Optimization method and system of collaborative operating of multiple common-rail unmanned running vehicles of steel coil post-rolling storehouse area

A technology for job optimization and pedestrian traffic, which is applied in general control systems, control/regulation systems, forecasting, etc., and can solve problems such as lack of job optimization methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present invention provides an optimization system for multi-unmanned driving cooperative operation of the common rail in the steel coil rolling warehouse. From the perspective of reasonably assigning driving operation tasks, the system proposes to use artificial intelligence modules to schedule multi-driving cooperative operation optimization calculations, and considers the implementation of collaborative operations. And risk avoidance, so that the multi-travel operation is operated according to the optimized operation sequence, and the optimization effect of the multi-travel operation is achieved.

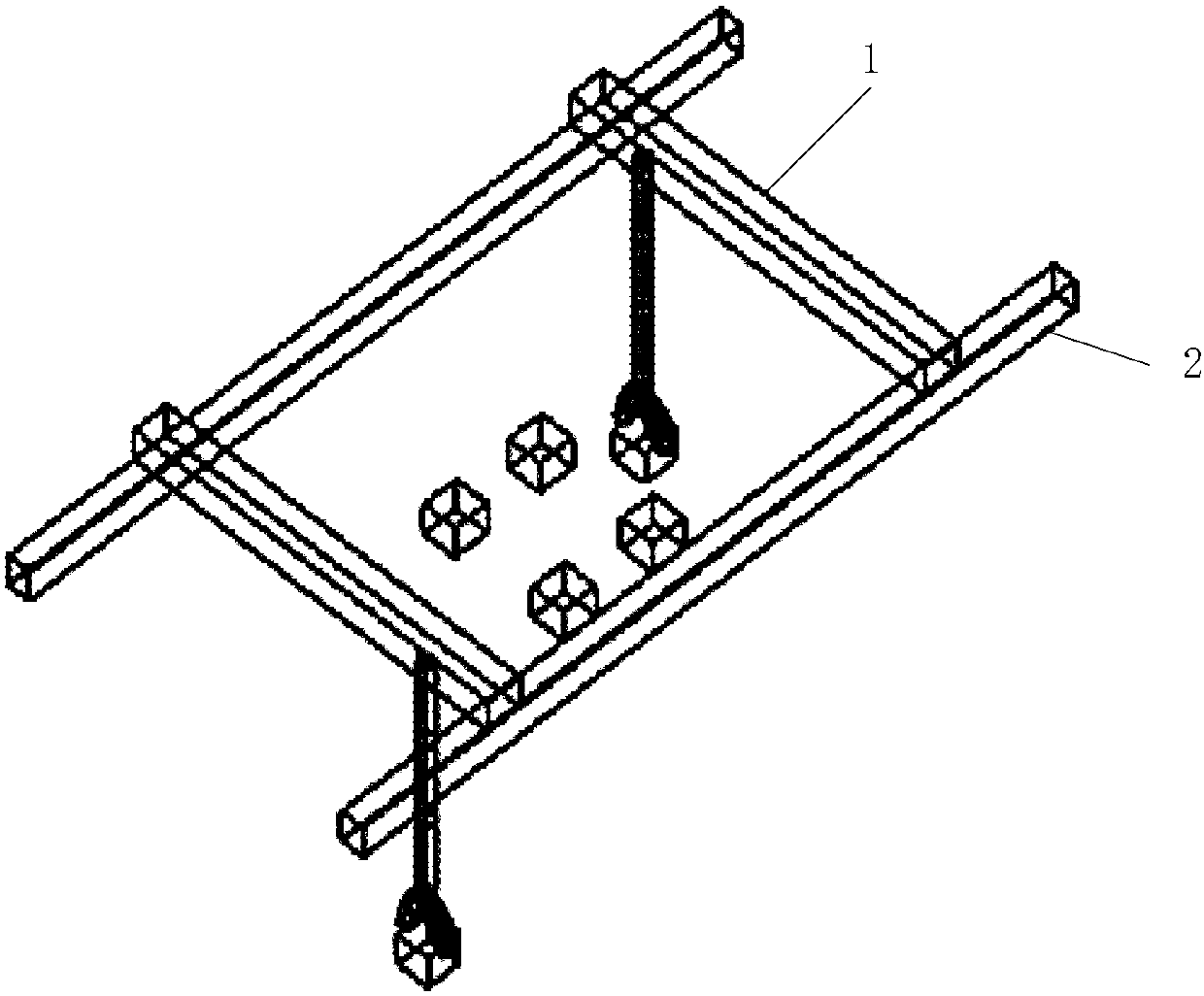

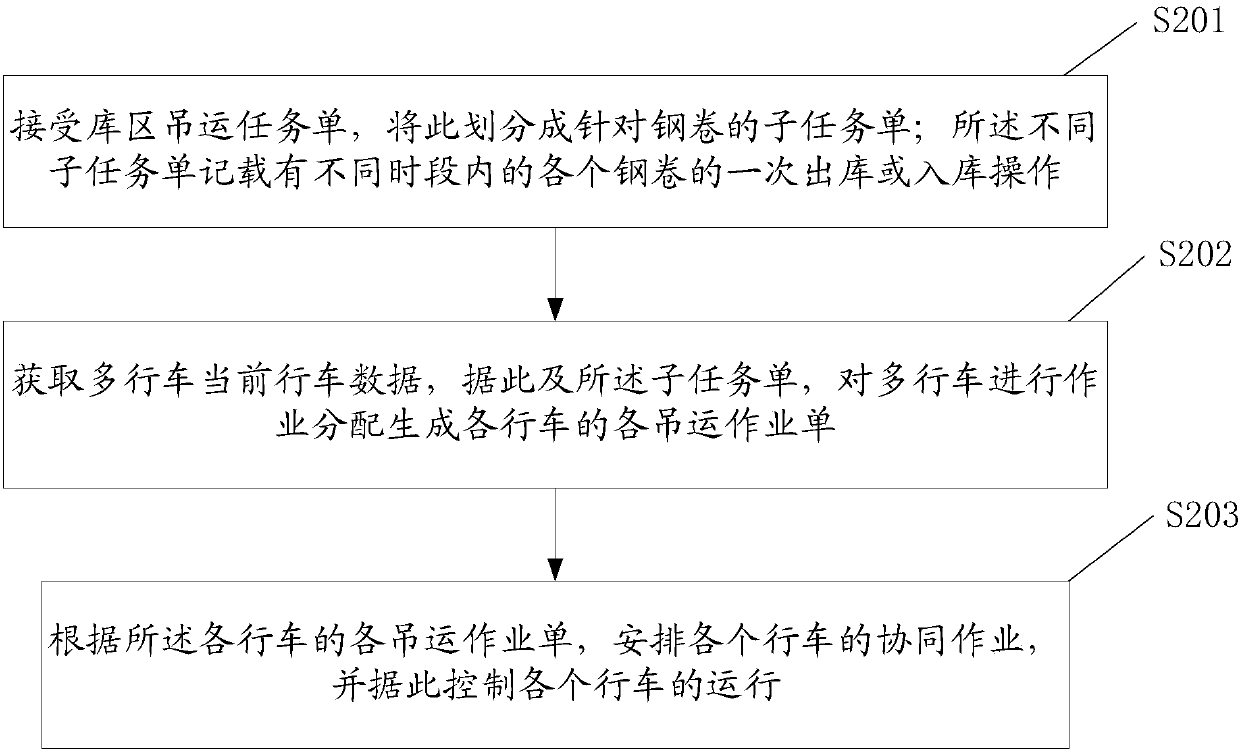

[0042] The following is a further description of the method for optimizing the cooperative operation of common-rail multi-unmanned driving vehicles of the present invention in conjunction with the accompanying drawings and embodiments. Such as figure 1 As shown, it is a schematic diagram of the rolling of the steel coils in the present invention, where many unmanned veh...

