Water evaporation power generation device and preparation method based on ldhs

A water evaporation and device technology, which is applied in the field of LDHs-based water evaporation power generation devices and preparations, to achieve the effect of simple preparation of raw materials and expansion of material range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The LDHs-based water evaporation power generation device of the present invention has a base equipped with tabs and a coating on the base, and the coating is LDHs.

[0022] The preparation method of the LDHs-based water evaporation power generation device of the present invention is carried out as follows:

[0023] a. Preparation of LDHs solid powder:

[0024] Prepare 80ml of nickel nitrate, aluminum nitrate and urea mixed solution, wherein Ni 2+ 、Al 3+ and urea concentrations are respectively 10 mmol / L, 5 mmol / L and 20 mmol / L, and then packed into a 100ml autoclave and reacted for 72h at 150 degrees to obtain a precipitate (Ni 2 Al-LDHs);

[0025] After the reaction kettle is cooled to room temperature, the kettle is opened, and the resulting precipitate is filtered, washed and dried to obtain Ni 2 Al-LDHs solid powder;

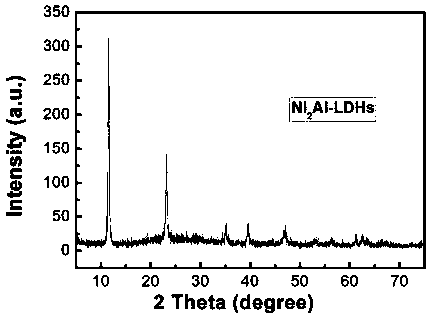

[0026] Ni obtained in embodiment 1 of the present invention 2 The XRD spectrum of Al-LDHs is as follows figure 1 shown;

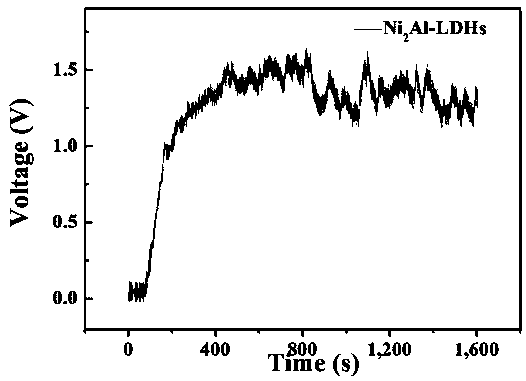

[0027] b. Ni 2 Al...

Embodiment 2

[0032] A water evaporation power generation device based on LDHs of the present invention is the same as that in Embodiment 1.

[0033] The preparation method of the LDHs-based water evaporation power generation device of the present invention is carried out as follows:

[0034] a. Preparation of LDHs solid powder:

[0035] Prepare a mixed solution of 20ml nickel nitrate and aluminum nitrate, wherein Ni 2+ and Al 3+ The concentration is 3.5mol / L, this solution is marked as solution Ⅰ; prepare 200ml of 2.0mol / L NaOH solution, and this solution is marked as solution Ⅱ; prepare 0.1mol / L NaNO 3 Solution 100ml, this solution is marked as solution Ⅲ;

[0036] Put solution Ⅲ into a 1000ml large beaker, then add solution Ⅰ and solution Ⅱ into the beaker drop by drop with a peristaltic pump, and keep stirring with a magnet, monitor the pH of the solution in the beaker with a pH meter, and adjust the two peristaltic pumps The dropping speed keeps the pH of the solution in the beaker...

Embodiment 3

[0044] A water evaporation power generation device based on LDHs of the present invention is the same as that in Embodiment 1.

[0045] The preparation method of the LDHs-based water evaporation power generation device of the present invention is carried out as follows:

[0046] a. Preparation of LDHs solid powder:

[0047] Prepare 80ml of mixed solution of nickel chloride, aluminum chloride and urea, wherein Ni 2+ 、Al 3+ The concentrations of urea and urea were 64 mmol / L, 64 mmol / L and 140 mmol / L, respectively, and then put into a 100ml high-pressure reactor and reacted at 300 degrees for 24 hours to obtain precipitates (NiAl-LDHs);

[0048] After the reaction kettle is cooled to room temperature, the kettle is opened, and the formed precipitate is filtered, washed and dried to obtain NiAl-LDHs solid powder;

[0049] b. Uniformly disperse NiAl-LDHs solid powder in a solvent to form NiAl-LDHs liquid;

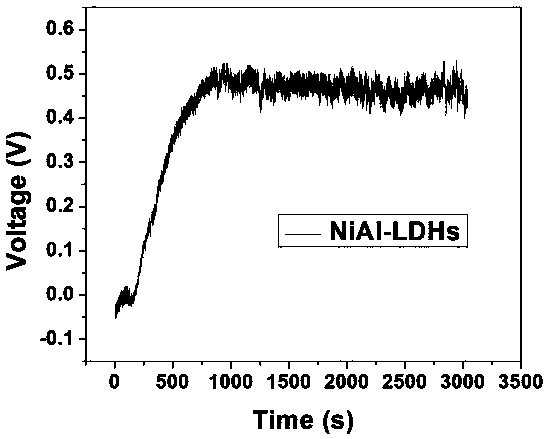

[0050] c. Coating the NiAl-LDHs liquid on the quartz glass sheet equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com