly fixed by the locking nut 6, and the middle of the locking washer 5 is provided with a fixing hole 7 for accommodating the threaded end 4 to pass through. The edge of the hole 7 is provided with a positioning bump 8, and one side of the threaded end 4 is provided with a positioning groove 9 that matches the positioning bump 8; the four p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com