Method for growing helical carbon nanotubes on wood-derived porous carbon

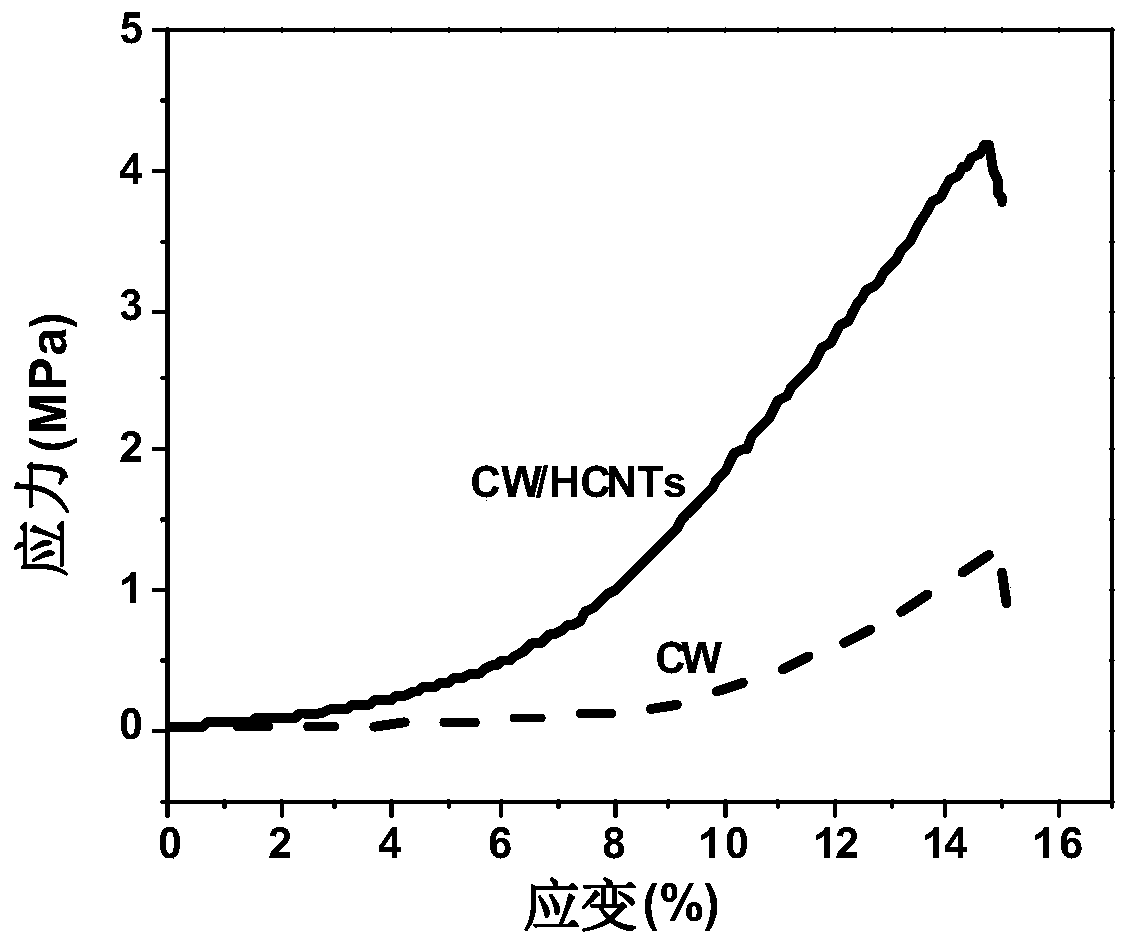

A carbon nanotube and helical technology, applied in the field of supercapacitors, can solve the problems of unsatisfactory electrical conductivity and mechanical properties of carbonized wood, and limit applications, and achieve the effects of facilitating transmission, reducing production costs, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Clean the wood with ethanol and deionized water to remove impurities and residual organic matter on the surface of the wood and pipes. Dry the cleaned wood in an oven at 80°C for 24 hours, and then heat it to 900°C in a nitrogen atmosphere at a constant temperature 3. The carbonization treatment was carried out within hours, after cooling to room temperature, the sample was ultrasonically cleaned with ethanol and deionized water 3 times, and then the sample was placed in an oven at 60° C. and dried for 6 hours to obtain carbonized wood (CW).

[0029] 2. Immerse the CW obtained in step 1 in 0.05mol / L Fe(NO 3 ) 3 In the aqueous solution, reflux at 80°C for 12 hours. After the reaction is completed and the reaction temperature drops to room temperature, the sample is placed in an oven at 60°C and dried for 6 hours to obtain an impregnated Fe(NO 3 ) 3 CW.

[0030] 3. Immerse the Fe(NO 3 ) 3 The CW is heated to 800°C in a nitrogen atmosphere and kept at a constant temperature f...

Embodiment 2

[0035] 1. This step is the same as step 1 of Example 1.

[0036] 2. In this step, Fe(NO 3 ) 3 The concentration is 0.5mol / L, the other steps are the same as the step 2 of Example 1, and the result is impregnated with Fe(NO 3 ) 3 CW.

[0037] 3. Immerse the Fe(NO 3 ) 3 The CW was heated to 800°C in a nitrogen atmosphere and kept at a constant temperature for 60 minutes. After the heat preservation is over, acetonitrile gas was quickly introduced and kept at 800°C for 30 minutes to obtain a CW / CNTs composite material.

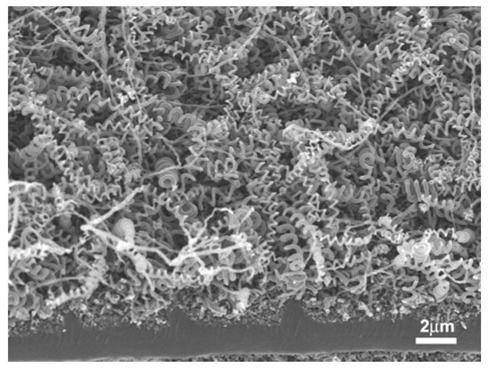

[0038] 4. Immerse the CW / CNTs composite material obtained in step 3 in a mixed acid solution, and soak in a vacuum environment at room temperature for 4 hours. The other steps are the same as step 4 of Example 1, to obtain a CW / HCNTs composite material (see Image 6 ).

Embodiment 3

[0040] 1. This step is the same as step 1 of Example 1.

[0041] 2. In this step, Fe(NO 3 ) 3 The concentration is 1mol / L, the other steps are the same as the step 2 of Example 1, and the result is impregnated with Fe(NO 3 ) 3 CW.

[0042] 3. Immerse the Fe(NO 3 ) 3 The CW was heated to 800°C in a nitrogen atmosphere and kept at a constant temperature for 30 minutes. After the heat preservation is over, acetonitrile gas was quickly introduced and kept at 800°C for 60 minutes to obtain a CW / CNTs composite.

[0043] 4. Immerse the CW / CNTs composite material obtained in step 3 in a mixed acid solution, and soak in a vacuum environment at room temperature for 2 hours. The other steps are the same as step 4 of Example 1, to obtain a CW / HCNTs composite material (see Figure 7 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com