Microreactor based on liquid micrometer motors, preparation method and application thereof

A micro-motor and micro-reactor technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, and analysis by causing chemical reactions to occur in materials, etc. It can solve the problems of complex construction method of the device, and achieve the effect of small size, simple preparation method and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

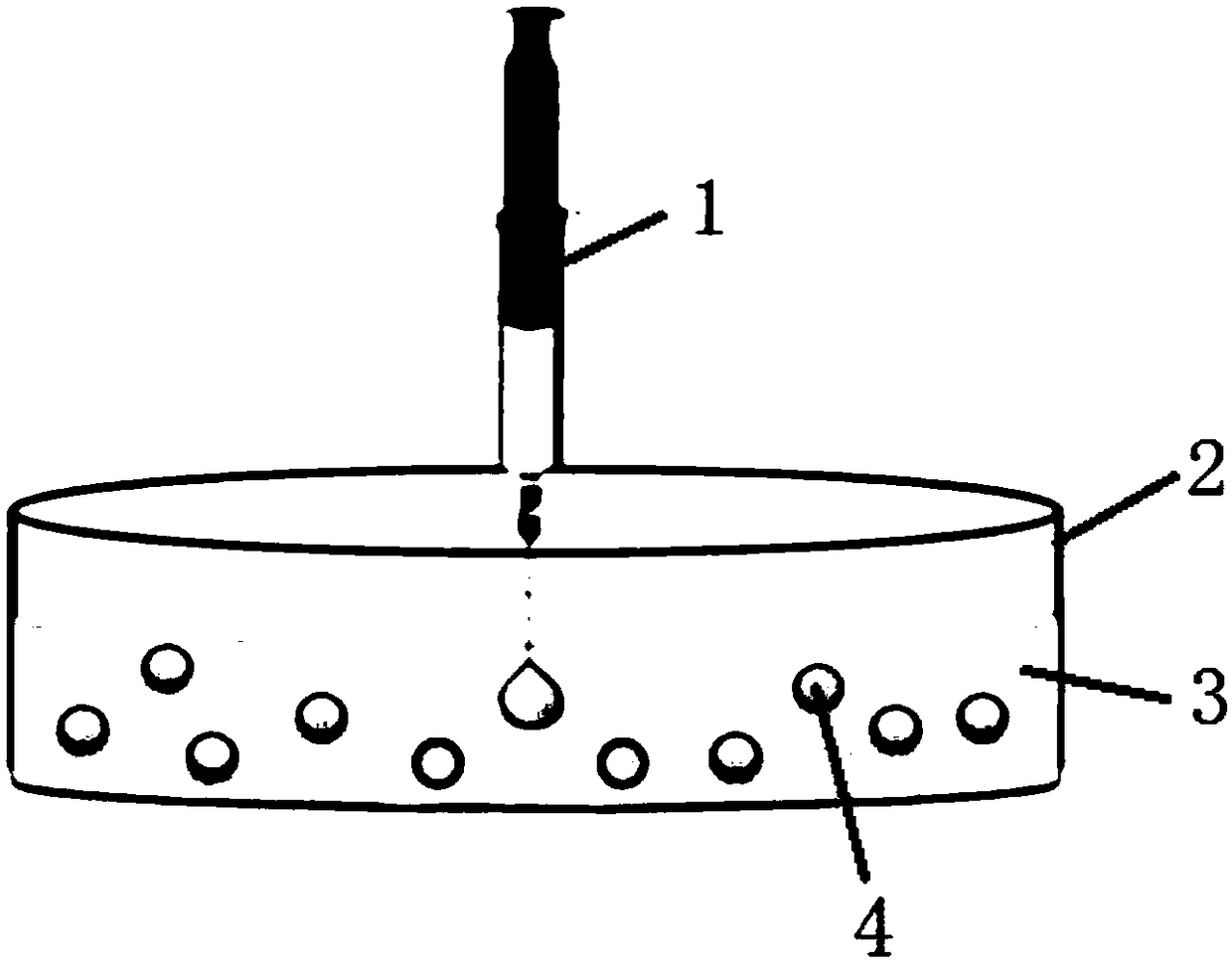

[0054] see figure 1 , Dissolve 3.52mg of spiropyran in 10mL of chloroform to obtain a chloroform solution, wherein the structural formula of spiropyran is (1',3'-dihydro-8-methoxy-1',3',3'-trimethyl-6-nitrospiro[2H-1-benzopyran-2,2'-( 2H)-indole]).

