Processing method for cylindrical turning of arc plate assembly

A processing method and combined car technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as easy deformation, difficult clamping, and unstable workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described in detail below in conjunction with the description of the drawings and specific embodiments.

[0023] refer to figure 1 , a kind of arc-plate combination turning outer circle processing method of the present invention, specifically implement according to the following steps:

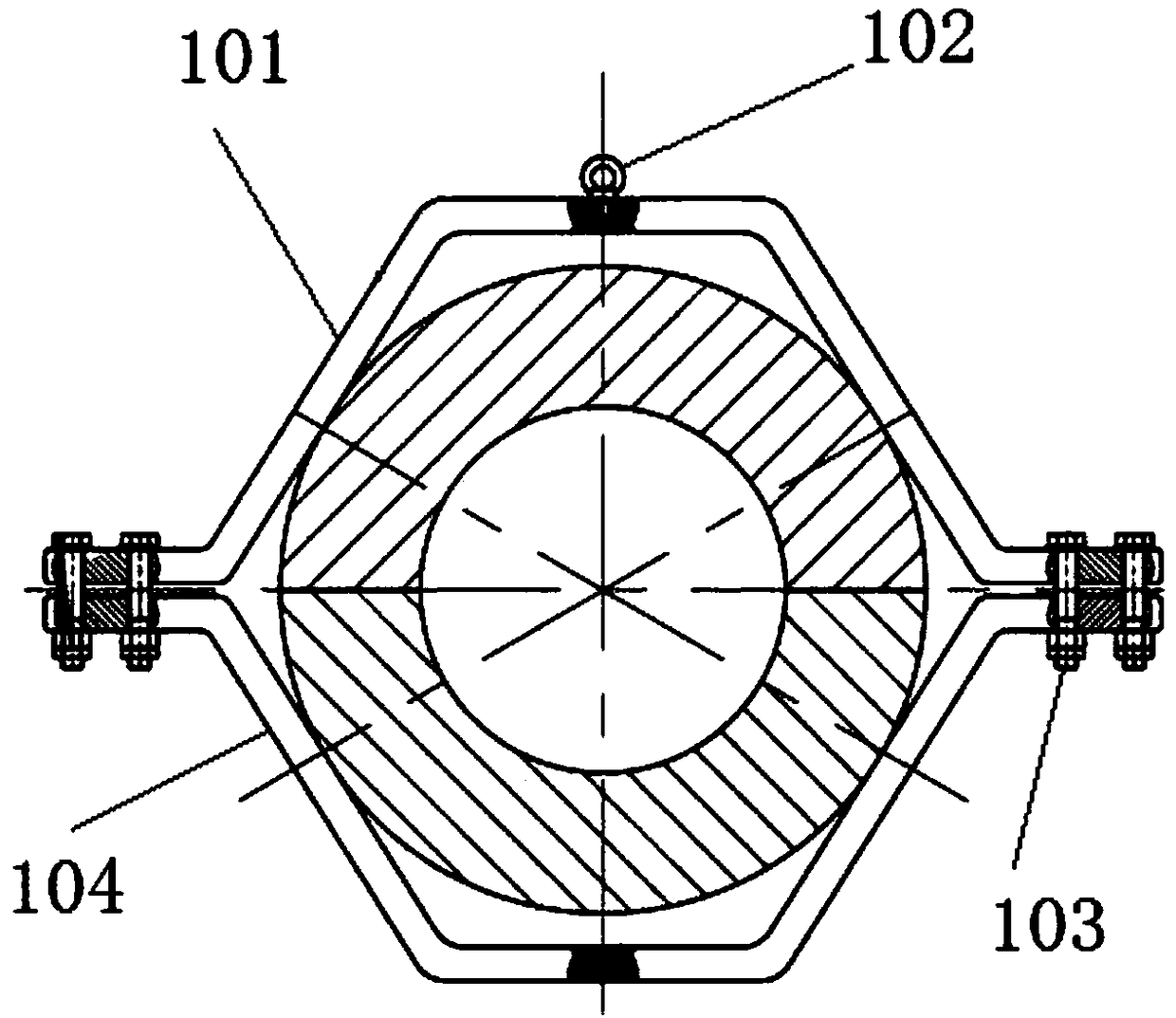

[0024] Firstly, the first clamping position is processed at one end of each arc-shaped plate, and the second clamping position is processed at the other end, and when all the arc-shaped plates are assembled in a cylindrical shape, all the first clamping positions constitute the first a cylindrical end, and all second clamping positions form a second cylindrical end;

