Underground coal mine while drilling collapse prevention flushing fluid and preparation method thereof

A flushing fluid and anti-collapse technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of easy collapse of the hole wall, limited slag discharge capacity of flushing fluid, etc. The effect of degradation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation approach 1

[0025] Indoor experiment of anti-slump flushing fluid while drilling: Add 1.5g of main viscosity-increasing agent, 2.0g of auxiliary viscosity-increasing agent, and 2.5g of flocculant in 500ml of clean water, stir thoroughly for 0.5 hours, and let stand for 12 hours to obtain anti-slump while drilling Type rinse fluid base fluid. Add 20g of bentonite to the base liquid and stir evenly to obtain the anti-collapse flushing liquid while drilling.

preparation approach 2

[0027] Indoor experiment of anti-slump flushing fluid while drilling: add 1.0g of main viscosity-increasing agent, 1.5g of auxiliary viscosity-increasing agent, and 2.0g of flocculant in 500ml of clean water, stir thoroughly for 0.5 hours, and let stand for 12 hours to obtain anti-slump while drilling Type rinse fluid base fluid. Add 25g of bentonite to the base liquid and stir evenly to obtain the anti-collapse flushing liquid while drilling.

preparation approach 3

[0029] Indoor experiment of anti-slump flushing fluid while drilling: Add 2.0g of main viscosity-increasing agent, 2.0g of auxiliary viscosity-increasing agent, and 1.0g of flocculant in 500ml of clean water, stir thoroughly for 0.5 hours, and let stand for 12 hours to obtain anti-slump while drilling Type rinse fluid base fluid. Add 25g of bentonite to the base liquid and stir evenly to obtain the anti-collapse flushing liquid while drilling.

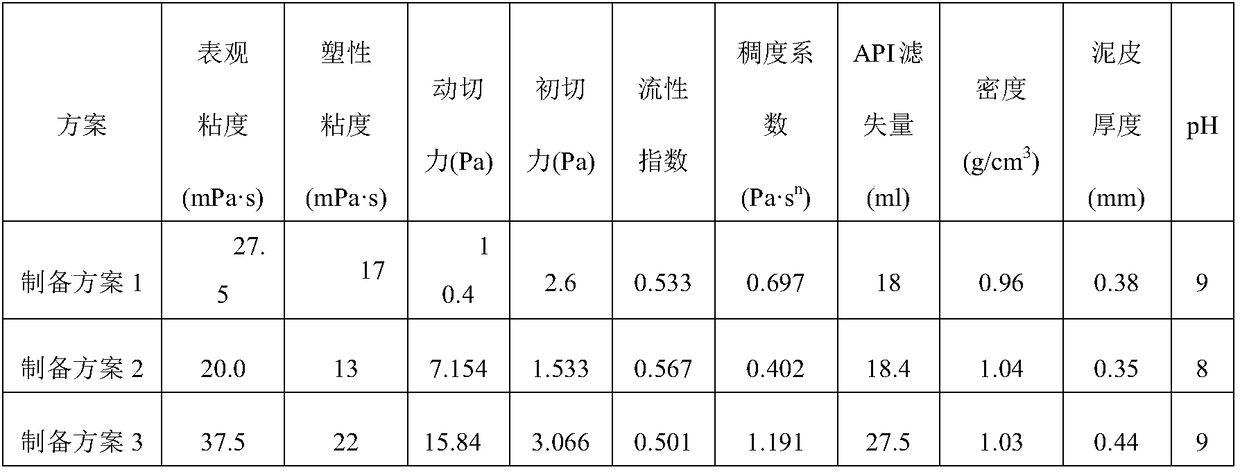

[0030] On the basis of completing three different preparation schemes, various basic performance tests and decomposition performance tests were carried out on the prepared anti-collapse flushing fluid while drilling. The fully preferred formulation is, in terms of mass fraction: 4% bentonite + 0.3% carboxymethyl cellulose sodium salt + 0.4% Tianqing gum + 0.5% nonionic polyacrylamide.

