Waist-hung inside-clothes air blowing cooling device for high temperature operation

A technology of high-temperature operation and internal blowing, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., and can solve the problems of employees lacking cooling and dehumidification devices in clothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to more clearly illustrate the technical content, structural features, objectives and effects of the present invention, further detailed description will be given below in conjunction with the embodiments and accompanying drawings.

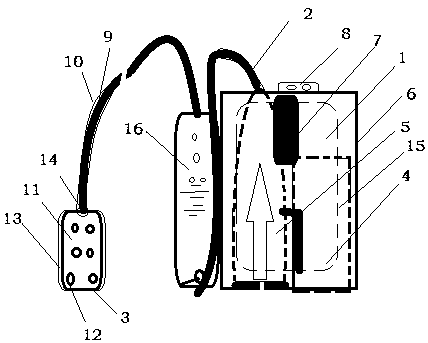

[0020] Such as figure 1 As shown in the figure, the waist-hanging clothes blowing cooler for high-temperature operation includes a blowing device 1, the blowing device 1 is connected to an air filter 16, the air filter 16 is connected to an air transmission line 2, and the air transmission line 2 is connected to an air diffuser 3 .

[0021] Described blowing device 1 is made up of battery 4, small and micro blower 5, plastic case 6, hanging nose 7, intensity switch 8, LED electronic screen 15, air filter 16; Inside the shell 6, a hanging nose 7 is placed on one side of the plastic shell 6, which is hung on the belt during use, and the strength switch 8 is manually controlled, and the small and micro blower 5 is braked so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com