Cationic polymer emulsifying wax and its preparation method

A polymer, cationic technology, applied in the field of wax emulsion, can solve the problem of easy delamination of cationic emulsified wax, and achieve the effect of improving hardness, improving stability and increasing aggregation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of cationic macromolecule emulsified wax comprises the following steps:

[0046] Step 1: Preparation of cationic polymer surfactant:

[0047] In terms of mass percentage, take 20% to 50% of the cationic monomer, and the balance is absolute ethanol; dissolve the cationic monomer in absolute ethanol, and then add 0.5% to 2% of the cationic monomer mass. agent to obtain a monomer mixture;

[0048] Pour the above-mentioned monomer mixture into a four-necked flask equipped with a stirrer and a thermometer, pass nitrogen, stir, heat, control the reaction temperature to be 70-85° C., perform reflux reaction for 4-8 hours, cool the obtained product to room temperature, reduce Press distillation to concentrate and remove the solvent to obtain a transparent cationic polymer surfactant;

[0049] Step 2: Preparation of cationic polymer emulsified wax:

[0050] In terms of mass percentage, take 15-45% of the wax and 5-10% of the cationic polymer surfactant ...

Embodiment 1

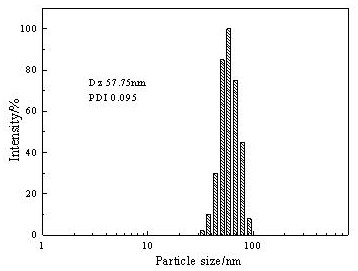

[0054] Dissolve 20% by mass of cationic monomer in absolute ethanol, add oil-soluble initiator azobisisobutyronitrile accounting for 0.5% of the total mass of the monomer, pour the above monomer mixture into a mixer equipped with a stirrer and a thermometer. In the four-necked flask, nitrogen was passed, stirred, heated, the reaction temperature was controlled to be 70°C, and the reaction was refluxed for 4 hours. The surface tension was 42 mN / m (mass concentration 0.2%). Add 15% paraffin and 5% cationic polymer surfactant to the three-necked flask in turn, heat to 65°C, after the two are fully dissolved and mixed, slowly add 65°C hot water under stirring at 1000 rpm, and continue to stir for 30min. That is, the cationic polymer emulsified wax is obtained.

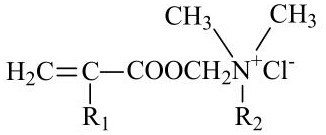

[0055] Among them, the structural formula of the cationic monomer is:

[0056]

Embodiment 2

[0058] Dissolve 35% by mass of cationic monomer in absolute ethanol, add oil-soluble initiator azobisisobutyronitrile accounting for 1% of the total mass of the monomer, pour the above monomer mixture into a mixer equipped with a stirrer and a thermometer. In the four-necked flask, nitrogen was passed, stirred, heated, the reaction temperature was controlled to be 75°C, and the reaction was refluxed for 4 hours. The surface tension was 49 mN / m (mass concentration 0.2%). Add 20% palm wax and 7% cationic polymer surfactant to the three-necked flask in turn, heat to 90°C, after the two are fully dissolved and mixed, slowly add 90°C hot water under stirring at 1000rpm, and continue to stir for 30min , the cationic polymer emulsified wax is obtained.

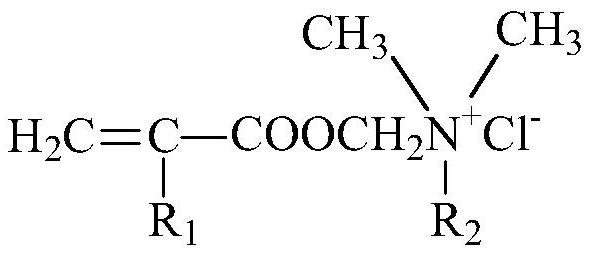

[0059] Among them, the structural formula of the cationic monomer is:

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com