Sand production line waste treatment system

A waste treatment and production line technology, applied in construction waste recycling, solid waste removal, and use of liquid separators, etc., can solve the problems of inability to reuse waste and poor air quality, reduce engineering construction waste, protect the air environment, The effect of protecting respiratory health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The sand and gravel production line waste treatment system of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

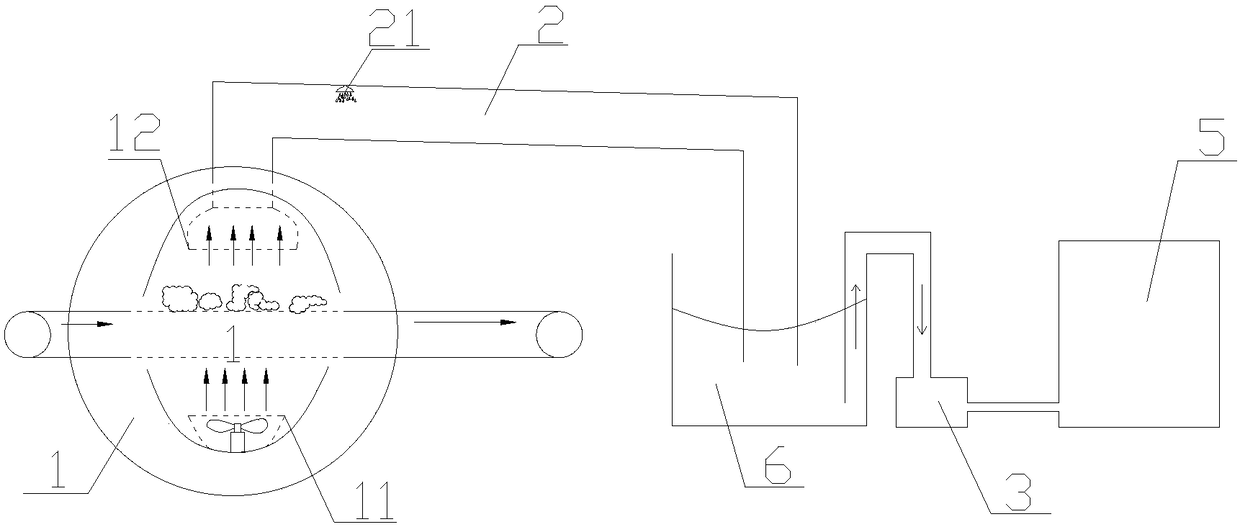

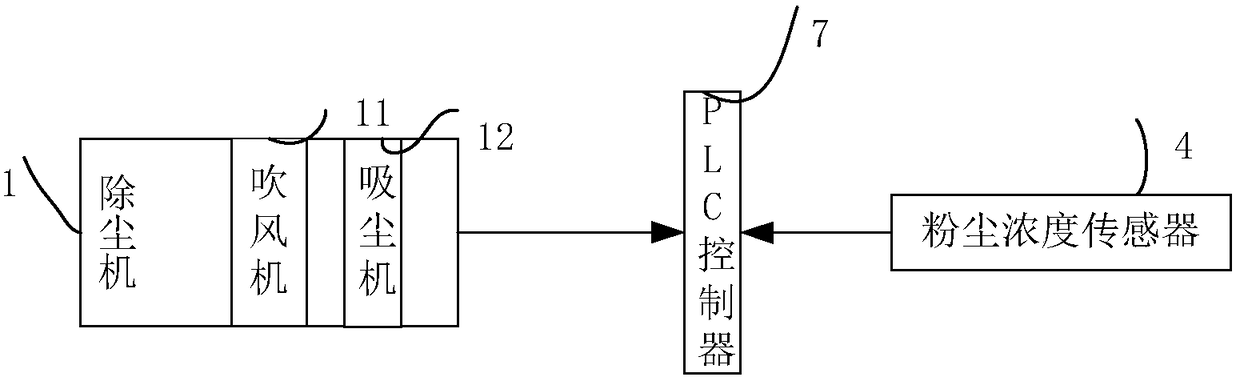

[0012] like figure 1 , 2 As shown, the waste treatment system of the gravel production line includes a sand making machine 5 and a dust recovery system. The dust recovery system includes a dust collector 1, a dust suction pipe 2, a dust concentration sensor 4, a solid-liquid separator 3, and a PLC controller 7. The dust remover 1 is arranged at the inlet and outlet ends of the sand and gravel production line where dust is likely to be generated. The dust suction pipe 2 is arranged at the tail of the dust remover 1 and is connected to the pool 6. The dust concentration sensor 4 is arranged at each of the sand and gravel production lines. At the exit of the production device, the solid-liquid separator 3 is connected to the pool 6, and the PLC controller 7 is connected to the dust col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com