Plastic cop latch and sewing machine cop latch suite

A bobbin and plastic technology, applied in the field of sewing parts, can solve the problems of affecting the quality of brakes, easy wear and heavy weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

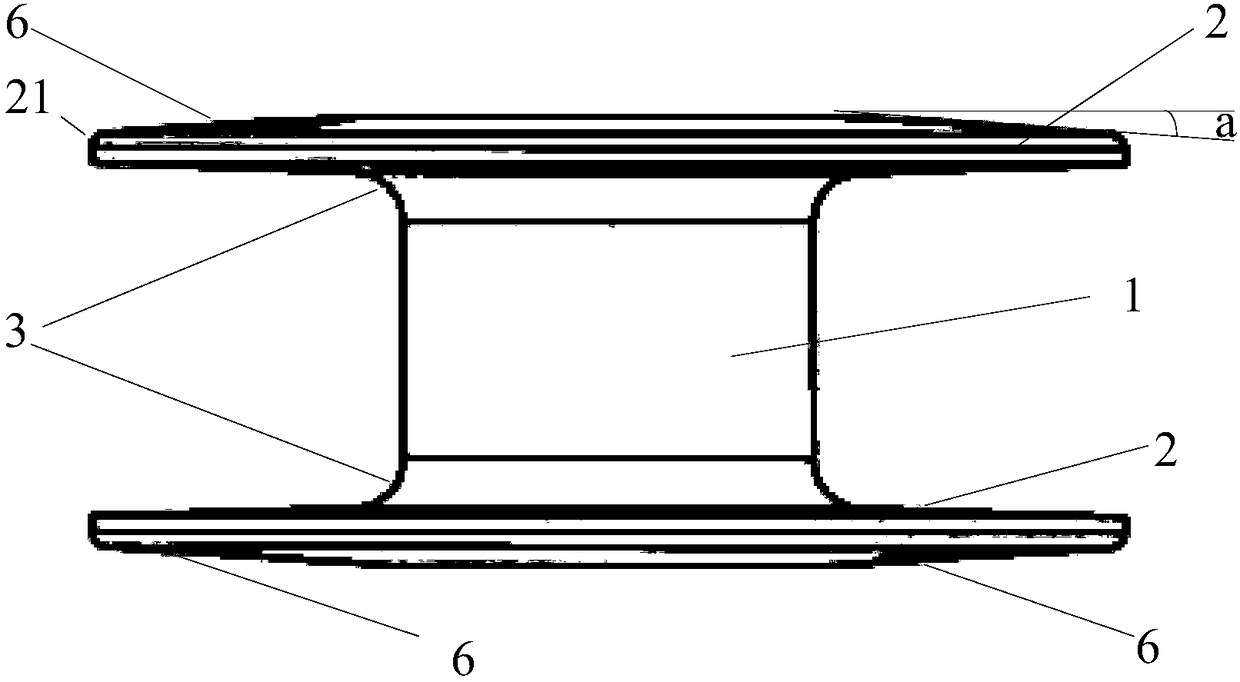

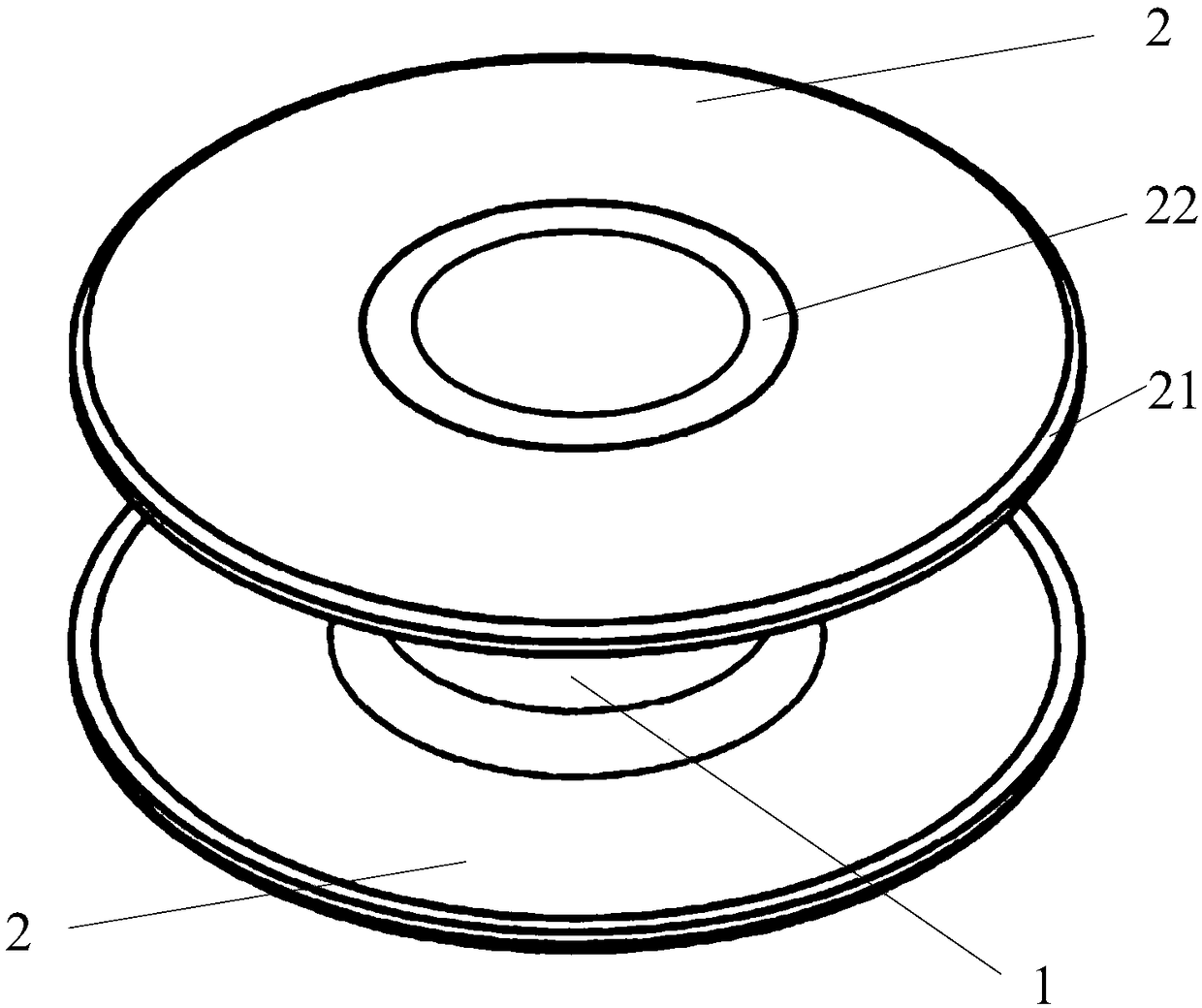

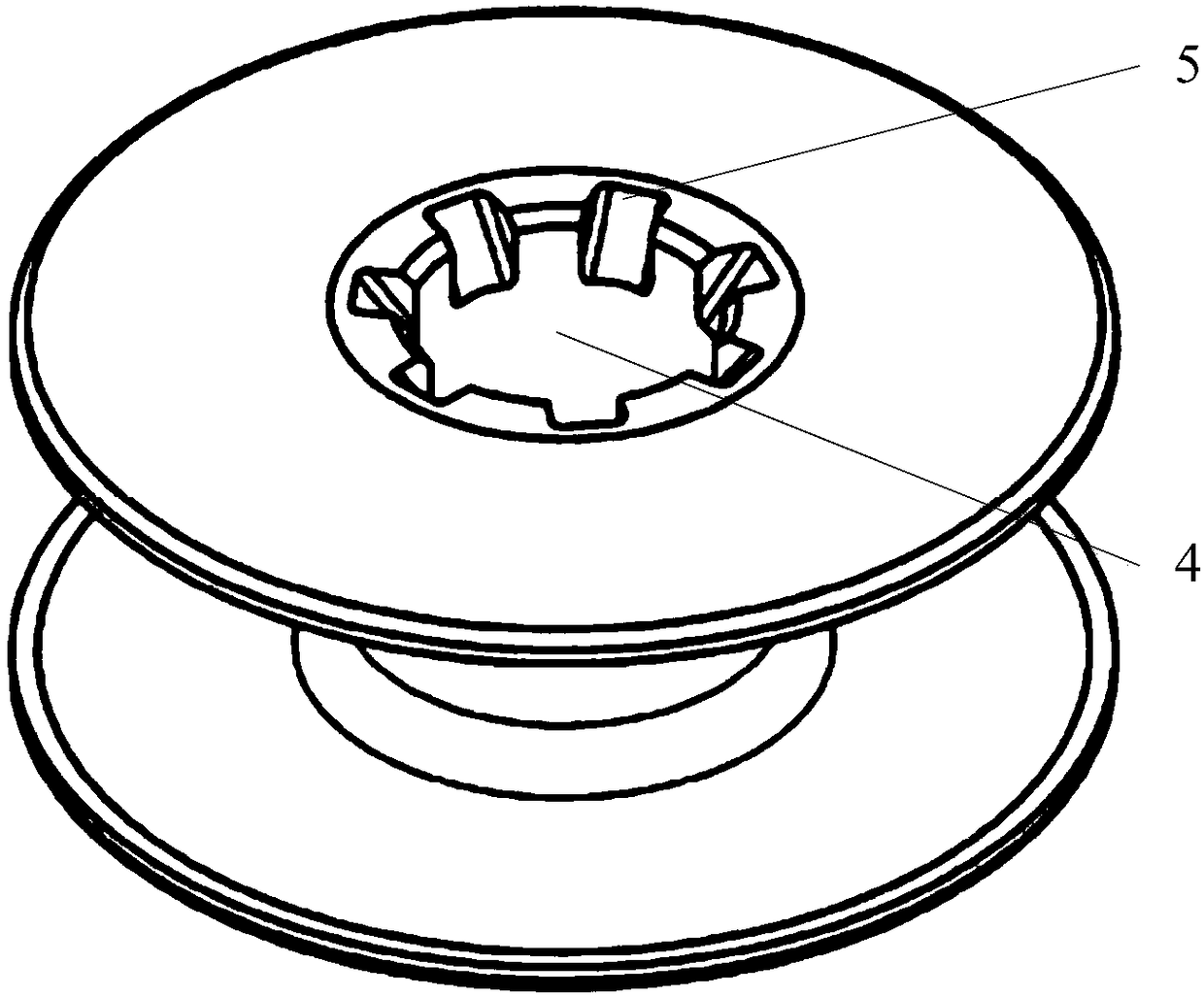

[0025] The embodiment of the present invention provides a kind of plastic bobbin, with reference to Figure 1-2 As shown, it includes: a bobbin 1 and flanges 2 that are respectively arranged at both ends of the bobbin 1 and extend radially outward; the bobbin 1 is barrel-shaped, and the two ends of the bobbin are arranged There is a shaft hole; one of the two flanges 2 is called the first flange, and the other is called the second flange; the side of the two flanges 2 away from the winding shaft 1 is circular; the above-mentioned winding shaft, the second The first flange and the second flange are both made of engineering plastics and integrally formed. The section of the bobbin 1 and the flange 2 along the axial di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com