Embodiment 2

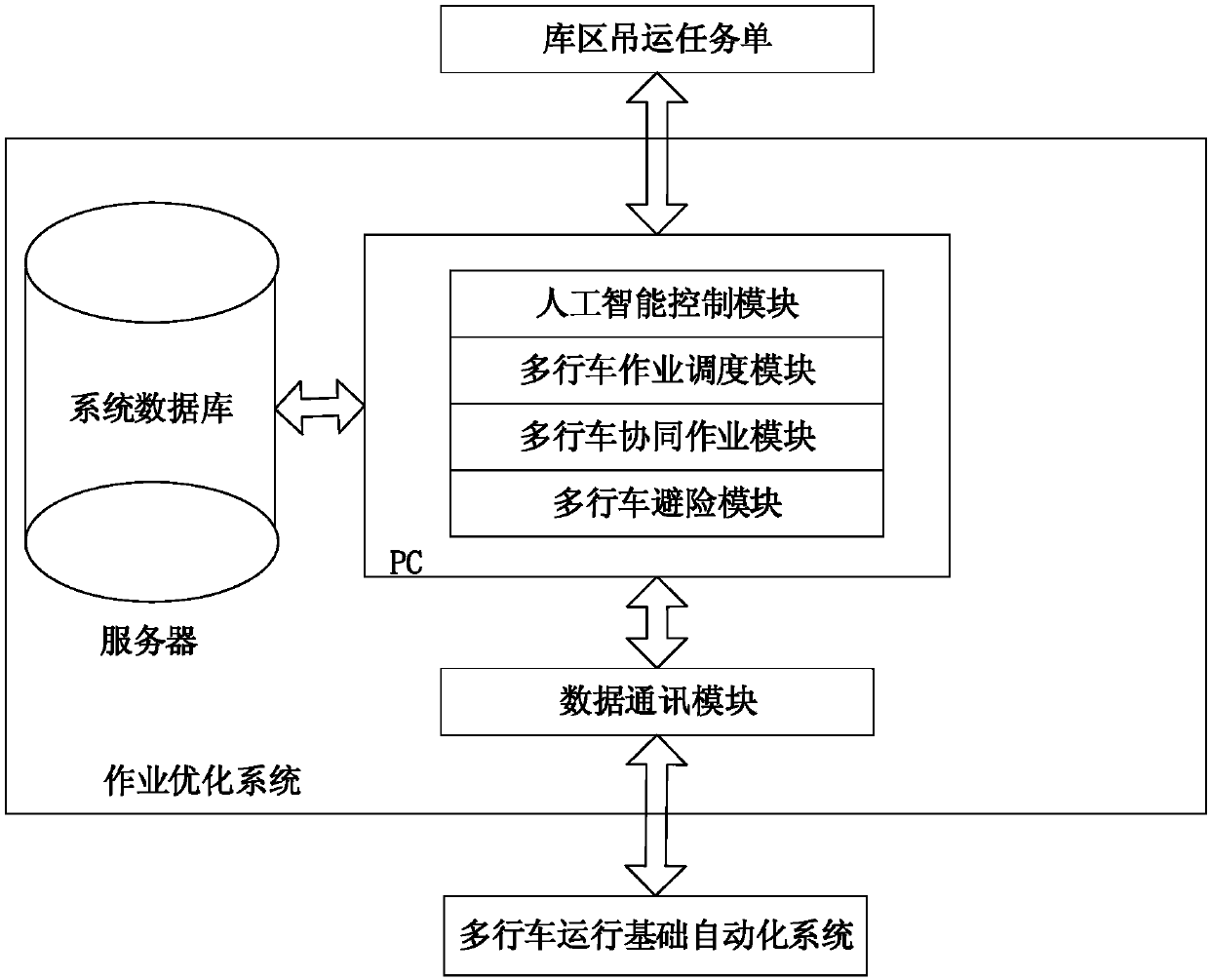

[0079] Based on the above-mentioned optimization method for multi-unmanned driving vehicle collaborative operation of the common rail warehouse after steel coil rolling, this application also provides an optimization system for common rail unmanned driving vehicle collaborative operation of the steel coil rolling warehouse. The system includes:

[0080] System database, artificial intelligence control module, multi-travel operation scheduling module, multi-travel collaborative operation module, basic automation module for traffic operation, and a data communication module connected with the above-mentioned modules for mutual communication;

[0081] Wherein, the system database is used to store multi-travel related data; the artificial intelligence control module is used to provide the warehouse area lifting task list, multi-travel current traffic data and multi-travel related data obtained from the system database to the multi-travel The traffic operation scheduling module is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com