Hydraulic clamping hand for bottle cap

A hydraulic and gripping technology, applied in the direction of flanged bottle caps, etc., can solve the problems of not being able to increase the effective contact surface, decrease the stability of assembly accuracy, and large gaps in bottle cap sizes, so as to increase the effective contact surface, match The effect of improving the installation accuracy and extending the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

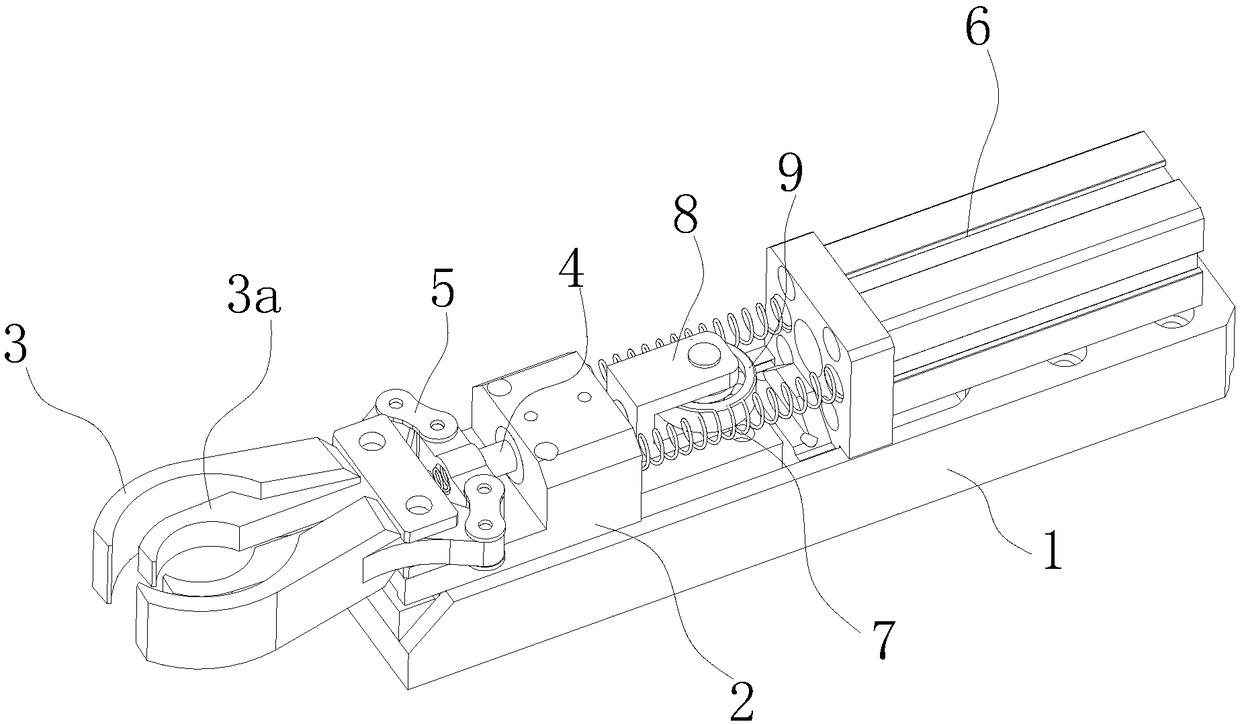

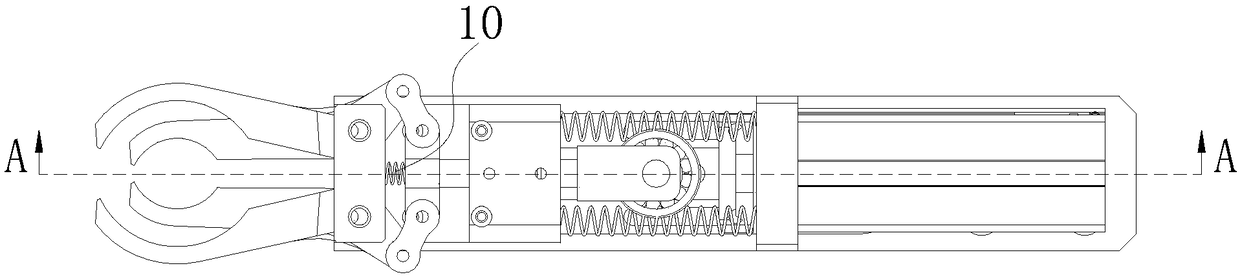

[0020] Such as Figure 1 to Figure 4 As shown, a hydraulic gripper for bottle caps includes a support plate 1, a moving block 2 that slides with the support plate 1, a symmetrically distributed jaw 3 that is hinged on the moving block 2, and a sliding fit with the moving block 2. The guide rod 4, one end is hinged on the guide rod 4 and the connecting plate 5 whose other end is hinged on the jaw 3, the hydraulic cylinder 6 that pushes the guide rod 4 to move during the elongation process, one end is connected to the moving block 2 and the other One end is connected to the spring 7 on the hydraulic cylinder 6.

[0021] The clamping jaws 3 are in an arc-shaped structure bent close to each other, and the clamping jaws 3 are connected with a tightening plate 3 a in the same bending directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com