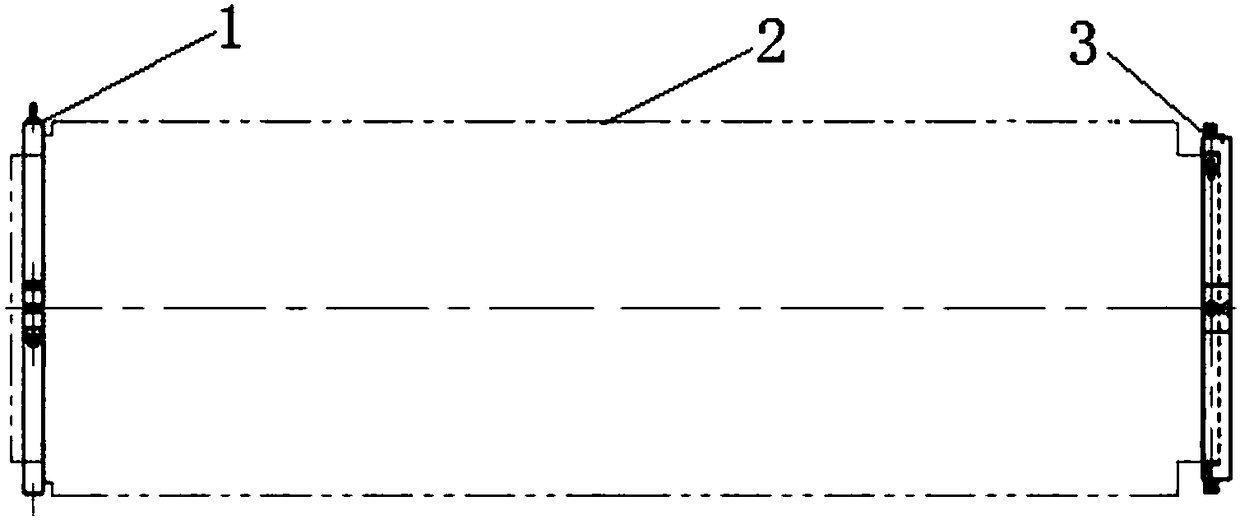

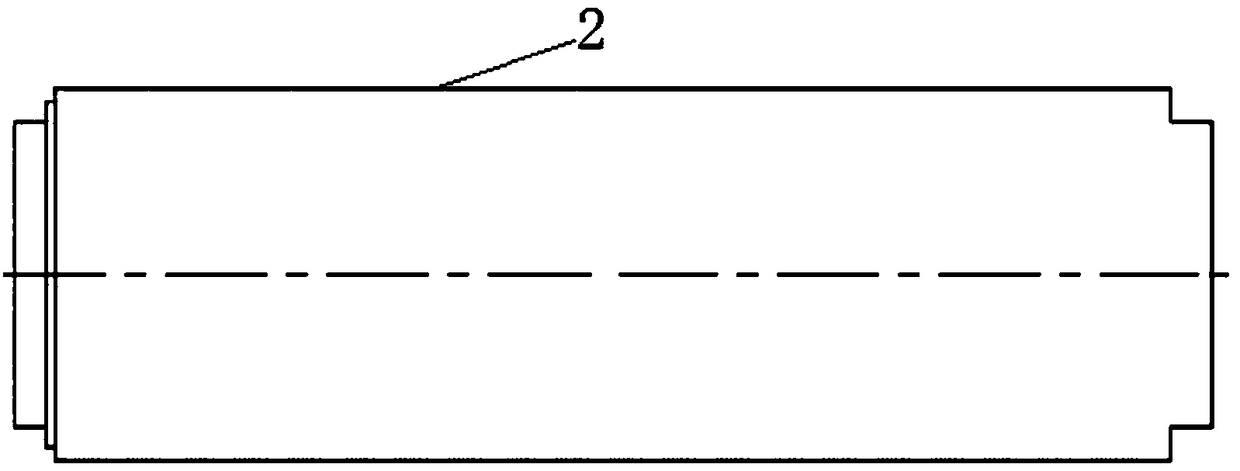

[0025] Secondly, after assembling all the arc-shaped plates in a cylindrical shape to form the assembly 2, use the clamping body 1 to clamp the first cylindrical end, and fasten the second cylindrical end to the blind hole 301 on one side of the top plate 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com