A foaming agent

A foaming agent and material technology, applied in the field of foaming agent, can solve the problems of physical injury of operators, strong irritating odor, large amount of foaming agent, etc., and achieve environmental protection, increase foam strength, and foam layer stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Take: 30% cyclohexanol, 15% cyclohexanone, 25% diethyl adipate, and 4-methyl-3-pentenone-[2] 30%.

[0009] All the percentages of the above materials are percentages by weight. The above materials are physically mixed, and the prepared medicament is a brown liquid, clear and transparent, no stratification, no precipitation, no suspended matter, chemical stability, storage in a cool and ventilated place, long-term No quality changes.

[0010] The flotation experiment of rare earth is carried out on the strong magnetic medium ore after the weak magnetic-strong magnetic separation of the medium-poor oxide ore from Baiyun Obo, Inner Mongolia by using this reagent and the rare-earth collector. The mineral contains 8.35% fluorine bastrite and lives alone. Stone 3.37%, fluorite 17.08%, hematite, feldspar, mica, sodium limestone, sodium amphibolite, etc.

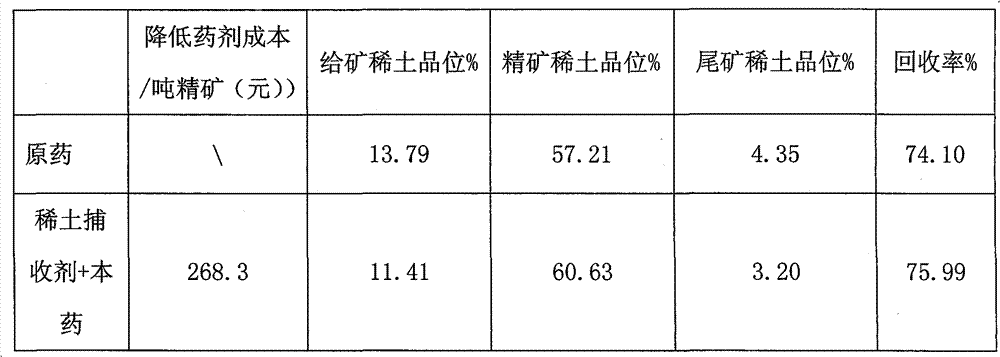

[0011] The experiment was carried out under the premise of the original process flow and the slurry concentration of the grinding...

Embodiment 2

[0016] The foaming agent contains: cyclohexanol 35%, cyclohexanone 20%, diethyl adipate 17%, 4-methyl-3-pentenone-[2] 28%.

[0017] The percentages of materials are all percentages by weight. The above materials are physically mixed, and the medicament prepared by the present invention is a brown liquid, clear and transparent, without stratification, no precipitation, no suspended matter, stable chemical properties, and stored in a cool and ventilated place for a long time. Quality changes.

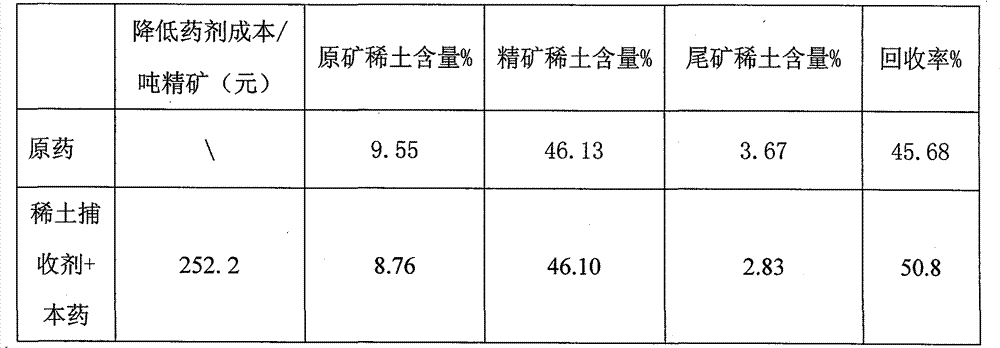

[0018] The experiment was conducted on the rare earth ore in Damao Banner, Inner Mongolia by using this drug in combination with a rare earth collector. The ore contained REO (REO) with a high impurity content of 8.76%, making it difficult to sort.

[0019] Experimental results:

[0020]

[0021] The experimental results show that for the original ore of Damao rare earths, the combination of this reagent and the rare earth collector for the original reagent has low cost and significantly improved...

Embodiment 3

[0023] The foaming agent contains: 25% cyclohexanol, 20% cyclohexanone, 15% diethyl adipate, and 4-methyl-3-pentenone-[2] 30%.

[0024] All percentages are percentages by weight. The above materials are physically mixed. The medicament prepared by the present invention is a brown liquid, clear and transparent, no stratification, no precipitation, no suspended matter, stable chemical properties, and stored in a cool and ventilated place for a long time. Quality changes.

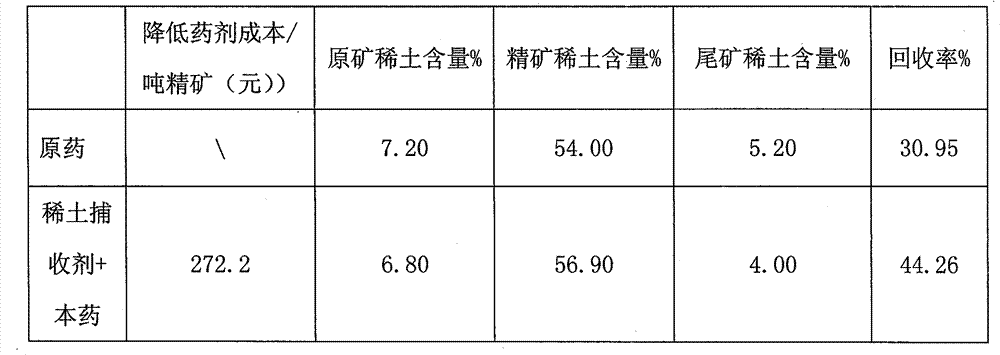

[0025] Using this agent with rare earth collectors, the raw materials come from the total tailings of Baotou Steel, with complex mineral components, including fluorite, apatite, non-magnetic iron minerals, mica, pyroxene, amphibole, etc., as well as wastewater from rare earth smelting , Waste residue.

[0026] The experiment was carried out without changing the on-site process flow, grinding fineness, and slurry concentration. Using jet flotation equipment, one-time separation process, compared with the original rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com