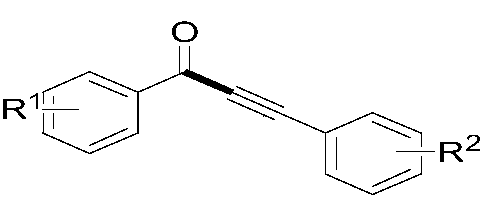

Preparation method of 1, 3-diarylpropargyl ketone

A technology for diarylpropynone and alkynoic acid, which is applied in the field of preparation of 1,3-diarylpropynone and achieves the effects of good compatibility, mild reaction conditions and simple catalytic system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14

[0033] The α-keto acid (1.1mmol, R 1 =H), aryl alkynoic acid (1mmol, R 2=H), silver catalyst (5mol%) and oxidizing agent (2mmol) were dispersed in the solvent, and then stirred at 50° C. for 3 hours under air atmosphere. After the reaction, with Et 2 O (5 mL) was extracted three times, and the combined organic phases were concentrated under reduced pressure. The obtained crude product was subjected to column chromatography (300-400 mesh silica gel, petroleum ether and ethyl acetate as eluents) to obtain the target product. The silver catalyst, oxidant and solvent used and the reaction results are shown in Table 1.

[0034] The reaction condition and reaction result of table 1 embodiment 1~10

[0035]

[0036]

[0037] a The total volume of solvent was kept at 2 mL.

Embodiment 14~29

[0039] α-keto acid (1.1mmol), aryl alkynoic acid (1mmol, R 2 =H), AgOAc (5mol%) and (NH 4 ) 2 S 2 o 8 (2mmol) dispersed in DMSO (1mL) and H 2 O (1 mL) in a mixed solvent, and then stirred at 50° C. for 3 hours under air atmosphere. After the reaction, with Et 2 O (5 mL) was extracted three times, and the combined organic phases were concentrated under reduced pressure. The obtained crude product was subjected to column chromatography (300-400 mesh silica gel, petroleum ether and ethyl acetate as eluents) to obtain the target product. The substrates used and the reaction results are listed in Table 2.

[0040] The reaction substrate and result used in table 2 embodiment 14~29

[0041]

Embodiment 30~41

[0043] The α-keto acid (1.1mmol, R 1 =H), aryl alkynoic acid (1mmol, R 2 =H), AgOAc (5mol%) and (NH 4 ) 2 S 2 o 8 (2mmol) dispersed in DMSO (1mL) and H 2 O (1 mL) in a mixed solvent, and then stirred at 50° C. for 3 hours under air atmosphere. After the reaction, with Et 2 O (5 mL) was extracted three times, and the combined organic phases were concentrated under reduced pressure. The obtained crude product was subjected to column chromatography (300-400 mesh silica gel, petroleum ether and ethyl acetate as eluents) to obtain the target product. The substrates used and the reaction results are listed in Table 3.

[0044] The reaction substrate and result used in table 3 embodiment 30~41

[0045]

[0046] The characterization data of some products are as follows:

[0047] 1,3-Diphenylprop-2-yn-1-one:White solid. 1 H NMR (400MHz, CDCl 3 )δ8.08(d, J=7.2Hz, 2H), 7.54(d, J=6.8Hz, 2H), 7.50–7.44(m, 1H), 7.38(t, J=7.6Hz, 2H), 7.32( d,J=7.2Hz,1H),7.28–7.26(m,2H). 13 C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com