Ultralow-aldehyde impregnating adhesive for impregnated paper and preparation method of ultralow-aldehyde impregnating adhesive

A technology of ultra-low aldehyde and impregnating glue, which is applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., and can solve the problems that the performance of impregnating glue cannot be compatible with each other, prolong the production cycle, and reduce production efficiency. , to achieve the effect of eliminating the addition of formaldehyde removal agent, good surface performance and high water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of melamine-modified ultra-low aldehyde grade urea-formaldehyde resin

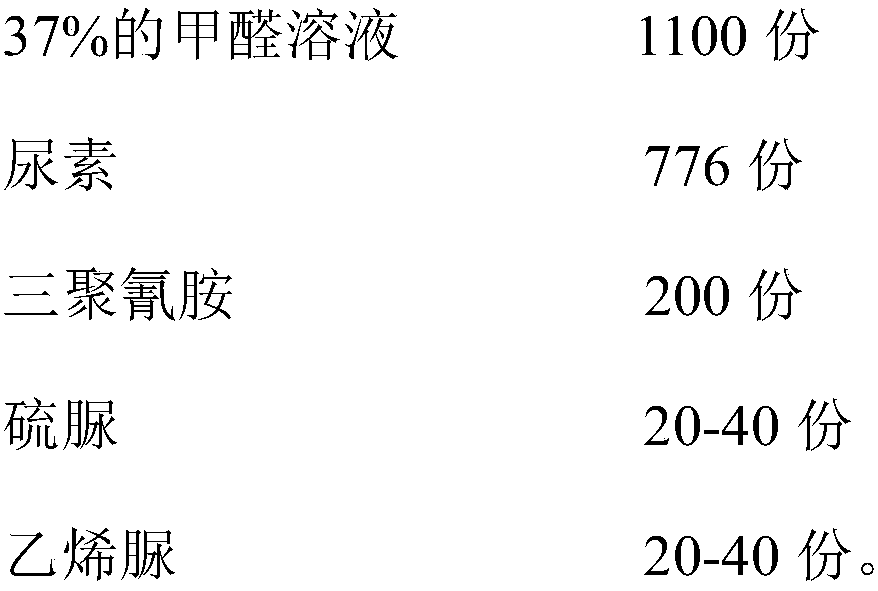

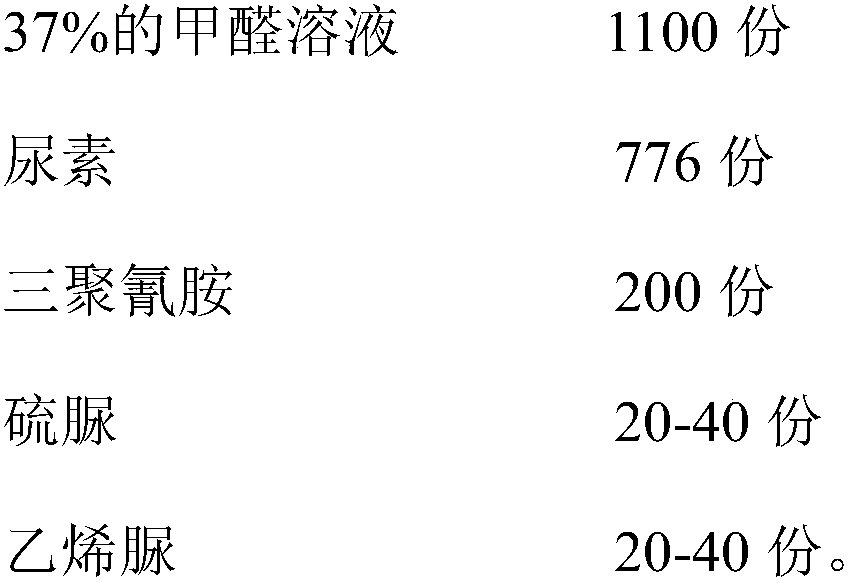

[0032] (1) Material preparation:

[0033] ① Formaldehyde solution: excellent grade, mass fraction 37%, 1100kg;

[0034] ② Urea: industrial grade, first-class product, content ≥ 99%, 776kg (divided into three parts, respectively 402kg, 222kg, 152kg);

[0035] ③ Melamine, industrial grade, high-quality product, content ≥ 99%, 200kg (divided into two parts, 120kg and 80kg respectively);

[0036] ④ Thiourea: industrial grade, superior product, content ≥99%, 20kg;

[0037] ⑥Ethylene urea, industrial grade, superior product, content ≥98%, 20kg;

[0038] ⑦Formic acid solution, industrial grade, superior product, concentration 30% (obtained by diluting the stock solution with 85% concentration), appropriate amount;

[0039] ⑧Sodium hydroxide solution, industrial grade, concentration 30%, appropriate amount;

[0040] Remarks: The amounts of the above components are parts by weight; in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com