[0055] Then take 1 mL of the chloroform solution of spiropyran prepared above and mix with 9 mL of silicone oil to prepare the silicone oil solution 3 of spiropyran.

[0056] Take 5 mL of the silicon oil solution 3 of spiropyran into the transparent Petri dish 2, and use a micro-syringe 1 to inject the serum aqueous solution and Fehling's reagent (containing sodium hydroxide, copper sulfate and potassium sodium tartrate) into the silicone oil solution respectively. The distance between the two is about 1.5mm, and two micromotors 4 (serum motor and Fehling reagent motor) with a particle diameter of about 300 μm are obtained to form a microreactor.

[0057] Among them, serum aqueous solutions containing different concentrations...

Embodiment 2

[0065] Dissolve 3.5mg of spiropyran in 10mL of chloroform to obtain a chloroform solution, wherein the structural formula of spiropyran is

[0066] Then, 1 mL of the chloroform solution of spiropyran prepared above was mixed with 9 mL of silicone oil to prepare a solution of spiropyran in silicone oil.

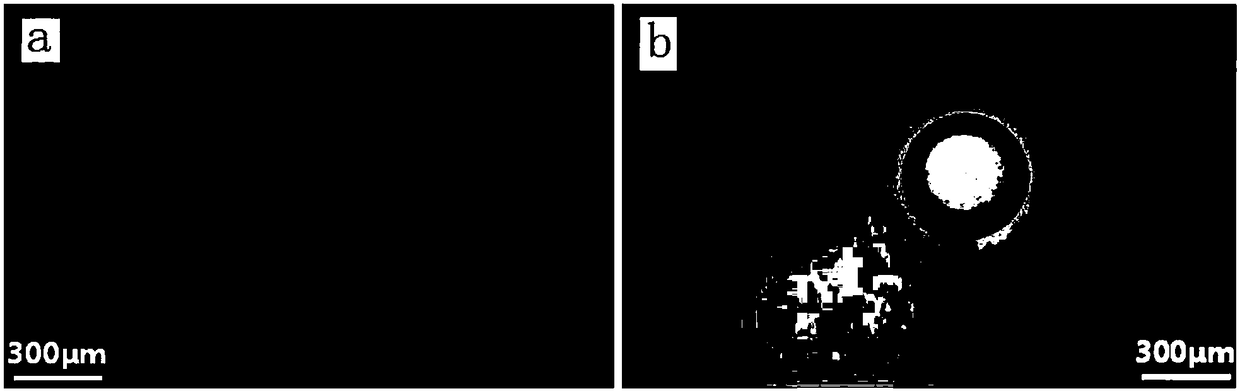

[0067] Take 5mL of spiropyran silicone oil solution into a transparent Petri dish, and use a micro-syringe to inject FeCl 3 The aqueous solution of NaOH and the aqueous solution of NaOH were injected into different positions in the silicone oil solution to obtain two micron motors (FeCl 3 motor and NaOH motor), forming a microreactor.

