Method for controlling spherulitic radial relative growth rate of iP-1-B by blending iP-1-B with LDPE

A technology of isotactic polybutene and growth rate, which is applied in the field of relative radial growth rate of tactic polybutene spherulites, can solve problems such as limitation and size shrinkage, and achieve the effect of simple operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in combination with specific embodiments.

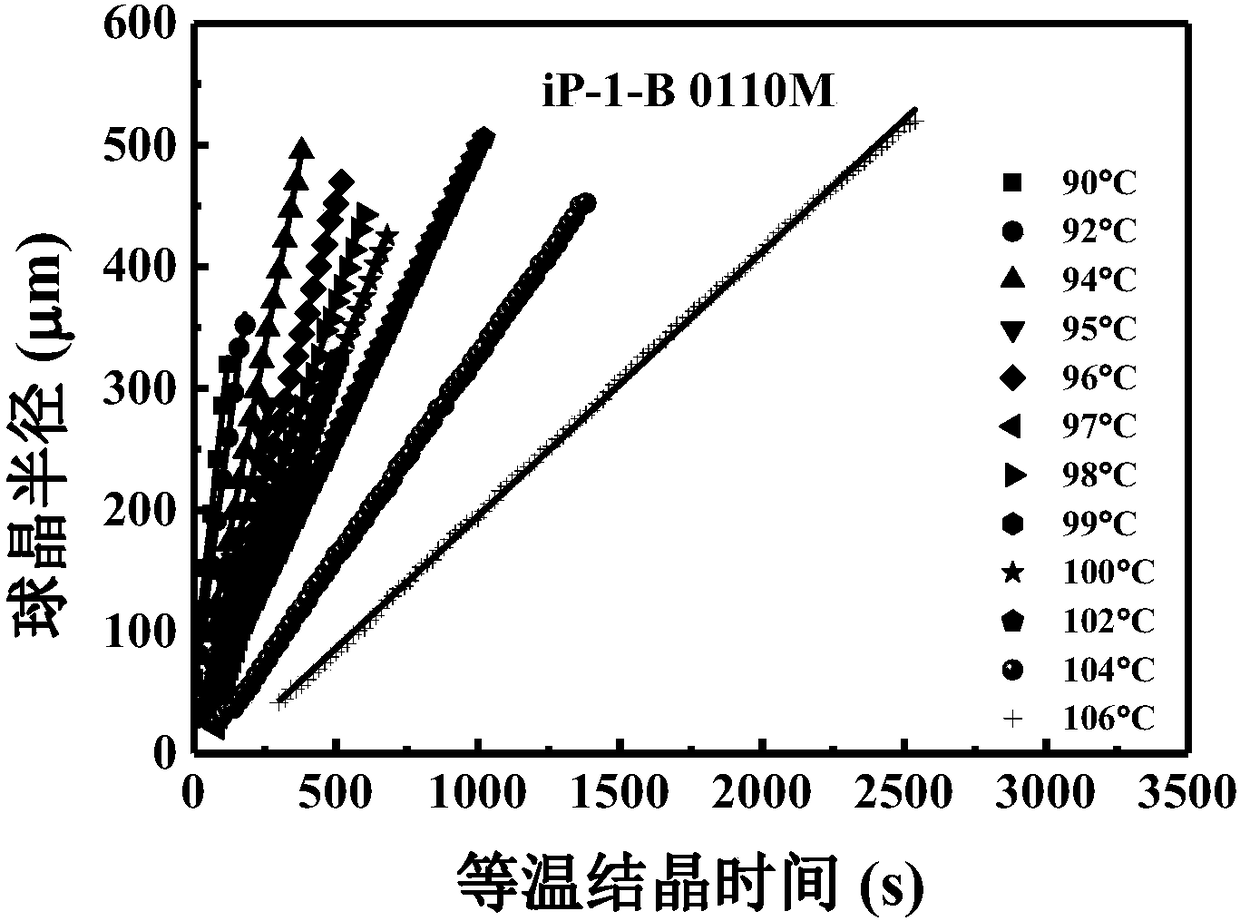