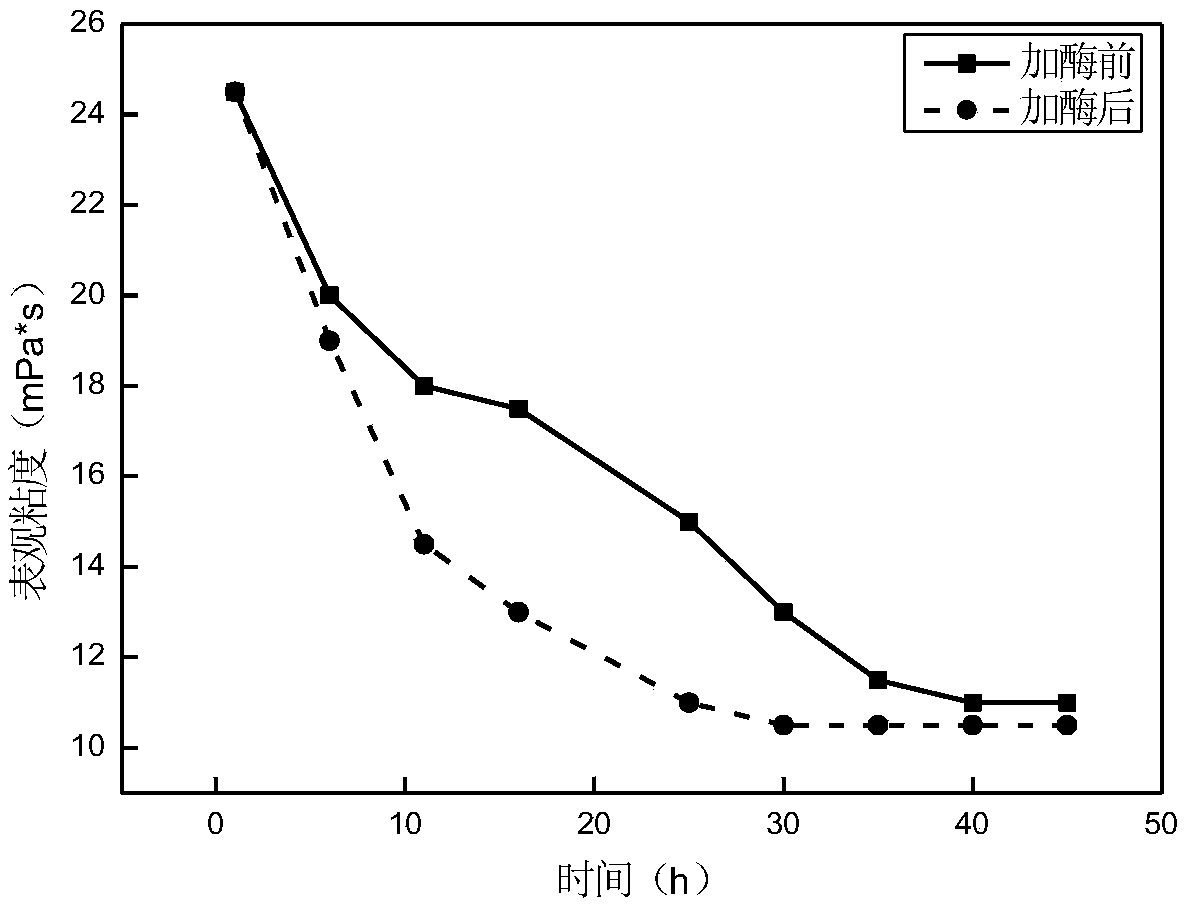

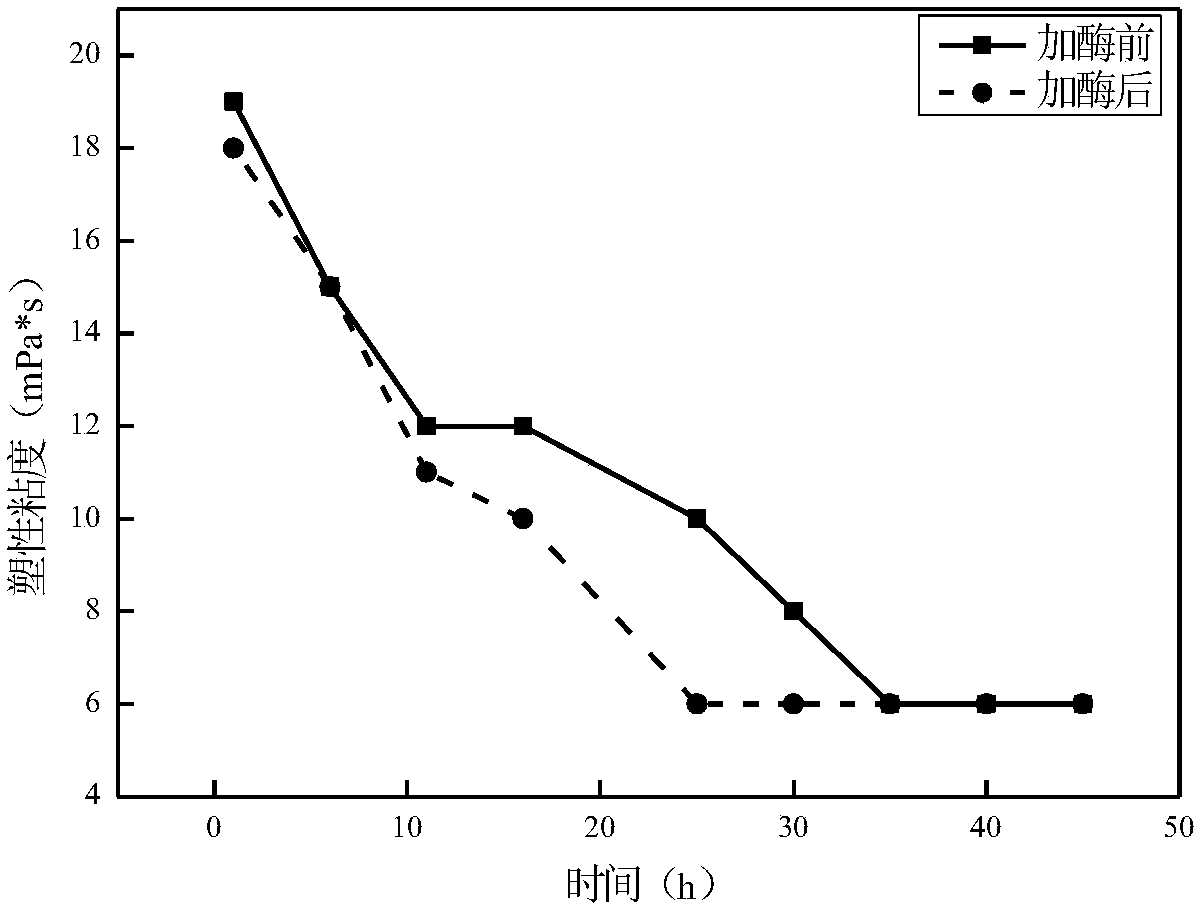

[0031] (1) Basic performance test: mainly includes performance tests such as density, rheology (including apparent viscosity, plastic viscosity, dynam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com