Quickly-opened embrasure

A shooting hole and opening technology, which is applied in armor, offensive equipment, protective equipment, etc., can solve the problems of unlimited positions, cumbersome operation, inconvenient push and pull, etc., and achieve the effect of simple and novel structure, simple assembly process, safe and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

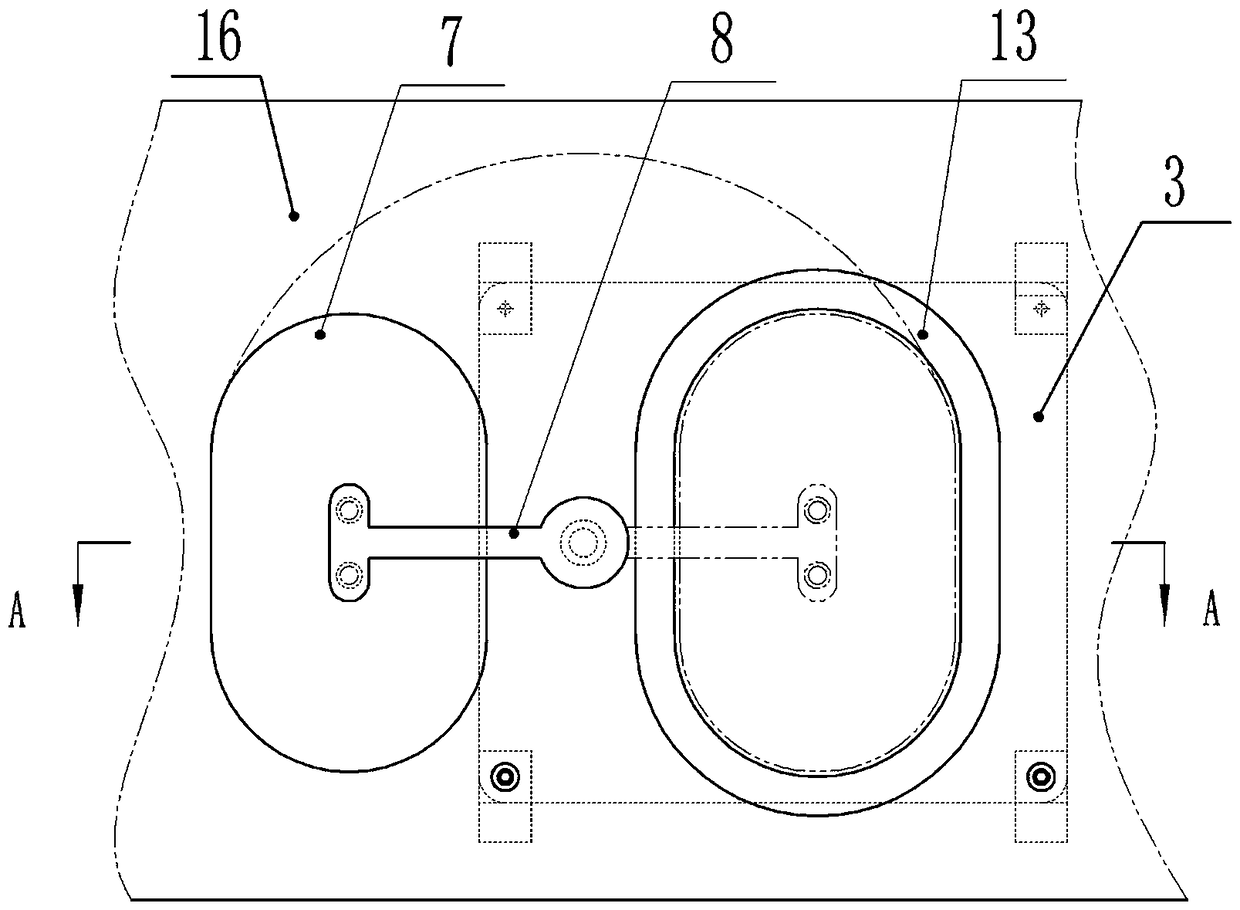

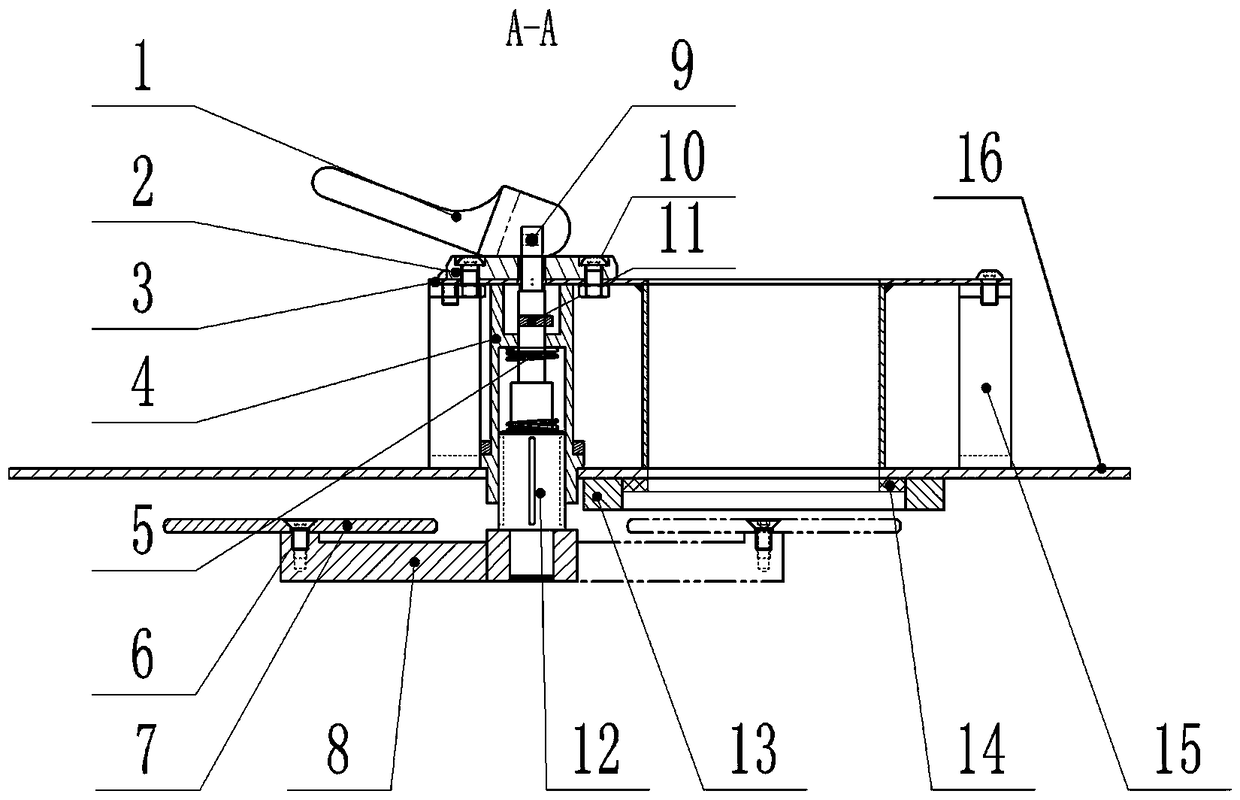

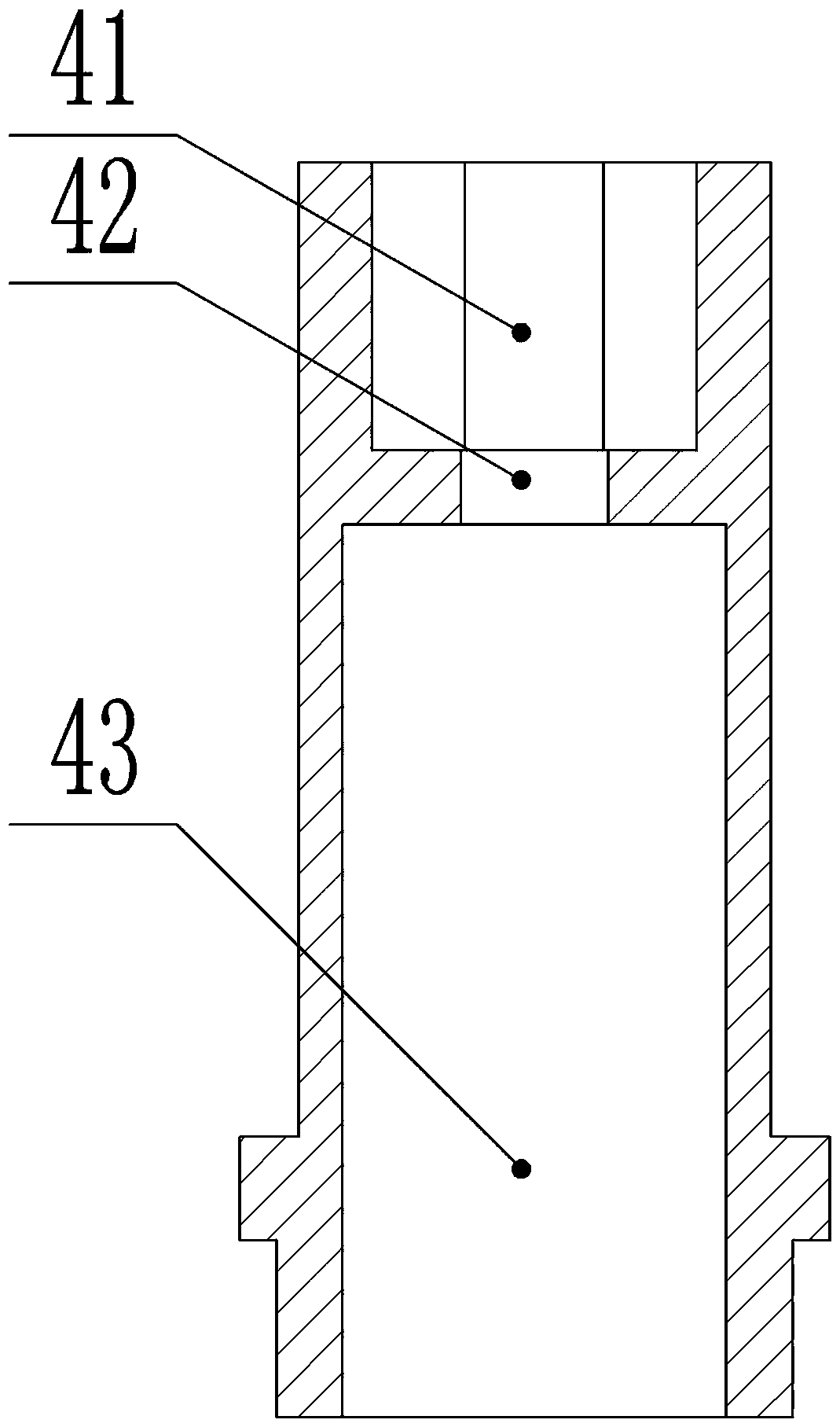

[0022] Embodiment 1: In this embodiment, if Figure 1-7 As shown, a quick-opening shooting hole includes a bulletproof steel plate, a guide limit bushing, and an external limit groove. The bulletproof steel plate is provided with an opening hole and a shooting hole, and the guide limit bushing is welded and fixed on the bulletproof In the open hole on the steel plate, the inside of the guide limit bushing is movably connected to the rotating shaft, and the rotating shaft extends out of the outer end face of the guide limit bushing to weld one side of the connecting piece, and the other side of the connecting piece is connected by a grub screw A movable baffle is connected, and the outer limiting groove is welded and fixed on the outside of the bulletproof steel plate. The outer limiting groove is a hollow cylinder, and the through hole in the middle of the outer limiting groove is aligned with the shooting hole. The movable baffle and the The through hole in the middle part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com