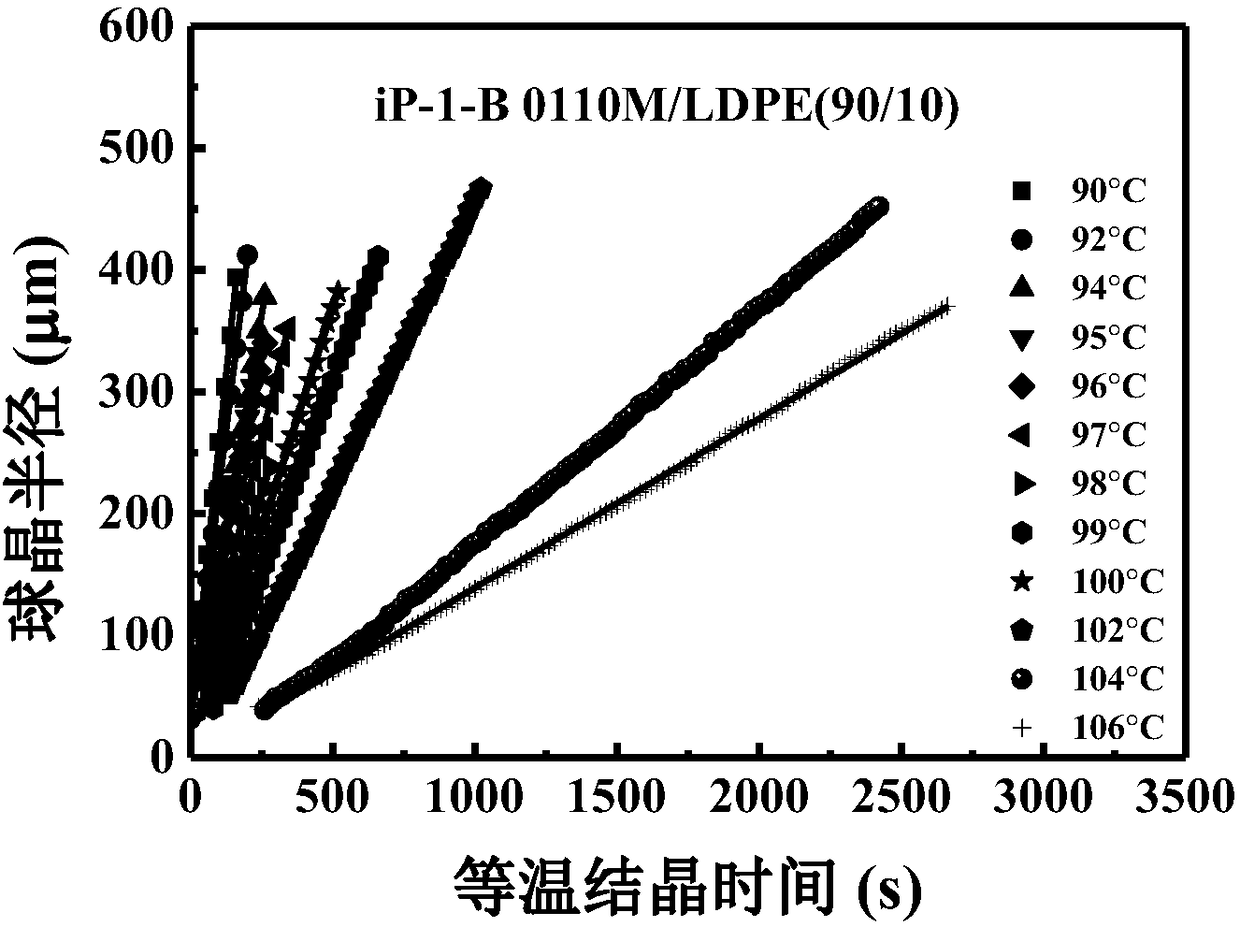

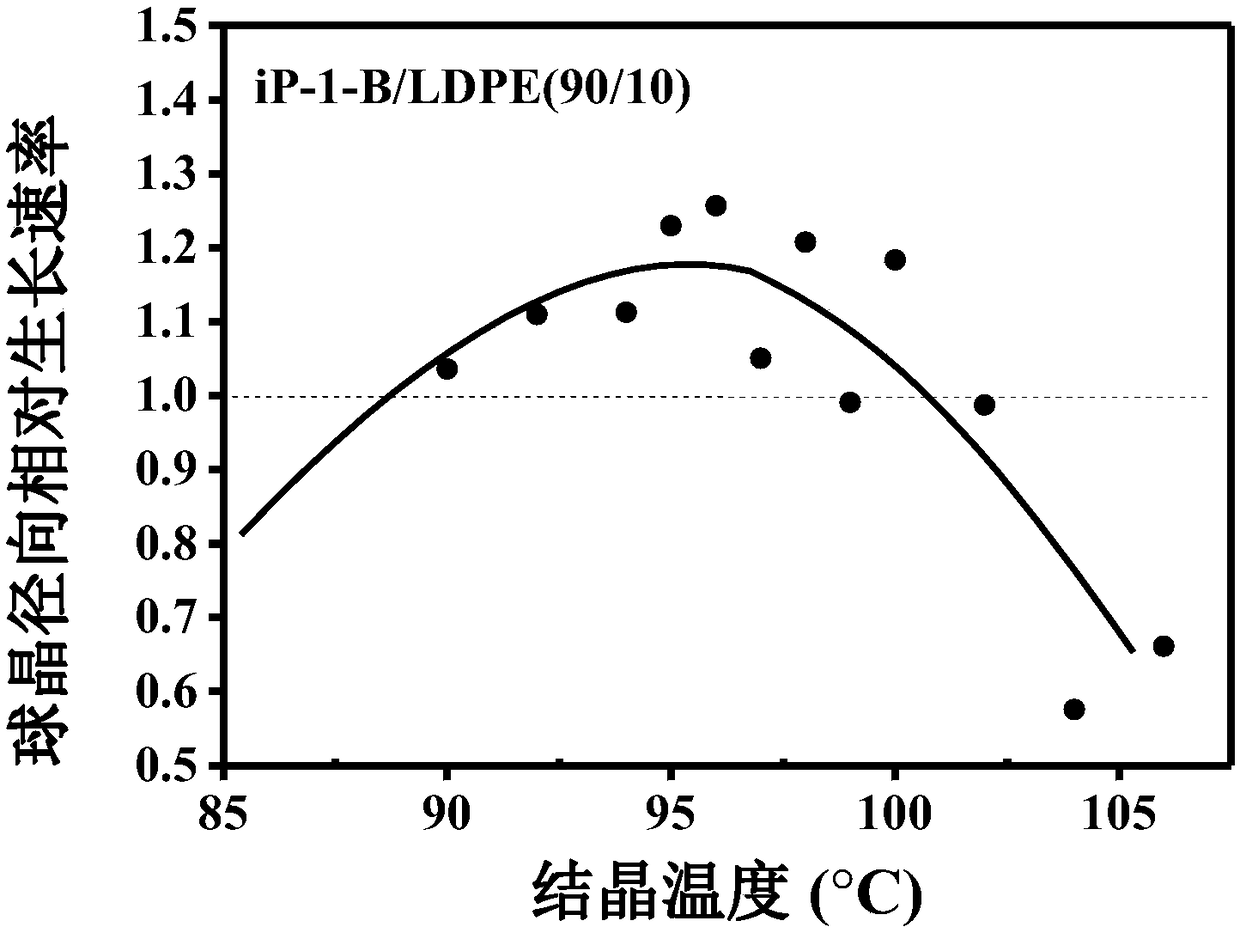

[0016] Weigh 50g of iP-1-B 0110M (Basell company, homopoly iP-1-B, trade mark is PB 0110M, M w =711000g / mol, T m =117°C, T g =-20°C, ρ=0.914g·cm -3 , with a melt flow rate of 0.4g / 10min (190°C / 2.16kg)) and 5.5556g of LDPE 112A-1 (Beijing Yanshan Petrochemical, grade 112A-1, MFR = 2.0g / min, density 0.918g / cm 3 ), after mixing uniformly in advance, in the XSS-30 type torque rheometer, at 180 ℃, blending 12min, rotating speed is 30rpm, obtains the iP-1-B / LDPE blend of 10wt% LDPE content, denoted as iP-1-B / LDPE (90 / 10, that is, the ratio of the added mass of LDPE to the sum of the mass of iP-1-B+LDPE), the obtained sample was cooled to room temperature for later use. 7g iP-1-B and 7giP-1-B / LDPE (90 / 10) were preheated at 180°C for 10 minutes with a laboratory-made flat vulcanizer, and then the pressure was gradually increased to 25MPa by gradually increasing the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com