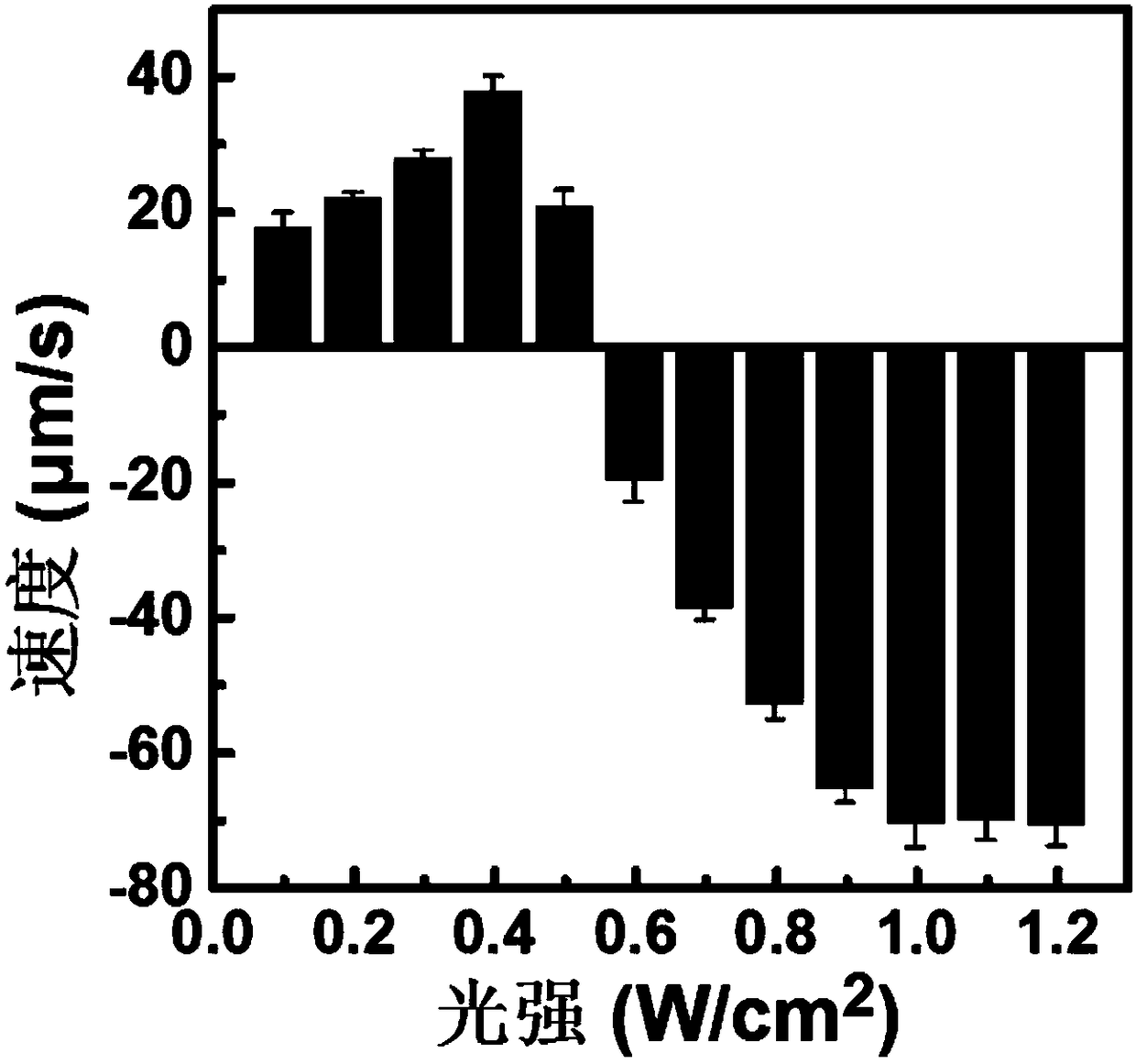

[0068] Using the above microreactor for FeCl 3 The reaction between the motor and the NaOH motor uses a white light source, which is formed by mixing light of 371nm, 409nm, 442nm, 554nm, and 582nm, and the light intensity is 0.7W / cm 2 , the specific operation is as follows:

[0069] The white light source is irradiated perpendicular to th...

Embodiment 3

[0072] 4.4mg spiropyran is dissolved in 10mL dichloromethane solvent, obtains dichloromethane solution, wherein the structural formula of spiropyran is (where R=C 8 h 17 ).

[0073] Then, 1 mL of the chloroform solution of spiropyran prepared above was mixed with 9 mL of silicone oil to prepare a solution of spiropyran in silicone oil.

[0074] Take 3mL of the silicon oil solution of spiropyran into a transparent Petri dish, and use a micro-syringe to inject KSCN and FeCl respectively 3 Injected into different positions in the silicone oil solution, two micromotors with a particle size of about 200 μm were obtained to form a microreactor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com